Are you thinking about a career in industrial welding or welding engineering technology? Whether you want to enter the welding industry as a capable technician or are simply looking to update your skill set, a welding engineering technology program will help you meet these professional goals.

Flux Cored Arc Welding

Welding Town

Welding requires a specific set of skills, knowledge, experience, and talent. Though there are many welding processes, Flux-Cored Arc Welding (FCAW) is a particularly popular method used throughout the field. Listed below, you’ll find everything you need to know about the flux-cored arc welding process.

Flux-cored arc welding or FCAW, as it is popularly referred to, is one of the most productive manuals or semi-automatic welding processes.

First introduced in the 1950’s as an alternative to manual metal arc welding or stick welding, flux-cored arc welding has since become the preferred welding mechanism for various applications across industry segments.

How Flux-Cored Arc Welding Works

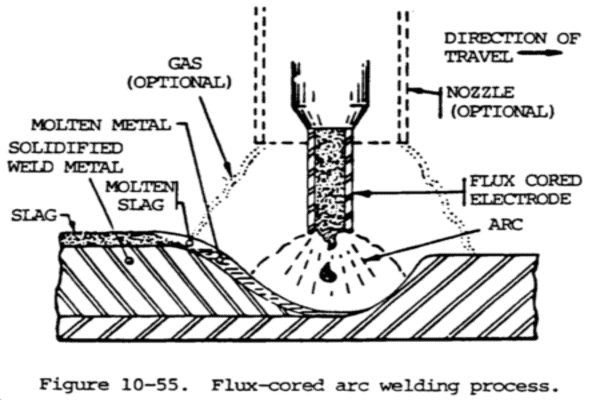

FCAW processes involve using a continuous wire-fed electrode, a constant-voltage welding power supply, and the same equipment used in metal active gas welding (MAG welding). Flux-cored arc welding occurs with or without shielding gas and is way more productive and economical than MAG welding.

FCAW utilizes the heat created by an electric arc to fuse the base metal in the weld joint region. It uses a hollow or tubular electrode filled with a flux compound (also called a flux-cored wire) that protects the weld pool by forming a gas.

Thanks to the penetrative properties of the flux-cored wires and high deposition rates, the FCAW process finds its use extensively in outdoor welding or welding on contaminated materials. Flux-cored arc welding does not need external shielding gas to safeguard the weld from atmospheric elements.

The use of FCAW for thick materials results in “slag.” You can whittle it out later to give it a clean and polished appearance.

Flux-Cored Arc Welding (FCAW) Uses and Methods

The flux-cored arc welding process takes place in two ways. It is primarily divided into two types based on the shielding method:

Method 1: FCAW by using an external shielding gas

The “dual shield welding” method involves using carbon dioxide with flux to provide additional shielding. The most common shielding gases include carbon dioxide and blends of argon (75%) and carbon dioxide (25%).

The shielding carbon dioxide gas, provided externally using a high-pressure gas cylinder, safeguards the weld pool from oxidation. The metal is also protected by the slag formed as a result of flux melting.

This process is generally applied when thicker metals or materials require welding together. The continuously-fed cylindrical electrode enables high deposition rates and amplified production (compared to solid wire or stick electrode).

Perhaps the only drawback of this process is that strong winds may disturb the carbon dioxide gas shielding and affect welding quality in harsh outdoor conditions.

Method 2: FCAW by relying on the flux core to protect the weld area

This method relies on the gaseous protection and slag formed by the flux-cored electrode to cover and safeguard the molten material or metal in the weld. The filler wire core consists of agents that create shielding gases when the welding arc heat burns them.

This type of welding is extensively used in heavy outdoor projects, irrespective of weather conditions. The biggest advantage here is that you don’t need external shielding gas as windy conditions don’t disrupt the welding procedure, making it ideal for external (outdoor) applications.

Equipment Needed for FCA Welds

The basic equipment you will need for flux-cored arc welding includes:

- Source of power: The power source or welding machine provides the voltage and amperage supply that helps maintain the welding arc.

- Welding gun: This type of welding utilized both air-cooled and water-cooled guns. Air-cooled guns are easier to maneuver, but water-cooled guns offer a higher degree of efficiency.

- Welding cables: Connector cables (generally made of copper) help connect the welding gun to your power source.

- Wire feeder: The wire feeding motor drives the electrode through the cable and welding gun and has an electrical rotor connected to a gearbox containing drive rolls.

- Shielding gas equipment: While flux-cored arc welding can occur without shielding gas, you might need a gas supply hose, regulator, control valves, and supply hose for some applications.

