The best welder for beginners is a true MIG welding machine capable of gas metal arc welding (GMAW) using a shielding gas. Plus, you can use it for flux-cored welding without gas.

The MIG welding process is easier to learn than any other welding method. Even a novice welder can quickly start making useful welds with less frustration.

Many gasless-only welders are described as MIG machines. But these only run flux-core welding wire. They lack the versatility and ease of use found in a full MIG—Metal Inert Gas welder.

With this practical process, you can learn to weld popular metals in different thicknesses under a variety of conditions. A good MIG welder can serve your needs long beyond the beginner’s stage.

If you’re a beginner, just learning to weld, an easy-to-use MIG welder makes a great first welder. And there’s a chance it could be the only machine you’ll ever need.

Jump to: Why MIG? | MIG Welders | TIG Welders | Stick Welders

Why Beginners Buy MIG Welders

1. Quick and easy set-up

You’ll have your new MIG welder ready to weld within minutes of unboxing.

- Connect gun (torch) and cable (quick euro-type connectors make this even easier)

- Connect work cable/clamp

- Verify or install a wire drive roller matching the wire size

- Load wire spool

- Connect the power cord to an outlet

- Feed wire into cable liner out to the gun

- Attach contact tip and gun nozzle

- Connect gas if using solid wire

That’s it, your machine is ready to weld!

2. Learn to weld on your own

After just a little practice, you’ll start making simple repairs and projects.

Industrial manufacturers like MIG welding for its adaptability to automated processes. The makers of MIG welders use this flexibility to design feature-packed consumer machines. These help beginners learn to weld more quickly.

Get familiar with welding safety, spend some time with a good welding book, and watch a few how-to-weld videos. Then, set up your new welder, gather a few basic welding tools and some scrap metal pieces, and start practicing. After some trial and error, you will get the hang of it.

Continue reading to see how features of MIG welders and the MIG welding process make it the best for beginners learning to weld.

3. Simple to set controls

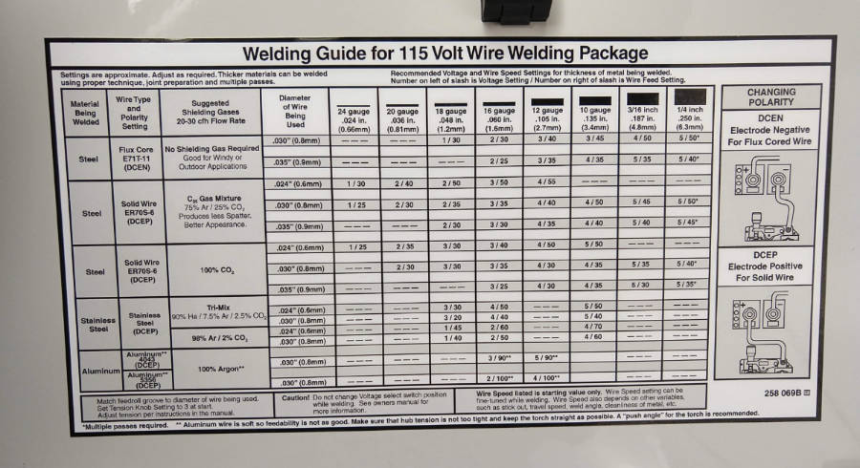

You’ll find a settings chart on the side panel of most welders. Find your material thickness and scan across the table to see the options for gas or no-gas settings with different wire sizes. Use the front panel controls to set initial values for voltage (heat) and wire-speed (amperage).

More advanced MIG welders let you input the material information, and the machine makes the voltage and wire speed adjustments for you. Beginners, and more advanced enthusiasts, will appreciate this feature.

4. Fine-tune settings for the best weld

If the initial settings are not quite right, you can make minor adjustments to the wire feed control to fine-tune amperage. Use the voltage control to make more significant changes. With a little practice, this process becomes second nature.

Advanced synergic welders allow tuning of amperage and voltage settings through a single control knob. This affordable synergic welder helps beginners focus on their technique.

5. Easy weld starts

Some types of welding require scratch or lift start techniques to start the arc that begins a weld. It takes skill to strike an arc and start it in the right place.

