TIG welding is difficult even under the best of circumstances. It is a skill that requires experience, coordination and a great deal of multitasking expertise. By adding stainless steel as a source workpiece to the mixture, the entire process becomes even more difficult to accomplish with any degree of precision.

How To TIG Weld Stainless Steel Like A Pro

Welding Town

Often, employers hire TIG welding professionals to work on stainless steel. It makes sense to do so. Granted, this action may hinder upcoming projects, but the long-term benefits are undeniable. After all, stainless steel welding is not uncommon. It’s a common metal, a hard, structurally dense alloy that has permeated all corners of life. The work done on such projects is not marred by substandard welding. A poorly welded stainless steel structure may even warp or rust from the weld’s heat. What an unforgivable sin that would be.

Crucial Applications of Stainless Steel in Welding

Stainless steel is not a single metal. It is actually a versatile family of alloys found everywhere. This includes the construction industry, pressure vessels and piping systems. In addition, its ductility and strength make it ideal for large construction projects that require a strong and durable support material.

Even kitchenware and food industry components use certain stainless steel. Corrosion-resistant and chemically neutral grades are favored for such commercial applications. In oil fields and other harsh industrial environments, ANSI and SAE-graded steels offer excellent heat resistance and durability, as well as a degree of resistance to liquid/gas corrosion. So what’s the answer? What are the options when stainless steel workpieces need to be welded? There are many well-known brands of TIG welders on the market to choose from, but even with such a great machine, someone needs to overcome the challenges associated with welding stainless steel.

The First Steps to Mastering TIG Welding of Stainless Steel

The problem is that the alloy contains a large number of graded amalgams. Trace amounts of the metal are added at the heat treatment stage in order to create many members of this metal family. Additives such as nickel and manganese provide unique mechanical and chemical properties to various stainless steel grades. The point is: that while engineers and builders want these properties to be realized, they can complicate TIG welding operations.

It is the job of the TIG welding professional to understand these alloy properties and to know and apply techniques specifically for stainless steel. Equipment selection and setup are also important, but the true professional knows that the first step needs to be performed before applying these requirements to the job. Cleaning and preparation, which is key, is the means to unlocking the entire process.

Preparation Process Guide:

Cleaning metal surfaces of grease, oil, corrosion and other contaminants

Further preparation. Smooth the surface using wire brushes and abrasive tools

Select a suitable inert gas. Hot stainless steel heat affected zones tend to oxidize

Choose a good quality welder.

Applying Professionally Tuned Equipment Settings

Intermediate welders are competent, but tend to take shortcuts. Maybe they’re experienced and think they know everything there is to know about TIG welding, and there may be some truth to their claims, but equipment changes are always changing. At Welding Town, we’re also committed to providing more power, more flexibility, and more features. Professionals know this, which is why they are careful to keep their equipment manuals handy for reference.

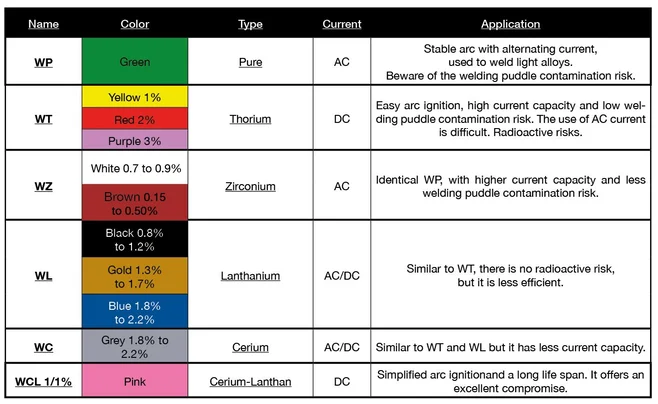

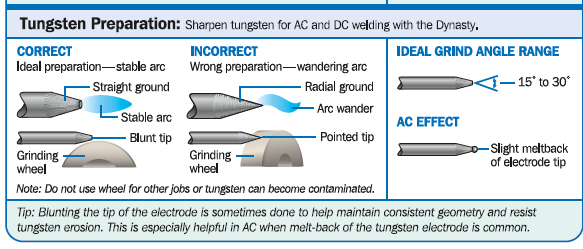

Many welder factories provide data sheets so that welders can get the most out of their equipment. On that table, it’s easy to intuitively see the ideal equipment setup. The amperage and voltage are there to better ensure deep root fusion. Electrode polarity and filler metal selection are also clearly printed. Tungsten cleaning and sharpening, duty cycle settings, and amount of protective gas – all of these variables are controllable. This is where the multitasking aspect stands out and allows professional welders to adjust many settings with confidence.