Flux-Cored Arc Welding Electrodes

Electrodes are what differentiate flux-cored arc welding from MIG welding. While the latter uses solid wires as the filler material or filler metal, the former involves using electrode wires with a hollow flux-filled center. The electrode wires fill with flux, shielding the weld joint from corroding or contaminating due to natural elements.

Which Metals Can Be Welded with FCAW?

FCAW is among the most popular welding processes because of its flexibility and versatility. Metals like cast iron, stainless steel, carbon steel, high-nickel alloys, and low-alloy steels can be easily welded using the flexible FCAW process.

What Are the Advantages and Disadvantages of FCAW?

Advantages

The flux-cored arc welding process finds its use in industries like construction, heavy equipment repair, structural steel erection, shipbuilding, etc. The primary reason for this is that, unlike most other welding processes, FCAW works on all kinds of materials even if contaminated (except for dealing with contaminants like oils, water, and paint).

It can dissolve mill scale and rust, too.

Here’s a look at some of the most significant pros of flux-cored arc welding and the factors that make it essential today’s world:

- This welding method has higher deposition rates (per hour) compared to other techniques.

- The flux core welding process is excellent for welding dirty, rusted, or contaminated metals.

- This welding process is ideal for all welding positions and outdoor welding activities because of the flux shield.

- The flux-cored arc welding process is quite easy to learn and master.

- This welding method does not require a high level of manual dexterity (as in TIG welding).

- FCAW needs very little (extra) equipment, making the welding method convenient.

- FCAW results in better mechanical consistency, strong weld joints, and fewer weld defects.

- Ideal for metals like stainless steel, carbon steel, high-nickel alloys, and low-alloy steels.

Disadvantages

While the FCAW process offers high deposition, protection against the wind and other atmospheric elements, and a host of other benefits, there are a few limitations or restrictions that you should know.

- Since the FCAW [process is not fully automated, there can be a lack of precision due to manual or mechanical errors

- Working near toxic fumes or smoke can be hazardous, and hence, this type of welding must occur in an area that is well ventilated.

- The cost of an FCAW wire (electrode wire) is more than a solid electrode wire.

- The removal of slag is essential to achieve a smooth, finished weld surface.

- The FCAW welding method involves the usage of expensive equipment (compared to other welding processes).

Common Issues and Troubleshooting

Factors like electrode angles, wire feed speed, arc voltage, electrode extension, and travel speeds can prove the difference between a perfect weld finish and a defective one. Here are some of the most common problems you are likely to face when working on a flux core weld and how to deal with them or prevent them:

- Common wire feeding problems like bird nesting or burn back can cause tangling or extinguish the arc during the welding process. It is best to ensure an appropriate wire feed speed (rate) and distance less than 1.25 inches between the workpiece and contact tip.

- The wrong drive roll tension can also cause the wire to tangle or flatten. You can use U- or V-shaped grooves in the wire feeder and then set the right tension.

- Slag inclusions can prevent the weld’s full penetration due to an incorrect travel speed, heat input, or travel angle. Always clean your weld work between passes and maintain appropriate heat input and travel techniques.

- When the gas from the heated-up flux-cored wire electrode gets stuck in the metal, it can lead to porosity. Ensure you avoid excessive voltage and remove any dirt, dust, paint, oil, rust, or moisture accumulated on the base metal.

Differences Between FCAW, GMAW, and SMAW

FCAW vs. GMAW

Metal Inert Gas (MIG) welding, GMAW, or Gas Metal Arc Welding involves using a continuous solid wire electrode along with shielding gas.

Gas metal arc welding is a common welding process used for vehicle manufacturing, industrial production, construction, and aerospace. Since this type of welding uses gas externally, the wind can hamper the process. GMAW finds its use as a semi- or fully-automatic welding technique.

While FCAW is quite similar to GMAW, the biggest difference is that it doesn’t require you to have an external shielding gas. It revolves around a continuous wire feed process. There are two separate processes associated with flux-cored arc welding, one of which involves using shielding gas.

The other one relies on self-shielding agents (produced when fluxing agents decompose within the welding wire).

FCAW vs. SMAW

Shielded Metal Arc Welding SMAW, also referred to as “stick welding,” is a welding technique used on all ferrous materials. The electrode coating helps de-oxidize the weld area. This generates a shielding gas that protects the weld area from atmospheric contamination.

SMAW finds its use both indoors and outdoors for welding low-alloy and high-alloy steels, nickel alloys, carbon steel, and cast iron (like FCAW). Just like flux-cored arc welding, SMAW, too, creates a layer that you can chip off later.

Flux-cored arc welding is a semi-automatic or manual welding technique that is rarely used indoors. It is generally used outdoors or on contaminated materials. In this case, an electric arc fuses the base material with a continuous filler metal electrode. The shield gas offered by the flux helps protect the weld pool from atmospheric elements.