To MIG weld, you position the torch over the workpiece. Then pull the trigger on the welding gun to send the energized wire electrode into contact with the material. This completes the circuit and starts the arc.

6. Smart MIG welders require less skill

The best welder must be easy for a beginner to use. Unlike other arc welder methods, with the MIG welding process, you don’t need to control the filler material or the power output as you work.

The welding machine supplies powers, shielding gas, and filler through the MIG gun so that the beginner can focus on mastering the basic joints and welds.

Inverter-based MIG welders use microcontrollers to monitor the arc as you weld. The arc is continually fine-tuned to get the best weld results. They can even compensate for operator mistakes, such as unsteady travel speed and distance from work.

You’re free to focus your attention on learning to control the weld puddle. You’ll do this by regulating the gun orientation and travel speed. You’ll watch the weld pool and control what’s molten when, and for how long.

This learned skill is the key to making sound, uniform welds. While no one is born with this ability, anyone can pick it up through practice.

Beginners make quick progress with MIG because the process lets them concentrate on technique. This makes for a shorter and more enjoyable learning curve.

7. You can see the weld

Since a beginner must learn to control the weld pool, it’s necessary to see it. MIG welding with gas produces an arc with fewer sparks and smoke. It’s much less than stick welding and gives you a clearer view of the weld.

The better you can see the weld puddle and observe the effects of any adjustments or technique changes you’ve made, the sooner you’ll learn to make better welds

Keeping your work area brightly lit will help. Here are good work lights for welding use.

8. Ugly beginner welds can be strong

MIG welders release a shielding gas over the weld, preventing contamination that would otherwise cause porosity (air pockets) and weaken the weld.

This means the MIG process helps make your not-so-pretty beginner welds stronger. It’s easy to make them strong enough for the type of light projects and repairs most beginner welders take on in the learning stage.

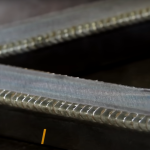

As you continue to work on projects and practice, you’ll soon notice your welds look better. With more uniform weld beads and penetration, your work will hold up to more substantial projects.

9. Less clean-up leaves more time for welding

MIG welding results in very little spatter, and no slag, for easy cleanup. But if spatter becomes a problem, there are tricks to reduce MIG spatter. With a bit of focused practice, a beginner’s skills will improve more quickly.

10. A better welding experience

Automatic gas and wire feed, pre and post-flow burn back timers, 2T/4T switches, and memory presets are only a few of the features making MIG welders easy to learn, productive, and enjoyable for a beginner.

Why MIG Welders Are Popular

11. Welds the metals most beginners use

- Mild steel (low carbon)

- Stainless steel

- Aluminum

12. Effective on a range of metal thicknesses

Providing excellent results on very thin (18-gauge) auto body panels, home-use MIG welders are also effective on moderately thick materials, with some machines capable of welding metal plates up to ½-inch in one pass.

13. Weld indoors or out

Get your best welds while indoors using gas, or even outdoors in a light breeze. Use a screen to prevent the shielding gas from blowing away and leaving your weld unprotected.

If conditions are too windy for MIG welding, or you’d just prefer to leave the bottle in the shop, a quick switch from MIG wire to flux core wire gives you a very mobile outdoor rig.

14. Easy transport to work sites

With many under 40 pounds and some even less than 30 pounds, a small MIG welder is easy to carry to work areas or lift to a storage shelf.

15. Slightly dirty materials are not a problem

While MIG welding with gas requires spotless materials, a switch to flux core welding lets you make strong welds on metals with light rust, paint, or grease. Just what you’re likely to find on outdoor equipment, fences, and black iron pipe.

16. Weld in all positions

Once a beginner can control the weld pool on horizontal surfaces, vertical and even overhead welding becomes possible with a MIG welder.

Upgrade Path for Beginners

17. Beginners don’t need to upgrade shop power

Many affordable multi-voltage MIG welders are now available. If you don’t have access to 230V power, you can teach yourself to weld using 110V power. When the time is right to upgrade your shop’s power, your multi-voltage welder will be ready for 230V.

18. Add a spool gun for aluminum

Many MIG welders are spool gun ready and provide an easy upgrade option for trouble-free aluminum welding. For a top-quality beginner MIG welder with spool gun capability, see our Lincoln 140 review.