By the way, reviewing the manual, there is a troubleshooting guide in the back of the book. It will keep seasoned welding professionals on the straight and narrow if unforeseen problems arise during stainless steel welding operations.

Here are some tips and tricks to help professionals avoid common pitfalls when looking for quality, professional results:

Use the correct diameter tungsten rod (see manual datasheet)

Keep tungsten electrodes clean and sharp

Use 100% argon as a protective gas

Manage application heat

Establishing a good, clean electrical ground

Use DCEN (Direct Current Negative)

A Return To The Basics: TIG Welding For Stainless Steel Projects

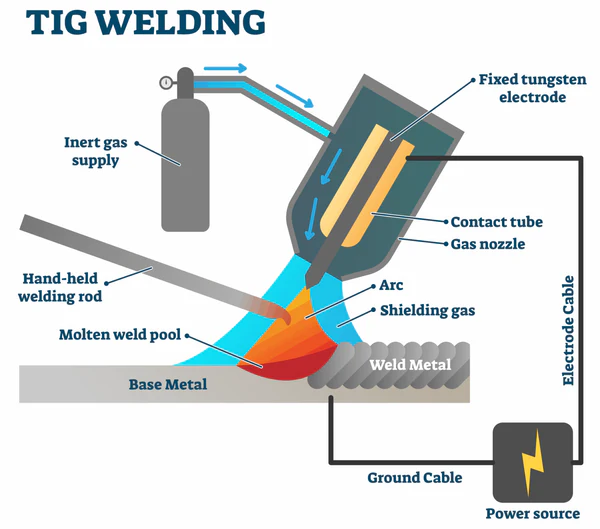

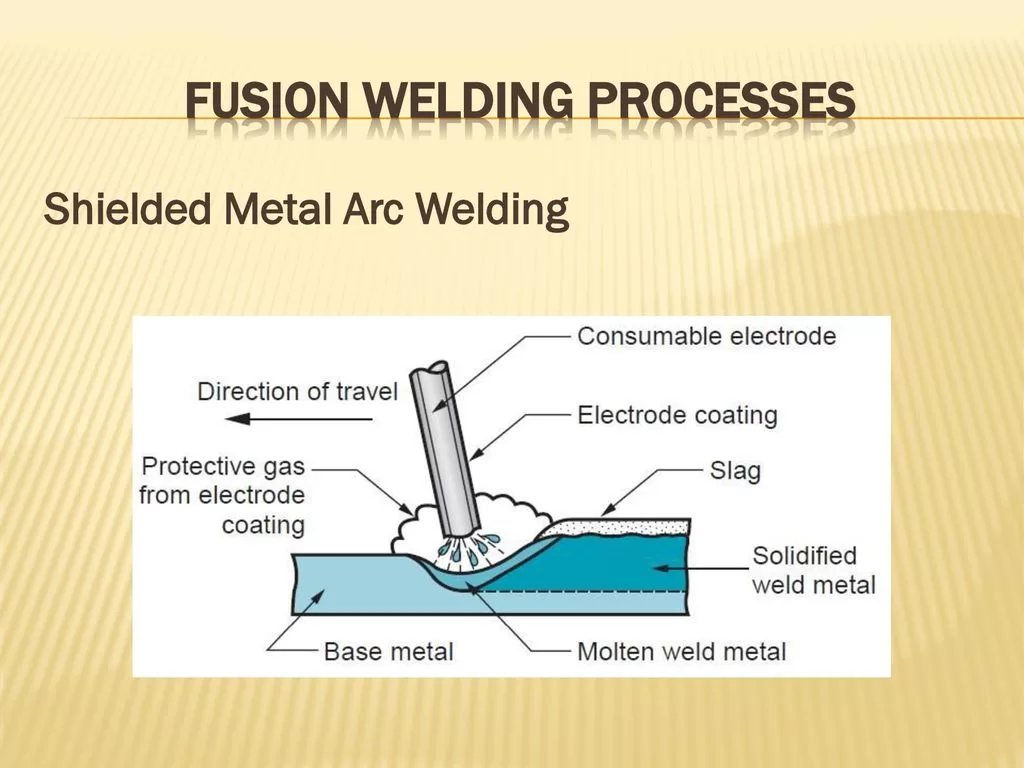

TIG welding, or tungsten inert gas welding, is a versatile type of arc welding that uses tungsten electrodes and inert argon gas to create a weld pool. It’s suitable for stainless steel because TIG welding machines produce precise, clean welds. However, and this is the main reason for writing this article, TIG welding also requires a lot of skill and practice, as well as proper equipment and settings. So far, the Tooliom TL-200T has been recommended as an ideal partner for pro TIG welders, especially when the workpiece is made of stainless steel. The Tooliom TL-200M is also available, and it adds MIG (Metal Inert Gas) welding capabilities into the mix.

TIG welding or tungsten inert gas welding is a versatile type of arc welding that uses a tungsten electrode and inert argon gas to form a weld pool. It is suitable for stainless steel because TIG welding machines produce precise, clean welds. However, and this is the main reason for writing this article, TIG welding also requires a great deal of skill and practice, as well as proper equipment and setup. So far, the TIG-200P has been recommended as the ideal partner for professional TIG welders, especially when the workpiece is made of stainless steel.

Regardless of which machine the welder chooses, there are a few other things that need to be taken care of before starting the arc. As mentioned earlier, the workpiece needs to be prepared. Select, clean and sharpen the proper tungsten electrode. Is the arc circuit set up correctly? A professional welder will check this by adjusting the current and voltage, followed by a quick check that the grounding clamp is tight. Finally, argon gas flows around the weld pool as set by the regulator. The welder is protected by wearing gloves and a welding helmet, as well as any other flame-retardant clothing.