10 Tips to Improve the Quality of Your FCAW

While the flux-cored arc welding technique has been viable and convenient for several years now, that doesn’t mean the process doesn’t have its own set of pitfalls. As highlighted above, you might face certain challenges with the weld arc area, electrode wires, welding equipment, arc stability, arc length, shielding, voltage, and more.

Here are some pro tips to ensure that your weld joint is of the highest quality and free of complications –

- Use an anti-spatter spray on your part to avoid molten metal from making a mess.

- Avoid burn-back by ensuring the appropriate wire feed speed and MIG gun-to-workpiece distance.

- Always use knurled V- or U-groove drive rolls in your wire feeder to prevent your wire from tangling.

- Make sure there is sufficient space in the weld joint for multiple weld passes.

- Maintain a steady travel speed to avoid undesirable slag inclusions.

- Use a chipping hammer or wire brush to get rid of slag before moving to your next weld pass.

- Maintain appropriate heat input, voltages, and filler wire feed speed to avoid excessive or less-than-ideal penetration.

- Prevent porosity in welding by cleaning any grease, rust, coating, oil, dirt, paint, or moisture from the base metal before you begin.

- It is best to use a filler metal with added de-oxidizers to prevent contaminated welds.

- Maintain a proper electrode stick-out or extension after the step mentioned above.

Flux Core Welding vs. Other Types of Welding

Flux core welding is often compared to stick and MIG welding, and while it can be similar to these methods, it’s also unique in many ways. Let’s discuss how.

Flux Core Welding vs. Stick Welding

The primary difference between stick welding, also known as shielded metal arc welding (SMAW), and flux core welding is the physical structure of their electrodes.

Stick electrodes are metal rods coated in flux. As you weld, the metal center melds with your metal base while the flux casing melts and releases gas to protect the molten metal from contamination.

Flux core electrodes have a metal exterior that contains flux on the inside. Additionally, FCAW electrodes come in a spool and are fed through a semiautomatic welding gun managed by the welder. On the contrary, stick electrodes are long rods attached to an electrode holder managed by the welder’s hand.

Both welding types are self-shielded, removing the need for a gas agent like carbon dioxide. Because stick welding does not require a gas shield, it is also portable and fit for outdoor use.

SMAW also leaves behind slag that requires cleaning between each pass. However, it has a lower deposition rate than FCAW, making for a slower process. Stick welding is common in construction, pipelines, shipbuilding and underwater welding.

Flux Core Welding vs. MIG Welding

MIG welding, also called gas metal arc welding, uses a welding gun that is fed a solid wire from a spool. FCAW also receives a wire from a spool, except the wire is tubular instead of solid.

The shielding process is another difference between these welding types. As indicated by its name, GMAW requires a gas shield to protect the weld pool. The welding gun contains a nozzle that sends gas through it along with the welding wire to ensure a clean process.

Because MIG welding requires a gas shield, little splatter occurs, minimizing slag and making for an overall cleaner weld. However, it’s not fit for outdoor use as a draft can easily blow away the gas shield. It is also less portable because it requires transporting both the MIG machine and the shielding gas.

MIG welding is more expensive than FCAW and less compatible with various welding positions due to a high heat input. However, the MIG machine eases use, making it simple to learn.

MIG welding is also more versatile, as it can be used on multiple metals and alloys. Industries like manufacturing, automotive maintenance and production, pipe welding, construction, and shipbuilding use this type of welding.

Flux Core Welding Frequently Asked Questions

Is Flux Core Welding as Strong as MIG?

Because flux core wire is tubular and MIG wire is solid, many are inclined to believe MIG wire is the stronger of the two. However, both flux core and MIG welding wires meet the American Welding Society tensile strength standard of 70 KSI. Measuring which weld is stronger would come down to analyzing the welder’s skill.

Is Flux Core as Strong as Stick?

The stronger weld would depend on the wire used to perform the process. Both flux core and MIG wires come in various tensile strengths. However, the wire you select should correlate with the tensile strength of the metal you’re welding.

Aside from this, determining which type of weld is stronger would depend on the welder’s experience and technique. Both welding techniques can penetrate thick metals. Therefore, the kind you choose boils down to efficiency and comfortability.

Do You Push or Pull Flux Core?

The flux core welding motion naturally produces slag. Therefore, it’s best to pull away from what you’ve welded. Pushing the wire will cause the flux to become trapped in the melted metal.

![12 Different Types of Welding Processes [The Definitive Guide] 6 12 Different Types of Welding Processes [The Definitive Guide]](https://www.021208.com/wp-content/uploads/2025/01/12-Different-Types-of-Welding-Processes-The-Definitive-Guide-150x150.jpg)