MIG Welding can be a difficult process, but having the right shade can make your task easier and safer. The most common issue MIG welders face is damaging their eyes because their shade is not protective enough. It is a difficult task on its own, but the answer lies below. So, what is the best shade for MIG welding?

The answer is dependent on the amount of amperage you are using, but you should aim for a shade between 10 and 13. The higher the number, the darker the shade. The lower the shade number, the more light you will see while welding, which is what causes damage to your eyes.

Safety is the most important benefactor of choosing the right MIG welding shade, but it is not the only reason to look into it. In this article, you will get a look into the benefits of choosing the right MIG welding shade, as well as a look into the process of MIG welding and how it differs from other forms of welding.

What Shade Is Best for You?

To determine the best shade for you, consider the amperage you are using in your welding and act accordingly. If your amperage is not high you will want to not get darker lenses because it will block out almost all of the light. The amperage and your shade lens work in tandem and to get the best results, the numbers have to be there.

Another factor to consider is what type of steel you are welding. Mild steel, flux core, and aluminum all play a factor in what kind of equipment you should have and in how much amperage you should be using. You can easily be confused as to how much light you see through your lens if you use the same shade for all amperage levels and steel.

For example, if you are using 100 to 175 amperage on aluminum steel you will want a lens with a shade of 11, but that same amperage on flux core steel would be best with a shade of 10. It all varies and if you are someone that works with a lot of different steels and amperage levels, it is best to diversify your equipment.

Luckily, new technology is allowing for more diverse products for MIG welders. Some of these new products offer convenience and safety for welders and are eliminating the need to purchase multiple glasses and shades. Before getting into some of these new tools, let us first make sure to understand what shade is safe for welding, to begin with.

What Shade Is Safe for Welding?

Though the shade you should be using for each welding project varies, it is important to know what the standard shade for safe welding is. Typically ranging anywhere from a shade of 8 to 13, these are the shade levels to consider when purchasing new equipment. However, there are few precautions you can take before purchasing.

- Research the type of steel you will be welding

- Understand the amount of amperage you will be dealing with

- Use different shades while someone else is welding to get an idea of your comfort

- Trial and error

Everyone’s eyes are different and what may be safe for someone else may not be safe for you. Go in prepared so that you avoid any early harmful situations that will compromise your vision and make your eyes sensitive. In the next section, you will get a better understanding of the amperage to shade ratio that will help you make your pick.

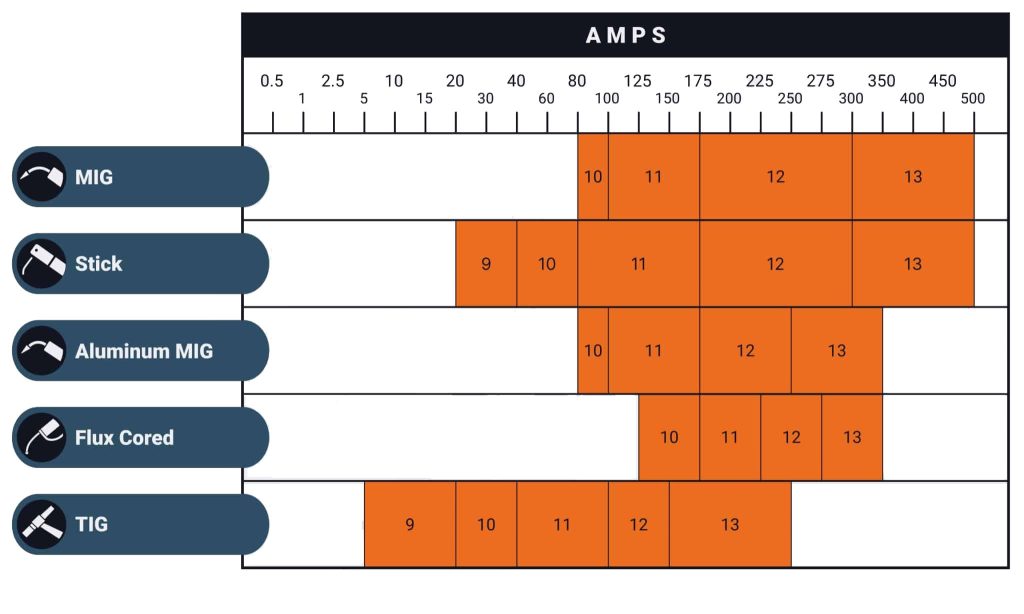

Amperage to Shade

To better understand the relationship between amperage and your lens shade, this next section will use tables to breakdown all the numbers you should know. Aluminum, flux core, and mild steel will be the examples of steel used to help you determine what shade is best for MIG welding each. Use these tables as a reference for future welds.