At this point, there are a lot of things to manage. Controls, gas regulators, arc consistency and melt pool size, all need to be carefully monitored. One way to simplify things slightly is to add a foot pedal. Machine presets are also available from the machine control panel, but they need to be fine-tuned on-the-fly as the electrode’s travel speed across the weld changes.

Once the DCEN (DC Negative) setting is correctly locked, the cables are connected in the correct configuration, all safety measures are in place, and work can begin.

Managing The In-Action TIG Welding Process

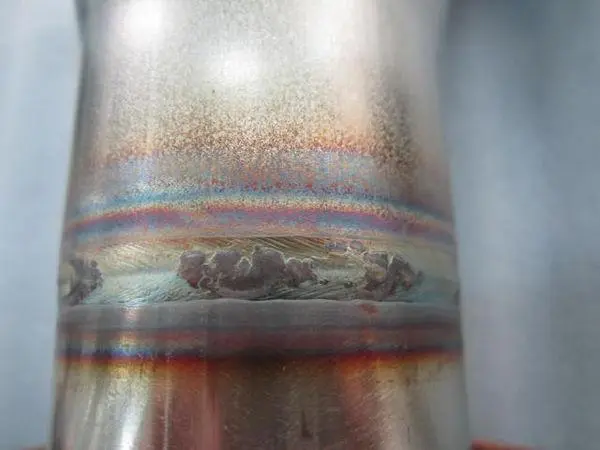

The goal now is to lay a clean, spatter-free joint. The melting process should be deep to the root, the electrode should move quickly, and the surface appearance of the weld should meet the requirements of the welding inspector. With no oxidation, little discoloration, and no workpiece warpage, the end result is clean and structurally sound.

There is no reason why these goals cannot be achieved. If the welder and preparation have been done correctly, the only remaining issue is the skill of the welder. This person must be well versed in the unique challenges encountered when using a TIG welder on a stainless steel project. Training is important here, as it has been experienced on past projects concerning this potentially difficult to weld alloy. Remember, stainless steel parts are common. They are especially common in structural work, engineering projects, and piping work. Austenitic stainless steels are popular. They are a class of alloys that can be welded, but their microcrystalline structure changes if exposed to a lot of heat.

Now, austenitic steels will absorb a lot of heat due to weld geometry issues and the corresponding reduction in travel speed. Professional welders should be aware of this problem. If the metal cannot dissipate this energy, it will deform. The alloy is rich in chromium, which is inherently corrosion-resistant, but if the weld temperature is too high, the trace element may be depleted. The problem of chromium depletion in stainless steel usually manifests itself as corrosion.

