Have you heard of fusion welding? Like other welding processes, it’s used to join two or more objects using heat. Fusion welding is unique, however, because of its ability to “fuse” the respective objects. Assuming the objects are made of the same or similar materials, the heat produced by a welding rig will melt their surfaces, thereby allowing the objects to fuse together. With that said, there are five unique types of fusion welding, including the following.

types of fusion welding

Welding Town

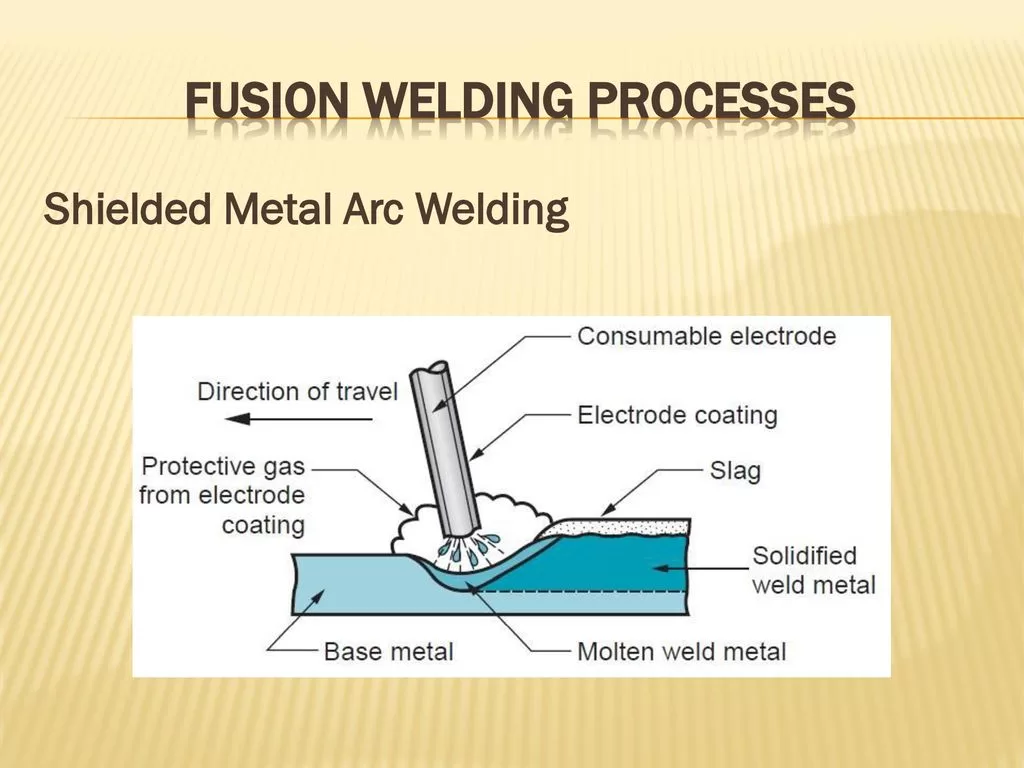

#1) Arc Welding

The most popular type of fusion welding is arc welding. Arc welding lives up to its namesake by relying on an electric arc to join two or more objects. With electric arcs measuring up to 6,000 degrees Fahrenheit, this fusion welding process is highly capable of melting even toughest metals. Furthermore, arc welding can be performed underwater, making it an ideal solution for offshore welding projects.

#2) Laser Welding

Another type of fusion welding is laser welding. Also known as laser welding, it involves the use of light radiation to produce heat. The laser welding rig essentially blasts the surfaces with radiated light. With each blast, the surfaces become a little hotter. As the objects melt, they fuse together.

#3) Induction Welding

In addition to arc and laser welding, there’s the fusion welding process known as induction welding. Induction welding is distinguished from all other types of fusion welding because it’s the only one in which there’s no direct contact between an object’s surface and the heat source. With induction welding, a wrapped coil is used to create a magnetic field that heats metal. The magnetic field quickly heats the metal, causing to melt and fuse together.

#4) Oxyfuel Welding

A type of chemical-based fusion welding, oxyfuel welding involves the use of a flame to heat and join surfaces, with oxygen as the fuel source. Fire, of course, needs oxygen, which is the basis on which oxyfuel welding works. The oxygen fuels the fire to create a hot flame in excess of 4,500 degrees Fahrenheit. Oxyfuel welding typically uses a combination of oxygen and a flammable gas to create a hot flame to join objects.

#5) Solid Reactant Welding

Finally, solid reactant welding is a type of fusion welding that relies on chemical reactions with certain materials to join them. There are compounds, for instance, that create heat when mixed together. Solid reactant welding uses this principle to join two or more objects.