19. A multi-process MIG/TIG/Stick welder could be the best choice for a beginner

Tech advancements have allowed the development of simple to use, and portable, three-process welders. You can choose an all-in-one inverter welder that’s capable of MIG, Stick, and TIG welding.

Upgrade by adding process-specific accessories as needed, or choose an all-in-one kit.

For the ultimate in adaptability, many multi-process welders are also multi-voltage capable.

Best MIG Welder for Beginners

Starter Welder – Forney Easy Weld 140 MP

Forney Easy Weld 140 MP

- [VERSATILE FUNCTIONALITY] – The 140 MP is a 3-in-1 (Stick/MIG/DC TIG) machine, offering…

- [EFFORTLESS & PERCISE CONTROLS] – The 140 MP offers a simple start feature and 3-position…

- [WELDER INCLUDES] – 10 foot MIG gun, 8 foot electrode holder, 8 foot ground clamp,…

Starter MIG – Eastwood 135 Welder

Durable Beginner Welder – Hobart Handler 140

Hobart Handler 140

- Occupational Health & Safety

- Country of Manifacturer: United States

- Manufacturer: Hobart

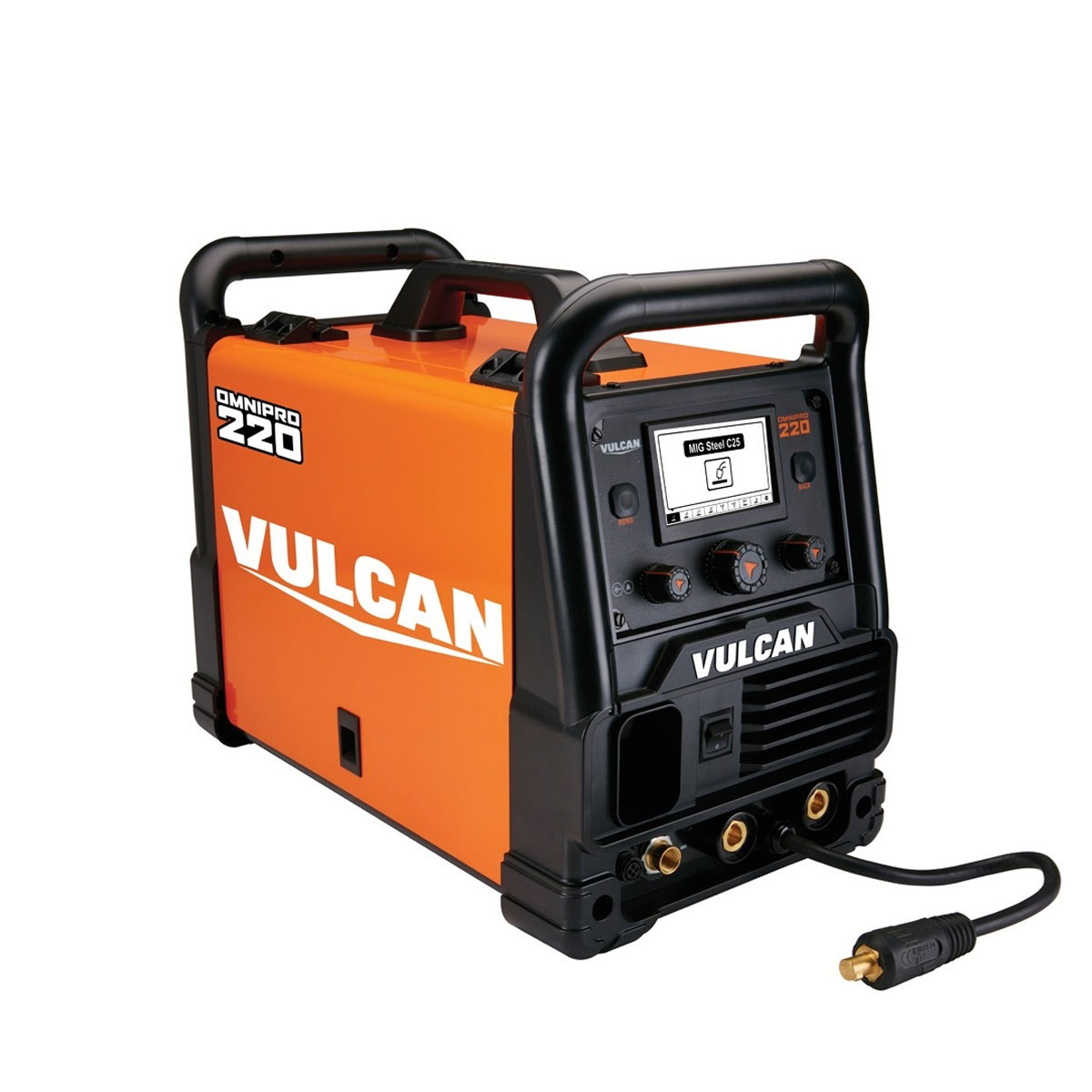

Premium MIG Welder – Vulcan OmniPro 220

OmniPro 220 Industrial Multiprocess

- Multiprocess for MIG, Flux-core, DC TIG and DC Stick welding

- 132 pre-loaded welding programs for easy setup

- 4.3 in. LCD display for process selection and advanced controls

- 120v and 240v power cords included

Is TIG Good For Beginners?

I like how this guy explained it:

“… MIG is like a pickup truck, always useful. A TIG is like a skid steer. It’s the right tool for the right job, but the wrong tool for most jobs. I know a lot of guys that have pickup trucks but no bobcat, but I don’t know a single guy with a bobcat that doesn’t have [a] pickup truck.”“REDONE” on GarageJournal.com

Like modern MIG welders, pickup trucks are reliable, powerful, and easy to use for the operator.

Both are versatile, all-around tools perfect for most jobs

Similar to a skid steer, a TIG welding machine requires extra welding skills to be useful. The formal name of this process is gas tungsten arc welding (GTAW). A TIG torch supplies shielding gas and electrical current through a non-consumable electrode.

The operator must feed filler material to the weld while controlling the heat applied to the weld.

With practice, it’s a useful machine, especially with exotic metals. And in the right hands, a TIG weld can be a work of art.