When it comes down to it, stainless steel parts have a very good insulation mechanism. And they cannot easily dissipate that heat. Corrosion problems, warping, chromium depletion and alloy embrittlement are all possible if the job is not done properly. Welding specialists can certainly solve these problems, but when other stainless steel families are added, this skill becomes increasingly difficult to master. Austenitic alloys are one such group, along with ferritic, duplex and martensitic steels. Unfortunately, this is a large number of graded stainless steels, all of which have their own mechanical and physical properties, all of which react in some way to large amounts of heat.

Solving Stainless Steel Weldability Complications

By maintaining travel speed, most problems can be solved immediately. There is no heat buildup and the small amount of heat present in the weld will dissipate without changing the microcrystalline structure of the alloy. Using the correct filler metal is also critical. If the grade of stainless steel is known, such as 316 austenitic stainless steel, a matching 316L filler will be selected. Similarly, this time a martensitic alloy is used, a stainless steel that contains more carbon. It is one of the most difficult alloys to weld and is prone to hydrogen cracking. Professional welders address these issues through the use of preheat work, matched filler and heat treatment.

Frankly, welders are not chemists and they should not understand the changes that occur when the microcrystalline structure of an austenitic or martensitic alloy is transformed in some unfavorable way. They do, however, have an intimate knowledge of welding equipment, which means they can regulate travel speeds and the amount of heat that remains in the HAZ (heat affected zone). As a result, the settings entered by the professionals will ensure satisfactory travel speeds, and they will also use the proper filler. All in all, when professionals work on stainless steel welding projects, it is absolutely possible to achieve a non-porous weld that goes down to the root.

Even though all these stainless steel welding factors may seem very complicated, there is a silver lining. Yes, professional welders are prioritized here, and top-notch welding machines such as the MIG/Stick/TIG Multi-Process Welder Trio are also prioritized, but there is also an element of common sense. Imagine a stainless steel job on some part of a large project that goes smoothly and without incident. There is a carbon steel plant nearby. There may be a temptation to share tools. Don’t do it. By sharing tools between two jobs, iron may be introduced into the stainless steel weldment, thus inserting a source of rust into an otherwise clean joint. It’s common sense, and it’s a powerful tool.

Beyond simple common sense, this requires careful and good work. There are too many grades of stainless steel to customize a weld setup plan for each grade. Instead, a professionally executed stainless steel work plan should be implemented. Be sure to maintain a well-regulated travel speed setting. Do the same for filler metal and shielding gas; keep matching filler on hand and always use 100% inert argon. A DC electrode negative arc is a must, along with the associated current and voltage settings, to achieve narrow, precisely applied weld path widths.

In short, don’t be intimidated by alloying problems. A powerful TIG welder can produce precise, clean welds as long as the welder is a professional and familiar with these unique challenges. Proper preparation is the first step, along with a judicious equipment setup program. Then it’s a matter of letting experience and training take over. If the training isn’t fully implemented, don’t blame the equipment. Instead, go back to the drawing board and practice, practice, practice.

It’s worth noting that since this article is coming to a close, implementing a good TIG training program will be easier, but replacing expensive stainless steel parts won’t be so easy if warpage or corrosion occurs due to substandard welding practices.

TIG welding stainless steel like a pro – FAQs

What are some application scenarios for stainless steel?

Stainless steel is used in the construction industry, pressure vessels and piping systems. In addition, its ductility and strength make it ideal for large construction projects that require a strong and durable support material.

What is the first step in mastering stainless steel TIG welding techniques and how do I do it?

Cleaning and preparation.

Remove grease, oil, corrosion and other contaminants from metal surfaces

Further preparation. Smooth the surface with wire brushes and abrasive tools

Choose the right inert gas. The heat affected zone of hot stainless steel oxidizes easily

Choose a good quality welder.

How to avoid some mistakes (pitfalls) for high quality results?

Use the correct diameter tungsten rod

Keep the tungsten electrode clean and sharp

Using 100% argon as a shielding gas

Manage application heat

Establishing a good, clean electrical ground

Use DCEN (Direct Current Negative)