Welding stainless steel is a talent that requires further exposure. People are unclear about where to start and don’t do it often. Iron, chromium, and nickel make up most of the alloy known as stainless steel. Stainless steels are more oxidation and corrosion-resistant than other types of iron because they include chromium. The United States mandates a minimum chromium content of 10.5%. The advantages of learning how to weld stainless steel and the requirements are covered in this article.

If you’re thinking of learning welding stainless steel, this comprehensive guide is a must read.

021208.com

Choosing the Right Material and Equipment

There are a few factors to consider while selecting the appropriate supplies and tools for your welding projects. It would help if you decided how to employ the welding supply and equipment like welding helmets. Are you going to use them for a short-term or long-term project? The cost of the supplies and machinery should be taken into account second. Is the investment worthwhile?

The quality of the welding gloves supplies and machinery must be taken into account third. Will they be resilient enough to sustain the strain of your project? Finally, it would be beneficial if you considered the accessibility of the supplies and machinery. Are they available locally, or do you have to order them specifically?

A project’s success or failure may depend on selecting the proper tools and materials. Before choosing a choice, make sure to give your alternatives some thought.

Why Stainless Steel?

Stainless steel is a common material for goods and applications that need to be strong and long-lasting for various reasons. Because stainless steel is resistant to corrosion, it won’t corrode or degrade over time. It also has a very long lifetime and is simple to maintain. Stainless steel is perfect for devices that can resist extensive usage since it is also incredibly strong and robust.

Check before welding

You should check a few things before welding, such as the power source, consumables, and equipment. The power source is the most important thing to check, as it needs to be properly set up and connected to the welding machine. The consumables need to be checked to ensure they are compatible with the power source and the equipment. The equipment should be checked for any damage or wear, and the welder should be properly trained and certified.

Study the Metal to be welded

When you are ready to weld; it is important to study the metal you will be welding. It will help you to determine the right welding technique to use, as well as the right welding rod. The metal’s thickness, type of metal, and the presence of any coatings will all affect your welding process. By studying the metal, you can ensure that your weld will be strong and long-lasting.

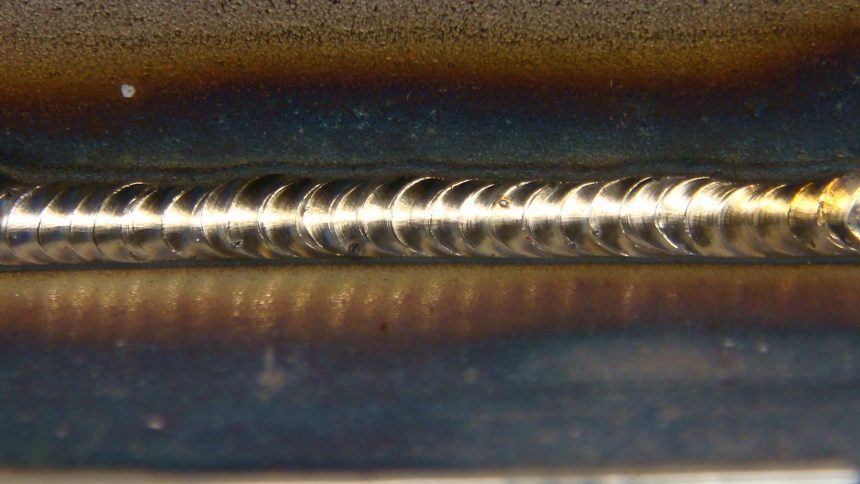

Resistance Welding Stainless Steel

Due to its excellent corrosion resistance and capacity to tolerate high temperatures, stainless steel is a common material for resistance welding. When resistance welding stainless steel, care must be taken to prevent material damage from the heat of the welding process. The weld region should be clear of debris, and the welding conditions should be closely monitored to prevent damage.

