Tungsten Inert Gas (TIG) welding is a renowned welding method that utilizes tungsten electrodes to fuse various metals.

WHAT IS BLUE TUNGSTEN USED FOR?

Welding Town

WHAT IS PURPLE TUNGSTEN USED FOR?

WHAT IS GREEN TUNGSTEN USED FOR?

The tungsten electrode plays a fundamental role as it conducts the necessary current to establish the arc. Tungsten electrodes can be alloyed with different metals, offering versatility in welding applications. Welders choose from a variety of electrode types and sizes, based on the specific welds and materials involved, and often develop preferences based on their welding style and project requirements. Some TIG electrodes perform optimally with alternating current (AC) rather than direct current (DC). To achieve a precise and clean arc, electrodes are crafted with a tight, sharp point and are devoid of a ground tip.

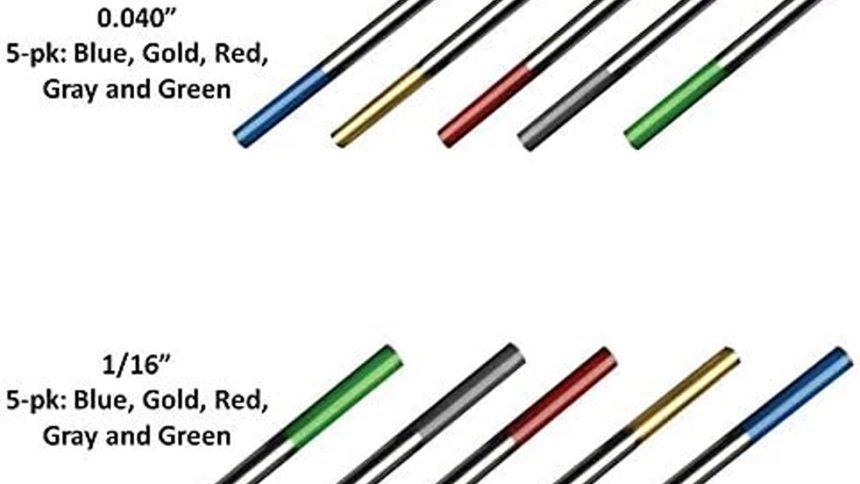

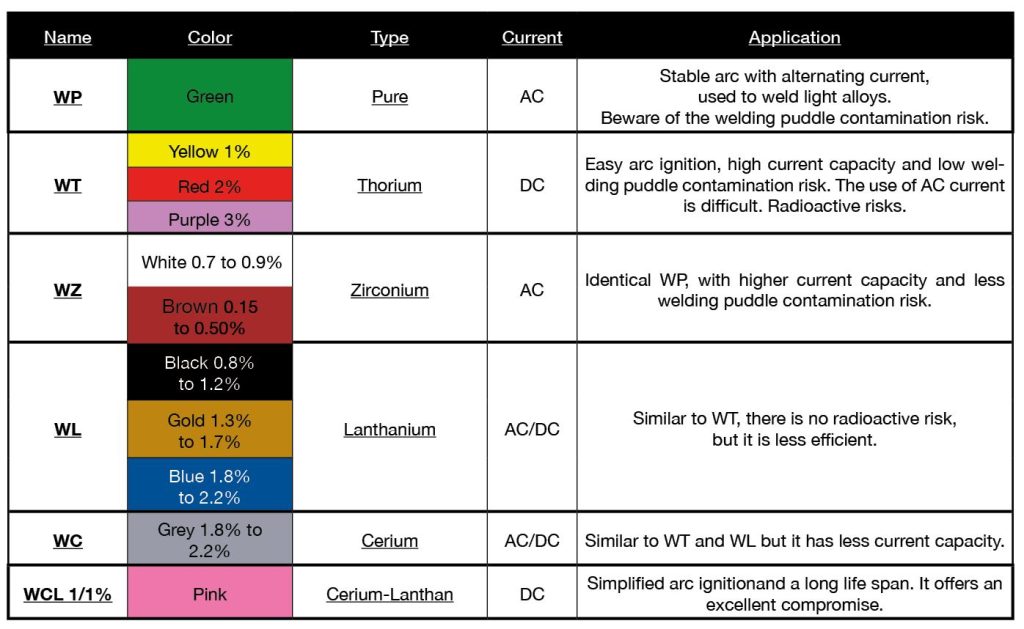

There are numerous types of tungsten electrodes, each tailored for different welding applications. The configuration of tungsten in each electrode type is distinct. Additionally, these tungsten electrodes are distinguished by color codes:

- Pure Tungsten Electrodes – Green

- 2% Thoriated Electrodes – Red

- Ceriated Electrodes – Orange

- Lanthanated Electrodes – Blue

- Zirconiated Electrodes – Brown

- Rare Earth Electrodes – Grey

Please note that the specifics of the tungsten electrode types and their color codes were not provided in the original text, hence, they are not listed here.

