TIG welding was first invented in America ( USA ) in 1936, known as Argon arc welding. TIG allows top-quality welded joints to be produced with inert gas supports with clean welding results. This welding method is an all-purpose welding procedure with regard to the material used, wall thickness, and welding positions.

TIG welding tips, training materials, weld calculators and more. Learn how to TIG weld or improve your skills with Miller TIG welding resources.

021208.com

The advantages of this welding method is producing hardly any spatter and few pollutants while also guaranteeing a high-grade welded joint if used properly. The feeding of welding consumables and the current are not interlinked, so this makes TIG suitable for welding root passes and positional welding.

However, TIG welding needs a well-trained welder to use it with a skilled hand and knowledge of the correct application of voltage and amperage. Those will support the clean and best TIG welding result. And I think these are the point of TIG welding disadvantages.

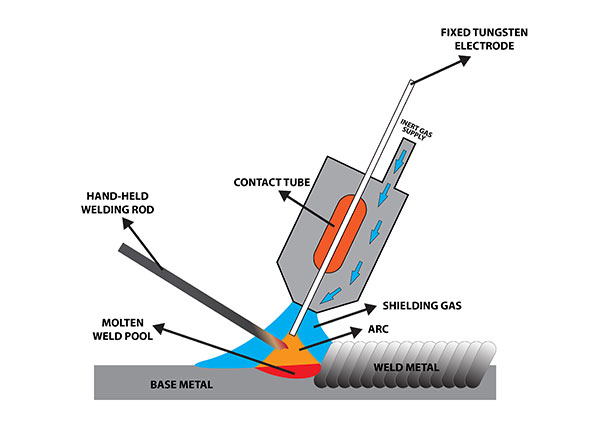

As you can see in that picture, after you pressed the torch’s switch the gas begins to flow. And when the tip of the torch touches the surface of the metal, a short circuit occurs. owing to the high current density at the torch’s tip, the metal starts vaporizing at the point of contact and the arc ignites, of course, covered by the shielding gas.

SETTING THE GAS PRESSURES / FLOWS

The gas flow rate is in l/min and it depends on the size of the weld pool, the electrode diameter, the gas nozzle diameter, the nozzle distance to the metal surface, the surrounding airflow and the type of shielding gas

A simple rule is that 5 to 10 liters of shielding gas should be added to argon as the shielding gas and to the most widely used tungsten electrode diameters, at a rate of 1 to 4 mm per minute.

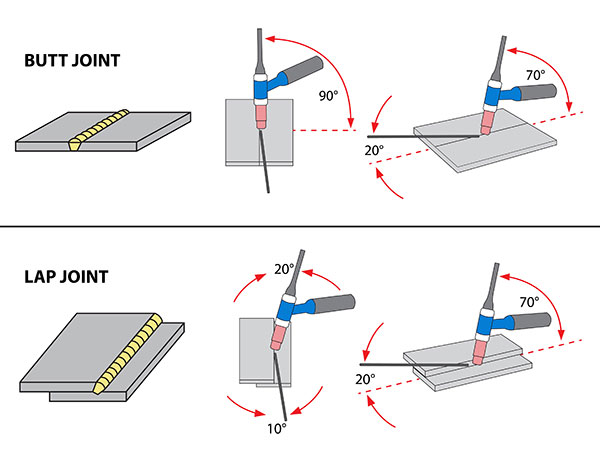

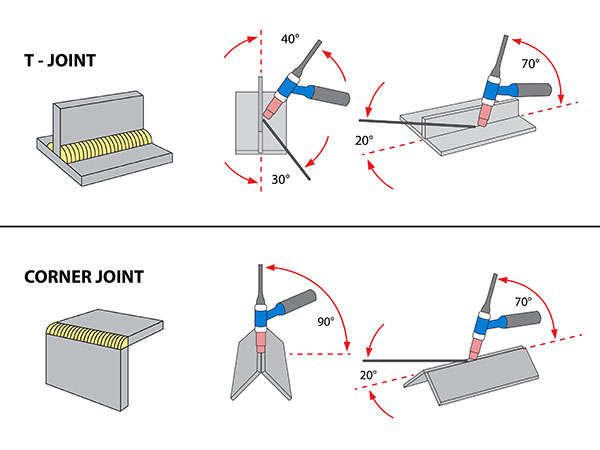

TORCH POSITION

As in MIG Welding, the position of the torch, when you use the TIG Welding method, is also very important. The position of the torch and the electrode rod will affect different welding results.

The Electrode itself is also a welding consumable used during TIG welding. Welding consumables are usually selected in the same way as the type of metal. However, for metallurgical reasons, it is necessary for the welding consumables to deviate from the parent metal when certain alloying elements are used.

Back to the point of torch position. You can apply the different positions of the TIG torch and the electrode rod while welding various metal joints. So the torch position depends on the type of metal joints. I mean there are 4 basic metal joints such as :

- T- Joint

- Corner Joint

- Butt Joint

- Lap Joint

You can apply some of these torch positions to the works that you want to complete. And when you are familiar with the various metal joints welding torch positions, then you can learn about welding parameters.

In the TIG welding process the arc is formed between a pointed tungsten electrode and the workpiece in an inert atmosphere of argon or helium. The small intense arc provided by the pointed electrode is ideal for high quality and precision welding.

021208.com

WELDING PARAMETERS

When selecting the welding parameters, it must be noted that only the current is set on the welding machine. The voltage is determined by the arc length, which is maintained by the welder.

Therefore, the greater arc length needs the higher arc voltage. A welding current of 45 amperages per mm of the metal thickness is used as the reference value for a current sufficient for welding steel to get fully penetration.