Generally, TIG welding provides more flexibility and versatility when compared with other types of available welding processes. Though, it is also a tough job to handle TIG welding while doing projects. Hence, with some extra effort and good practice one can be more proficient in using a TIG welder and can smoothly perform TIG welding tasks.

Welding Tips: The Secret to Success When TIG Welding

Welding Town

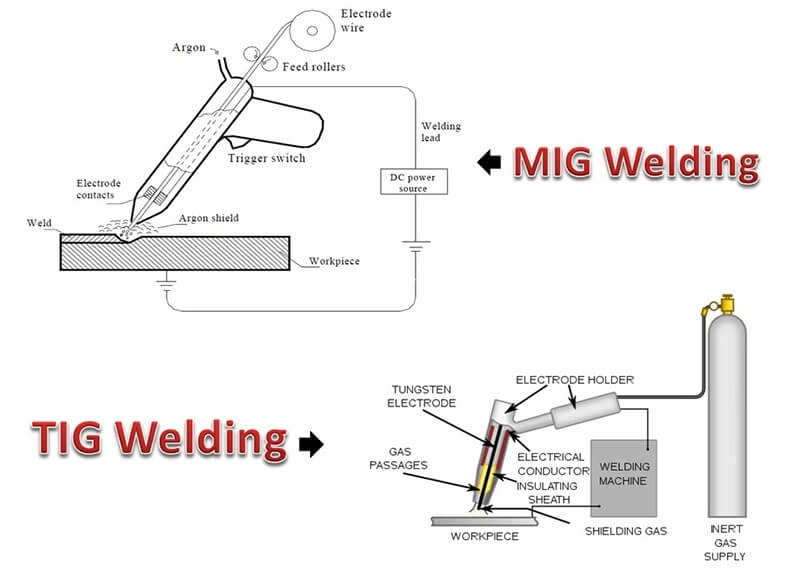

Typically, Tungsten Inert Welding or we can say, TIG welding or Gas Tungsten Arc Welding (GTAW) is a type of arc welding that is used to produce the high-quality pure weld. Due to this reason, this TIG welding has commonly been used in extremely sensitive projects where there is no compromise on quality. For instance in nuclear aviation, pharmaceutical industries, and food and beverages. Here MIG welding has been used to perform jobs by using a metal coil that is fed continuously with the gun, On the other hand, the TIG welding can cause the base metal to be meltdown when the filler metal is hand-fed within the molten pool. Thus, this type of welding can be done on different base metals such as stainless steel, aluminum, carbon steel, and other non-ferrous metals.

So one cannot give much better advice than this, if you are serious about becoming a great TIG welder then you should develop the highest level of patience along with great practice sessions. For us, this advice work as a wonder, thus we make this our motto and always suggest new TIG welders follow this in their baby footsteps. Though, if holding a welding torch in your hands before initiating the project doesn’t excite you then we recommend switching your welding type with this as it will not be a good option for you as a career.

We don’t mean to dishearten you, but we still want people who are serious about TIG welding they should continue their passion as their career. To give our new welders more ease we are here to give people some amazing tips and tricks. We are sure that these tips can help you in learning, improve your skills, and keep you in the right direction. Pectizing these tricks in your daily routine will give you confidence, make you draw a consistent arc, more control over the weld puddle, and help you in producing great welding results every time.

Top 15 TIG Welding Tips for Beginners

These are the simple yet effective techniques that can help you in completing your welding job in time while making your life even easier.

1. Weld by using the minimum power source

When one begins practicing their TIG welding then he/she must always make sure to mark the minimum power settings into the puddle. At the start, you should give your weld puddle enough energy to sustain. It is essential to remember that TIG welding is based upon penetration. So giving too much power means you are going to burn down the base metal right away. Hence, your power level is always an important part of your welding technique.

2. Keep your metals clean

Remember, TIG welding always needs a clean metal to perform an effective job. Without clean metal, you cannot create a solid weld or sturdy arc. You must have a dedicated brush Top useful TIG welding tips and tricks. Even before beginning a new project putting some extra minutes into cleaning can always bring amazing outcomes.

3. Using the correct tungsten

When working on a different surface while using a TIG welder, you will notice that you need different tungsten for this task, for instance, the welder who is working with aluminum, there is a large chance where you can use green tungsten. Also, red tungsten is linked with steel. So there is no need to be afraid and memorize all. With practice, you will learn more about equipment.

4. Thickness of Tungsten must be considered

Every pro-TIG welder will always say that the thickness of the tungsten is always a matter. So if you got something too large that you will need more heat to begin your process, especially when striking the arc. Whereas when you are dealing with too small tungsten then you might encounter a chance to risk your base metal getting overheated and damaging the welds.

