Mention AC/DC to most people, and they will immediately think of a popular Australian hard-rock band. On the other hand, welding professionals recognize it as polarity, referring to the negative and positive poles formed in the electrical circuit as soon as you turn on a welding machine.

AC vs DC Welding

Welding Town

What makes polarity so important in welding? Choosing the correct polarity can ensure the strength and quality of the weld, while the wrong one can cause poor penetration, excessive spatter, and less control of the welding arc.

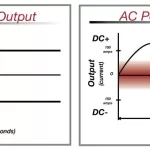

Welding professionals often talk about the pros and cons of AC vs. DC welding. The primary difference is polarity: AC (alternating current) welding alternates rapidly between DC negative and DC positive, while DC (direct current) uses a straight polarity current to supply electricity to the electrode. Which of these you choose will depend on specific factors, so here’s what you should know:

AC welding definition

AC welding means you are using an alternating current in the welding process. The alternating current reverses its direction many times per second. For instance, a 60-hertz current will alter its polarity 120 times per second. Since the magnetic field and current reverse direction, it allows for a steadier arc on magnetic parts.

DC welding definition

DC welding employs a direct current with constant polarity flow in one direction. The current can be positive or negative, with positive polarity flowing from the welder to the workpiece to the electrode and back to the welder. The current flows from the welder to the electrode to the workpiece and then back to the welder with negative polarity. Electrode positive welding offers deeper penetration, while electrode negative provides faster deposition rates.

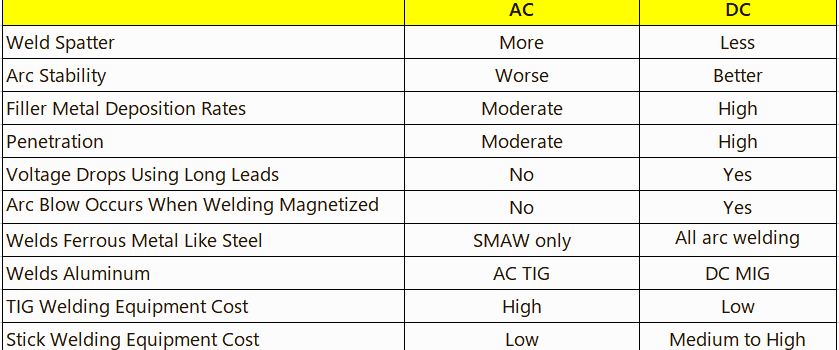

AC welding vs. DC welding

Even though DC welding is preferred for most welding applications, AC welding works well in some specific applications. TIG welding aluminum, welding magnetized metals, downhand welding on heavy plates, with fast-fill electrodes, and welding where the only electrical outlets are 110 volts all lend themselves to AC welding. Unlike DC welding, arc blow is far less noticeable when welding with AC.

On the other hand, direct current maintains a constant and stable arc and is more reliable than AC. It typically produces a smoother weld with less spatter because of the continuous direction of the current. DC also welds thinner materials better than AC, working best with stick welding, stainless steel TIG welding, and vertical or overhead welding.

Electrode negative vs. electrode positive

As mentioned earlier, the DC current can be positive or negative. But how does that affect the welding process?

Sometimes called straight polarity, electrode-negative polarity is preferred for most welding jobs. It produces a hotter arc and faster electrode melting, allowing operators to be more productive and lay down a bead faster. Straight polarity DC will almost always be a welder’s first choice unless a specific need for something else comes up.

Electrode-positive polarity, also referred to as reverse polarity, generates deeper penetration. Even though it is slower than straight polarity, it is usually the choice for welding thick material. The advantage of reverse polarity becomes evident when working with metal more than half an inch thick.

AC welding vs. DC welding: summing things up

| AC Welding | DC Welding | |

| Polarity | Alternating polarity | A single polarity that could be positive or negative |

| Applications | Magnetized metals, aluminum, heavy plates | Stainless steel, overhead, vertical, and thinner plate welding (Most applications) |

| Weld strength | Weaker with more spatter | Stronger and smoother |

| Arc blow | Fixes arc blow issues | Can cause arc blow |

| Arc stability | Arc can be hard to work with | Stable arc |

| Welding machines | Less expensive, portable | More expensive and heavier |

The answer is: it depends on your situation. While DC welding will probably be your first choice, each type of welding has some distinct advantages in specific circumstances. If you’re starting your welding career, DC welding is easier to work with and results in cleaner welds. However, DC welding machines are typically more expensive than AC, prompting beginners to lean toward the more affordable welders.