Mild Steel

| Amperage | Shade Lens |

| 80-100 | 10 |

| 100-170 | 11 |

| 170-300 | 12 |

| 300+ (Usually up to 500) | 13 |

Aluminum

| Amperage | Shade Lens |

| 80-100 | 10 |

| 100-170 | 11 |

| 170-250 | 12 |

| 250+ (Usually up to 350) | 13 |

Flux Core

| Amperage | Shade Lens |

| 125-175 | 10 |

| 175-220 | 11 |

| 220-275 | 12 |

| 275+ (Usually up to 350) | 13 |

Breakdown

Although some numbers are similar, particularly with aluminum and mild steel, they are not completely reflective with each other and are very different from flux core. Different steels create different reactions when welding, which is the reason for the different variations of amperage. Create a ratio table suitable for you if necessary.

Be sure to understand what kind of material you are using before deciding on your lens. The amperage on some steels can be very volatile and can make you have to switch your lenses frequently. For reasons like this, lenses with adjustable shades are highly recommended. There will be more about this later on in the article.

Lenses can go up to a shade of 14, but these lenses are so dark that they oftentimes block out all light and make it difficult to weld at all. Every situation differs, but there is one important factor that makes it nearly impossible for all individual welders to follow the same numbers when deciding what shade is best for them.

Eye Sensitivity

Keeping your safety in mind, it would be unwise to recommend the same shade for every person. Your eye sensitivity is one of the biggest determining factors when choosing the best shade lens for you. If your eyes are naturally sensitive, a shade of 14 may be your best choice, but still may not be the best recommendation due to vision.

You can consider going up one shade based on the amount of amperage you are seeing in your welding. For example, if you are welding aluminum with an amperage of 100-170, consider using a shade of 12 instead of a shade of 11. You might sacrifice a bit of visual clarity while welding, but your eyes will have an extra layer of protection.

If this option still does not offer enough protection for you, you can always go for the shade of 14. To give you an idea of the level of the shade of the 14, this is the same level of shade people use during a lunar eclipse. Test your eyes before making any decisions and try to choose the best shade sooner rather than later.

The earlier you can choose the best shade lens for you, the less your vision will be impaired. Even if you have great vision and non-sensitive eyes before going into MIG welding, not using the right protection will leave you susceptible to harmful lights and can progressively worsen your vision over time.

Best Welding Glasses by Brand

Now that you have a better understanding of what you should look for when choosing the best shade lens for you, it is time to discuss some of the go-to brands on the market. Safety and protection should be the top priority, but there are glasses options aside from helmets that offer a hint of style as well.

- Phillips Solar Eclipse Glasses (Shade 14)

- Shade 10 Goggles (Shade 10)

- Insight Welding Glasses (Shade 12)

- Servore Auto Shade Darkening Welding Glasses

A few of these options are made specifically for one shade, but the severe auto shade comes in options of shade between 5 and 13. There are many other options on the market, but these are some of the top-rated products today. Let us get into some of the benefits and features of the welding glasses listed above.

Phillips Solar Eclipse Glasses

With a shade of 14, these types of glasses are usually recommended for unique situations such as someone with sensitive eyes or a welding project that will see very high levels of amperage. These glasses have the look and feel of regular sunglasses while offering protection from the most harmful of lights.

The downfall to these glasses is that because they are a shade 14, they are difficult to see out of. Many welders avoid glasses like the Phillips solar eclipse glasses because they impair their vision too much while working. You will also want to consider goggles or a helmet if you are looking for equipment that offers more protection for your face.

Shade 10 Goggles

Shade 10’s are rare in the market. They are dark enough to not be practical for light welding at a home garage, but not dark enough for welding with high amperage. Where these come in handy is when you are welding in tight spaces where a full helmet will not fit. They also have a slick design that gives them a retro look.

These goggles are light and convenient and can be worn over your prescription glasses. They also offer added protection through side guards. Keep the amperage to shade ratio table in mind when considering these goggles. These are a good addition to your arsenal if you do a lot of light welding projects.