5. Identify the time to regrind your tip

Knowing the tip of your tungsten is important to make sure the tip is touching the weld puddle. You might get forced to regrind the tip. Over time the tungsten develops a ball. And you will find the low-quality tungsten arc. Since quality is the key part of TIG welding it can never be compromised. So if you find a tip causing negative aspects on the quality then for the welder, take it seriously as a warning alarm to smooth the tip by regrinding it. Also, there is a chance of an encounter with an accident while balling with the project, hence make sure you save your time by keeping ready several tungstens.

6. Keep consistent during the welding process

During TIG welding the welder is required to maintain its focus from beginning to end. Make sure you have already eliminated the distractions from the welding environment that may cause disturbance and interruption during your welding process. As it is always a good choice to stock up some additional fillers rods quite closely with you, so you can easily grab them without adding breaks into your workflow.

7. Equip with the proper safety equipment while grinding

For some beginners that don’t realize the amount of safety, they should follow with TIG welding. Though, tig welding setup spatters and sparks free that don’t even produce any fume or smoke. But they should know that tungsten electrodes are slightly radioactive. Especially when you are grinding the TIG welder to create a fine tip. Wearing a welding respirator that is designed to protect the airway passage should become imperative. Afterward, it is important to pick a place where there is minimalistic dust and dirt and place your welder to keep the tip safe. Also, add decent ventilation within your workspace for your regular welding.

8. For your electrode grinding stay consistent

Consistent is the key especially for beginners so when you grind the tungsten then going lengthwise is always a smart choice. Hence, this way you are onto creating an even result whenever you do welding. Mostly, the TIG welders can use a tungsten sharpener though, for the beginners who just initiate the journey, it is suggested to go with a bench grinder. Hence, it will do a marvelous job. Depending upon your choices and the vast options available, we still want you to do grinding jobs without contaminating your electrodes.

9. Get to know about your shielding gases

Commonly, 100% argon is used as a shielding gas for doing TIG welding. Furthermore, the ratio of argon and helium 75:25 respectively is also a popular option among welders. The more you increase the helium in your shielding gas, the more temperature will begin to fall which in other words can cause problems in striking the arc finely. So if you add 100% helium as a part of your shielding gas then you will find it much more difficult in initiating the welding process. So set your shielding gas at 15-20 cubic feet/hour during your learning on how to weld through TIG. A higher setting can eventually blow out your weld.

10. Whenever possible use bigger rods

The logic behind using the bigger rod is quite simple. So if you are having a larger rod then you will find ease in the feeding process. The standard rod with TIG welding equipped usually holds a diameter of 3/32 or below. Hence, going with a 1/8 inch diameter rod will facilitate you more in learning the process.

11. Angle of your rod and torch shouldn’t be the same

If you are putting rod and torch at the same angle while you are working with your TIG welding equipment then you will make the heat have a “bounce” during your work. Since at this process you are enabling the rod to properly meltdown before you want that melting to happen. Hence, it will create an inferior bead. So to save you from such a mess you should feed the rod into the welding pool.

12. Instead of an abrupt end, slowly reduce your arc

When the welder is welding by using TIG weld at a defined temperature then he must keep the foot pedal or with any type of temperature control mechanism around 3/4th of the way down. Doing this will give you the ability to let the arc trail off when you reach the ending points of the weld. Shutting down the welder machine suddenly will eventually cause a high rate of cracking of the base metal.

13. MIG and TIG are often interchangeable

There is a chance (very often) when the welder uses a wire from MIG welding to create a TIG weld. Although it’s not a regular thing often there is some chance of your welding equipment getting interchanged. Most likely multi-process welding machines also offer 3 or 5 in one welder.

14. Protect yourself from shocking

The most easiest and common way to decrease the shocking hazard threats for your welding is to create a non-conductive environment by placing something on it. The use of welding gloves is common that can prevent you from shocking your arms. Consider wood products as you’re another good option. Remember your sweat can conduct more electricity that needs great care to tackle. So keep resting your arms that hold the torch.

15. Thin gloves sometimes work great with TIG welding

If you are on wearing thin gloves on your hands that are used to feed the rod then you will have a more real and improved texture in the process. If your gloves are bulky, thick, and heavy then it will prevent you from having maximum control over the welding process. This way it will affect the overall quality of the results. Also, it will help you in learning how you can feed the rod by using your fingers more realistically.

Frequently Asked Questions (FAQs)

1. How do I fetch better value at TIG welding?

TIG welding is a skill that takes practice to get good at. The best way to get better at TIG welding is to weld as often as possible. Try to find a welding buddy and practice your techniques together. There are also plenty of online resources and welding classes available that can help you improve your skills.

2. How do you practice TIG welding?

There are a few ways to practice TIG welding. One way is to find a scrap piece of metal and practice welding different joints.

3. Is TIG welding the most difficult to learn?

No, TIG welding is not the hardest to learn. It is often considered one of the easier welding processes to master. This is because TIG welding requires a lower heat input than other welding processes, so there is less distortion and warping of the material.