When deciding between TIG welding and MIG welding for a specific job, it’s important to consider several key factors that can help determine the ideal process to apply. Both TIG and MIG welding have their own advantages, and understanding these benefits can assist in making an informed decision for your particular application.

In this article, we will explore and compare these two widely used welding processes to provide a reference for understanding their similarities and differences. By examining the characteristics of each process, we can gain insights into their respective strengths and applications. Let’s delve into the details to facilitate your decision-making process.

How does TIG welding work?

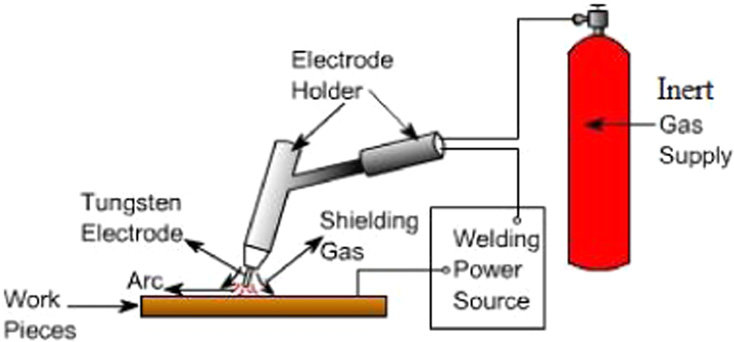

TIG, which stands for Tungsten Inert Gas, is a welding process also known as GTAW (Gas Tungsten Arc Welding). This particular welding process utilizes a non-consumable electrode, typically made of Tungsten, to create the weld. The current is delivered to the welding arc through this electrode. TIG welding is classified as a fusion welding process, as it involves melting the base materials together to form a weld joint.

In TIG welding, there are four essential components, each playing a specific role in the process. These components include a tungsten electrode, a welding torch, a filler metal, and a shielding gas.

During TIG welding, the operator holds the welding torch with one hand while simultaneously feeding the filler rod into the welding puddle using the other hand. It is important to note that the tungsten electrode should always remain separate from the workpiece throughout the welding process. This separation ensures that the electrode does not come into direct contact with the molten metal or the base material. By maintaining this separation, the operator can control the heat input, guide the filler rod, and create precise and controlled welds.

TIG welding machines offer the flexibility to use either direct current (DC) or alternating current (AC), depending on the type of metal being welded. The choice between DC and AC depends on various factors, including the specific characteristics of the metal and the desired welding outcome. To explore this topic in more detail, you can refer to our comprehensive guide titled “TIG Welding: A Complete Guide.”

Advantages of the TIG welding process

TIG welding, despite not being the most commonly used welding process in the industry, offers several advantages that make it highly valued:

- Precision: TIG welding allows for precise control over the amount of filler metal added to the welding puddle. Since the electrode is separate from the filler metal, the operator can accurately control the deposition, resulting in efficient filler metal usage. The amperage control through a foot pedal provides further control within a single welding bead.

- Cleanliness: TIG welding is known for its cleanliness due to its controlled process with minimal spatter. It often requires little to no post-weld cleaning. In some cases, fusion without the use of filler metal is possible, further reducing the need for cleanup.

- High quality: TIG welding produces high-quality welds with minimal sparks and spatter when the welding piece is clean. This makes it suitable for applications that require aesthetically pleasing welds, such as sculptures or cosmetic welds.

- Versatility: TIG welding offers versatility as the same tungsten electrode and shielding gas (typically Argon) can be used for various welding jobs. It is capable of executing all four welding positions: flat, vertical, horizontal, and overhead.

- Wide range of weldable metals: Originally developed for welding magnesium in the aircraft industry, TIG welding has expanded to a wide range of metals. It is commonly used for welding aluminum, magnesium, steel, stainless steel, brass, copper, bronze, Chromoly, nickel alloys, and other metals. It has become a preferred process for welding bike frames, door handles, and various manufacturing products.

These advantages make TIG welding an attractive option for applications that require precision, cleanliness, high quality, versatility, and the ability to weld a wide range of metals.

How does MIG welding work?

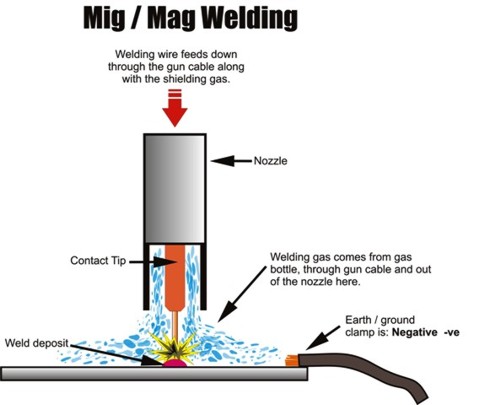

MIG, which stands for Metal Inert Gas, is a welding process also known as GMAW (Gas Metal Arc Welding) or MAG (Metal Active Gas). This particular welding process utilizes a continuous solid wire as both the electrode and filler metal. The wire continuously feeds through the welding gun, delivering the current to the welding arc. MIG welding is widely used in various industries and applications for its efficiency and versatility in producing welds.