Using a TIG welder is a lot of fun, and I recommend everybody try it. But TIG welding is a slow process that requires clean materials. It’s better suited to smaller bench-top projects, or when weld appearance is a priority.

A TIG welder is not the best general-purpose machine for basic welding.

But if your focus is on creating custom items like aluminum bike frames or stainless steel exhaust components, then a TIG welder would be ideal for you. And well worth the steeper learning curve.

TIG Welder for Beginners

Weldpro 200A TIG/Stick

Weldpro 200A TIG/Stick

- AC/DC TIG and AC/DC Stick; welding amperage range of 5 – 200A

- IGBT inverter design with automatic overheat and over current welding protection

- Lightweight and portable; power source weighs 31 lbs

Stick Welder For a Novice?

Stick welding also requires user expertise to be an effective welding tool. Another type of arc welder, the stick welder replaces a MIG gun with a simple electrode holder. The consumable electrode (aka stick or rod) contains filler material coated with flux.

Stick welding creates a lot of sparks, smoke, and slag that make it difficult to see the weld. As you stick weld, the electrode gets shorter as filler metal transfers to the weld. You must continually adjust for this and frequently stop to insert a new rod.

Good penetration on thicker materials, the ability to work outdoors, and strong cleaning action on slightly dirty materials are some strengths of stick welding.

You can achieve similar results by switching to flux core wire in your MIG machine.

Stick welding is not useful on thin sheet metal.

Beginner Stick Welder

Forney Easy Weld 298

Forney Easy Weld 298

- [VERSATILE WELDING MACHINE] – The Forney Easy Weld 298 Arc Welder is perfect for a wide…

- [POWERFUL AND EFFICIENT] – With a 90-amp output, this welder can handle even the toughest…

- [WELDER INCLUDES] – 8 foot electrode holder & 8 foot ground clamp.

The Bottom Line

It’s easy to underestimate how useful these machines can be. Many buyers have just one or two welding projects in mind when they purchase their first welder. They may choose an inexpensive gasless or stick welder, only to regret its limitations or difficulty of use.

For the type of hobby and DIY projects most welding novices will tackle, a practical and simple-to-use MIG welding machine is the best welder for beginners.