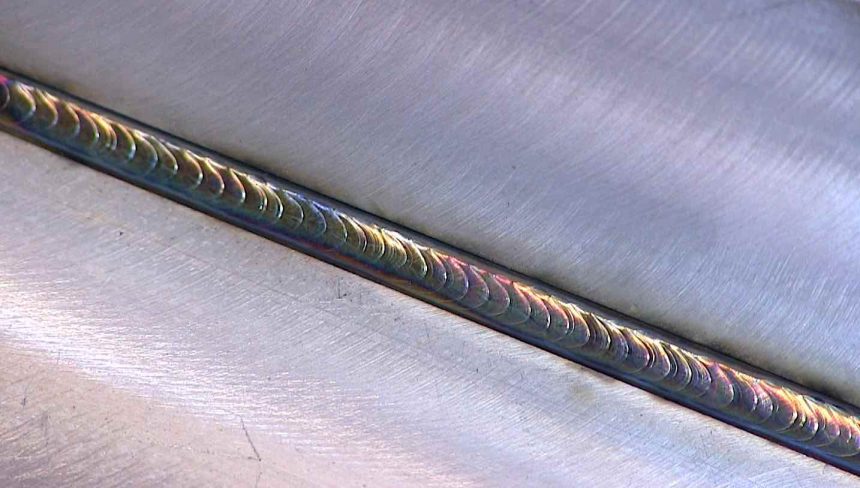

Advantages of Welding Stainless Steel: stainless steel has many advantages, including its resistance to corrosion, strength, durability, and aesthetic appeal. Stainless steel is an alloy of iron, chromium, and other metals that provides superior resistance to corrosion and staining. It is ideal for various applications, from food preparation to medical equipment. Stainless steel is also much stronger and more durable than other metals, making it ideal for structural applications. And because it is non-reactive, it can be used in various environments without fear of rust or other corrosion. Finally, stainless steel has a bright, shiny finish that is highly prized in many applications.

Common Issues When Welding Stainless Steel

This welding has a few typical problems. The possibility of the weld becoming brittle and breaking readily is one problem. Another problem is that it may be difficult to view the weld, making it challenging to determine if it was correctly completed. Additionally, welding with stainless steel may be difficult, and successful results depend on competent welders.

Welding stainless steel is a talent that requires further exposure.

021208.com

What is the process of welding stainless steel?

Welding is a straightforward technique. The area that will be welded must first be cleaned. Impurities will be produced in the weld by any dust or particles on the metal. The metal that has to be welded must then be heated. An oxy-acetylene torch is often used for this. You need to add the filler metal once the metal has been heated. The two stainless steel parts are connected by a metal rod. Finally, cooling the weld region would be beneficial. Either quenching it with water or allowing it to cool naturally is used.

Will Stainless Steel Welding Damage the Weld Area?

In most cases, stainless steel welding doesn’t harm the welded region. However, there are some circumstances where it can be damaged. The weld can be damaged if the weld area is not properly prepared. The weld may be harmed if the welding procedure is not carried out properly. If the welder is not experienced, it can damage the weld.

With these tips in mind, you should be able to weld stainless steel like a professional.

What are the safety precautions while welding Stainless Steel?

A few things to remember to create a secure weld. First, because stainless steel contains more carbon than conventional steel, it’s crucial to utilize a welding rod made particularly for stainless steel. Second, it’s crucial to use less welding current than you would for standard steel because stainless steel is more susceptible to heat distortion. Finally, letting the weld cool gradually is crucial to prevent cracking.

Conclusion

The use of stainless steel in several projects and applications is fairly widespread. Due to its resistance to germs and stains, stainless steel is often used in kitchens and bathrooms. The bathroom, where many people use the sink and mirror every day, is where it is most handy. Although welding stainless steel isn’t tough, there are a few more things to remember when finishing the process. Please feel free to contact us at any time if you have any concerns regarding welding stainless steel or if you’d like a project quote.

![12 Different Types of Welding Processes [The Definitive Guide] 10 12 Different Types of Welding Processes [The Definitive Guide]](https://www.021208.com/wp-content/uploads/2025/01/12-Different-Types-of-Welding-Processes-The-Definitive-Guide-150x150.jpg)