In MIG welding, a welding gun or spool gun is used to feed both the electrode wire and the shielding gas into the welding puddle. The electrode wire, which also serves as the filler metal, is continuously fed through the gun. The speed at which the wire is fed, known as the Wire Feed Speed (WFS), is a crucial parameter in MIG welding. Controlling the WFS is essential for maintaining proper arc stability, achieving the desired weld bead size and shape, and ensuring consistent and high-quality welds. Adjusting the WFS allows the welder to control the deposition rate of the filler metal, providing flexibility in adapting to different welding conditions and materials.

Another important aspect of MIG welding is the use of shielding gas. The most commonly used configuration is a mixture of Argon (75%) and CO2 (25%). This gas blend offers several advantages in MIG welding. It helps increase deep weld penetration, allowing for stronger and more reliable weld joints. Additionally, the Argon-CO2 gas blend helps reduce porosity in the weld bead, resulting in a more solid and defect-free weld. The specific composition of the shielding gas can be adjusted based on the welding application and the type of material being welded. By selecting the appropriate shielding gas mixture, welders can achieve optimal weld quality and performance.

Methods of metal transfers for MIG

There are four main methods of metal transfer used in MIG welding, and the choice of method can significantly impact the quality and efficiency of your welding project. These methods are influenced by various factors such as welding parameters (amperage and voltage), shielding gas, and the power source. The method of metal transfer used in MIG welding also determines the suitable filler metal and welding machine, with certain methods requiring advanced machines with specific waveforms.

Here are the methods of metal transfer in MIG welding, presented in chronological order:

- Short circuit transfer: In this method, a short electric circuit is created as soon as the electrode contacts the workpiece. This occurs around 100-200 times per second. A gas mix of Argon (75%) and CO2 (25%) is commonly used. Short circuit transfer is suitable for thinner materials and can be used in all welding positions. It produces less heat, reducing workpiece distortion. However, it may result in lower deposition rates and penetration when used on thicker materials, leading to increased spatter and cleanup time.

- Spray transfer: Spray transfer involves a spray of tiny droplets of filler metal across the welding puddle. The droplets are smaller than the filler material itself. This method requires higher amperage and voltage compared to short circuit transfer, enabling higher speeds and reducing spatter. It is ideal for materials wider than ⅛ inch and is commonly used with a gas mix of Argon (80%) and CO2 (20%). Spray transfer is suitable for carbon steel and aluminum.

- Globular transfer: This method is a combination of short circuit and spray transfer. Large droplets of filler metal, larger than the wire diameter, travel from the arc down to the welding puddle. It uses higher voltage than short circuit transfer, increasing speed but also spatter. Typically, pure CO2 is used as the shielding gas. Globular transfer is productive due to the high voltage but generates more slag, requiring additional cleanup. It is not recommended for materials thinner than 1/8 inch.

- Pulsed-spray transfer: Pulsed-spray transfer involves a cycle of low background current and intermittent high peak current or voltage. This results in the release of tiny droplets from the filler metal toward the welding puddle. The filler metal can be either metal core or solid wires, and the shielding gas is usually at least 80% Argon. Pulsed spray transfer offers faster travel speed, high deposition rate, lower spatter, and reduced material distortion. Operators have better control over arc starts and stops, resulting in improved weld appearance. Welding aluminum with this method requires operator skill.

Each metal transfer method has its advantages and disadvantages, and the selection depends on factors such as material thickness, desired deposition rates, welding positions, and operator proficiency. Understanding these methods allows welders to choose the most suitable approach for their specific welding applications.

What makes MIG welding so special?

There are several reasons why the MIG welding process has gained popularity in the industrial world:

- Ease of use: MIG welding is considered a semi-automatic process where the wire is continuously fed through the gun, eliminating the need for complex manual electrode manipulation. This makes it easier to learn and operate compared to processes like TIG welding. With basic welding knowledge, operators can quickly grasp MIG welding techniques, making it convenient for both operators and companies in terms of training and workshop availability.

- Efficiency: MIG welding offers a balance between speed and quality. It is known for its fast welding speed, but this speed must align with the desired quality. The process efficiency is enhanced by the lower spatter levels, reducing the need for post-weld cleanup. Additionally, the use of automation in MIG welding, particularly with welding robots, further improves efficiency by increasing productivity and consistency.

- Quality: MIG welding can produce strong and visually appealing welds. While TIG welding is often praised for its weld bead appearance, MIG welding can also deliver strong welds with minimal post-weld cleanup, especially when compared to processes like stick welding. The quality of the weld depends on the skill and experience of the operator, and MIG welding is relatively easy to master, resulting in better quality welds when performed by skilled operators.

- High production capabilities: MIG welding is well-suited for high-volume production due to its continuous wire feeding mechanism. The wire spools come in various sizes, allowing for continuous welding without frequent stops, which is common in processes like stick welding. The availability of different-sized filler metal packages caters to various welding needs, including applications in welding robots for continuous and efficient production.

- MIG welding and automation: MIG welding is highly compatible with automation and robotic welding. The semi-automatic nature of MIG welding, with constant wire feeding and defined welding parameters, makes it an ideal process for welding robots. Welding robots can operate in any position, deliver consistent and high-quality welds, and outperform human operators in terms of speed and endurance. They are unaffected by harmful gases and fumes, further contributing to a safer and more efficient welding environment.

Overall, the ease of use, efficiency, quality, high production capabilities, and compatibility with automation make MIG welding a preferred choice in the industrial sector, particularly for applications that prioritize productivity and consistency.