Insight Welding Glasses

The Insight welding glasses come in a shade of 12 and are convenient not only for their sleek sunglasses-like design but for the level of protection they offer. The shade of 12 is a sweet spot for most welders as they can be used for several welding projects with various amounts of amperage. A few other reasons to consider these include:

- Reasonable price point

- Sleek and lightweight design

- Case and microfiber bag

- Refunds available if needed

Insight welding glasses make a great choice for MIG welders. They are versatile, strong, and offer great protection from high amperage. Their downfall is that because they are designed like sunglasses, they do not offer much protection for the rest of your face. Use it in tandem with other protective equipment.

These are also easy to travel with and protect. The benefit of the sunglasses-like design is that you can preserve them like would with a pair of Ray-Ban’s or Oakley’s. Weld and look good and protected while doing so and then use the microfiber rag to wipe your glasses before storing them away for your next use.

Servore Auto Shade Darkening Welding Glasses

The most versatile product on the market for welders. The Sevore welding glasses allow you to switch anywhere from a shade of 5 to a shade of 13 and the controls are easy to use. Along with the convenience of being able to adjust your level of shade, these glasses use a strap for fitting and offer more protection than typical glasses would.

This is a new technological advancement for welders, but one that comes with many benefits. The variety of options these glasses offer are enough to compete and win over other competing brands. As always, you should make sure these are comfortable for you and that the benefits are relevant as well. Some of these benefits include:

- A frame that gives you the option to fit your prescription lens

- Shock and heat resistant

- Adjustable shades ranging from 5 to 13

- Purchasable faceguard that is compatible with the glasses for added protection

- Lightweight and easy to use in tight spaces

These are more expensive than some of your other options, but the quality is worth the price. They are also stylish and have a futuristic look to them. Most welding projects can be done with shade ranging from 5 to 13 so with these glasses you will not have to purchase multiple glasses with different shades.

Making Sure Your Shade Lens Is Intact

So, you have the equipment, you found the best brand and shade for you and now you want to put it to work, but not so fast. As mentioned before, safety is the most important thing to consider when MIG welding and you want to make sure you are in the best position to safely succeed every time you weld.

- Check your lens before every weld to make sure there were no cracks. Your previous weld may have gone well, but there can always be lasting effects after you finish up. Even the smallest of cracks can lead to harmful effects. The quality of your lens is important and you should make sure to buy a durable product.

- It is not enough to buy goggles or a helmet with the right protective lens. Doing the research and making sure they are as durable as they are protective can be the difference in successfully MIG welding or walking away with injuries and harmful exposure to your eyes. Make protection your number one priority.

- Have the same level of precaution with all of your equipment including your helmets and faceguards. Also, be sure to follow safety guidelines and apply all of your gear safely and weld with caution.

The perfect shade lens is obsolete in helping you if you do not help yourself and create the safest welding procedure you can. Check off every step above before moving beginning your welding. Regardless of the type of welding you are doing, it is a good bit of knowledge to know if these shades are compatible for other forms of welding.

Are These Shades Compatible For Other Welds?

Although this article deals with shades for MIG welding, it is important to familiarize yourself with other forms of welding. With this knowledge, you may be able to transfer some of your MIG welding equipment and use it for other projects. Aside from MIG welding, the most popular forms of welds are:

- Gas Tungsten Arc Gas Welding (GTAW/TIG)

- Shielded Metal Arc Welding (SMAW)

- Flux Cored Arc Welding (FCAW)

A DCEP or Direct Current Positive Electrode is required when MIG welding because it uses shielding gasses to offer protection reacting elements that may harm the melting pool of weld metal. The science behind MIG welding makes it unique to other forms of welding, but the protection your shade offers will work just as will on other welds.

No matter what kind of welding you are doing, be sure to understand how much amperage you will be working with to determine what level of protection you will need. Even if you are primarily a MIG welder, it is valuable to be prepared for all kinds of welding projects.

Conclusion

The best MIG welding shade for you is dependent on a few factors. Consider the type of steel you are working with and the amount of amperage you will be dealing with. The amperage is the key as it will give you the amperage to shade ratio necessary to decide what your best course of action is.

You also will want to remember that what works for someone else may not work for you. If you have sensitive eyes or bad vision you will have to adjust accordingly. While most welding projects can be done using shades ranging from 8 to 13, a project that one can do using a shade of 12, may require you specifically to use a shade higher or lower.

There are brands for all shades, but trial and error along with comfort are some of the determining factors to consider before making your choice. Keep your safety in mind as protecting your eyes and face is more important than the style and design of your choice. When MIG welding, protect yourself at all costs and you will be successful!