WHAT IS BLUE TUNGSTEN USED FOR?

Blue lanthanide tungsten electrodes are highly popular due to their ease of striking an arc and their lower amperage requirements. They perform exceptionally well in both AC and DC welding applications, making them widely used for various welding tasks. Blue electrodes are particularly effective for welding aluminum alloys, magnesium alloys, nickel alloys, copper alloys, titanium alloys, low-alloyed steels, and non-consumable materials.

These electrodes offer outstanding arc initiation, a low burnoff rate, excellent arc stability, and remarkable reignition properties, similar to ceriated electrodes. Lanthanated electrodes also possess the high conductivity characteristics found in 2% thoriated tungsten. In some cases, 2% lanthanide tungsten can replace 2% thoriated without requiring significant adjustments to the welding process.

Lanthanated tungsten electrodes are an excellent choice for welders seeking to enhance their welding capabilities. They work well on both AC and DC welding with electrodes set to negative polarity, utilizing a sharp point, or they can be ball-shaped for use with AC sine wave power sources.

Unlike thoriated tungsten, these blue tungsten electrodes are suitable for AC welding and, like ceriated electrodes, enable the arc to be initiated and maintained at lower voltages. Additionally, the addition of 1.5 percent lanthana in the electrodes increases their maximum current-carrying capacity by approximately 50% for a given electrode size.

WHAT IS PURPLE TUNGSTEN USED FOR?

The purple tungsten electrode, also known as the E3 electrode, serves as a safe and non-radioactive alternative to the thoriated tungsten electrode.

The E3 electrode boasts numerous advantages, including:

Cooler Tip: Compared to its thoriated counterpart, the E3 electrode maintains a cooler tip during welding.

Repeatable Start: It offers superior and consistent arc initiation characteristics.

Enhanced Arc Stability: The E3 electrode exhibits increased arc stability, ensuring a more reliable welding process.

Reduced Consumption: It benefits from reduced electrode tip consumption, leading to longer-lasting performance.

Moreover, the E3 electrode can handle higher current levels than other alternatives and demonstrates improved tip degradation compared to a 2% thoriated tungsten. For instance, when subjected to the same current density, the E3 electrodes maintain a temperature approximately 900 degrees Celsius lower than the 2% thoriated tungsten, making it a noteworthy advantage.

This innovative Rare Earth Blend tungsten electrode comprises 98.34% tungsten, 1.5% lanthanum, 0.08% zirconium, and 0.08% yttrium. As a perfect replacement for red thoriated electrodes, it excels in DC welding applications and proves excellent for welding copper alloys, nickel alloys, titanium alloys, and stainless steel. The E3 electrode’s performance and versatility make it a highly desirable choice for welding applications.

WHAT IS GREEN TUNGSTEN USED FOR?

Green TIG welding electrodes are pure tungsten electrodes primarily employed for AC welding, particularly with aluminum and magnesium materials. Their popularity stems from their cost-effectiveness; they are widely used due to their affordability. However, it’s important to note that they have a tendency to burn up faster than other alloyed electrodes. TIG welding tungsten electrodes are distinguished by different colors, including grey tungsten, purple tungsten, green tungsten, and others, which indicate their chemical compositions.

The green tungsten electrode is favored for its excellent performance in AC sine wave welding, forming a stable balled tip that ensures a consistent arc. Despite their faster consumption rate, they do not ignite as readily as thoriated or ceriated electrodes, which continue to be the top choices among many welders.

PURE OR GREEN TUNGSTEN ELECTRODE

Pure tungsten electrodes, containing 99.5% tungsten, are known for their easy balling ability. The balled tip shape contributes to the excellent stability of the arc. These electrodes perform effectively when working with magnesium and aluminum alloys, making them suitable for applications with low to medium amperage requirements. They are particularly well-suited for AC power supply welding.

When heated, pure tungsten electrodes form a clean, balled tip, providing excellent arc stability for AC welding with a sinusoidal wave. They are particularly advantageous for AC sine wave welding, especially when working with aluminum and magnesium materials. However, pure tungsten electrodes are not commonly used for DC welding due to their inability to produce the strong arc initiation associated with thoriated or ceriated electrodes.