If you’d like to MIG weld aluminum with your wire feed welder, this step-by-step tutorial will show you how…

MIG welder for Aluminium welding

Welding Town

If you haven’t yet mastered MIG welding mild steel, then you probably need to do that before you start aluminum welding with the GMAW (MIG) process.

Here’s why…

When MIG welding aluminum, you use the same gun angle and gas flow rate (20-30 CFH).

However, that’s pretty much where the similarities end.

MIG Welding Aluminum Basics

Aluminum is a tricky metal to weld with a MIG welder because it takes more heat than mild steel (Usually in the range of 21 to 24 volts).

The minimum aluminum thickness you should attempt is roughly 14 ga. To 18 ga. Any thinner than that and you’ll need a TIG welder.

With a TIG welder, you can actually weld a soda can together. Pretty cool.

Aluminum welding with a wire welder is notorious for having unexpected burn-through, and the weld puddle will literally fall right through the workpiece if you’re not moving fast enough.

That’s why you shouldn’t attempt to weld thin pieces of aluminum.

When you’re MIG welding mild steel, you can and should move the MIG gun slow enough to get deep penetration. Yet, with aluminum, the weld puddle resembles that of “wet foil”.

You won’t see a molten red hot weld puddle with aluminum. It takes time to get the feel for when the aluminum weld puddle gets too hot. That’s why you can easily destroy your workpiece if you’re not careful.

Travel Speed When MIG Welding Aluminum

A good rule of thumb is to use roughly the same voltage settings you would use with mild steel but double your travel speed.

Like I said before, you’re going to be moving uncomfortably fast at first with your MIG gun with aluminum until you get used to it.

MIG welding steel uses a short circuit transfer process, meaning that the wire electrode actually causes a short circuit at the joint, resulting in the molten weld puddle.

When MIG welding aluminum, you’re using spray transfer in most situations.

Spray transfer is a method where tiny particles of the aluminum wire are actually sprayed into the weld puddle. Most MIG welders will handle this process.

All you have to do is boost your voltage and use the correct gas mixture.

MIG Welding Aluminum Spool Gun

If you’re going to MIG weld aluminum with your wire feed welder, you’re going to need a spool gun.

Why can’t you just put a roll of aluminum wire in your MIG machine?

Because MIG aluminum wire is much softer than steel and tends to bird nest inside your cable liner. The wire isn’t as stiff as mild steel wire, so you have to compensate for that by using a spool gun.

Spool guns are good for DIY welders, and you can typically only fit a small 1 lb. roll inside.

The benefit of having a spool gun is that the aluminum wire doesn’t have to travel through the MIG hose, where it will likely get ratted up.

MIG Welding Aluminum Gas Mixture

When welding mild steel, you typically use what’s called C25 gas (25% CO2 and 75% argon).

For aluminum MIG welding, you would use pure argon shielding gas.

This will allow the spray transfer process to occur.

For thicker aluminum (1/2” or more), anywhere from 25% to 75% helium is added.

This allows for deeper penetration into the workpiece.

Polarity For Aluminum MIG Welding

MIG welding aluminum requires you set your machine on DCEP (Direct Current Electrode Positive).

With this polarity setting (known as reverse polarity), the electrons are traveling from the machine through the ground cable, and back in through the gun.

It’s important that you get this set right or your welds won’t come out.

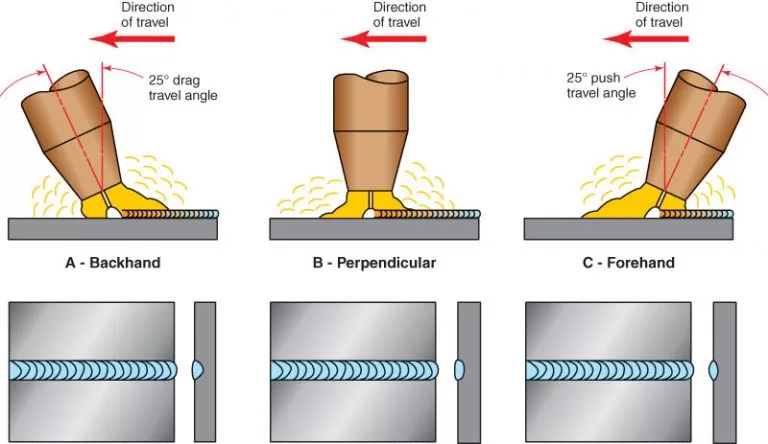

Should You Push or Pull?

When aluminum welding with a MIG you should always use the forehand (push) welding direction.

This ensures that the shielding gas covers the weld puddle sufficiently.

Here’s a handy image to illustrate this”

Pushing gives a flatter, wider bead with less penetration while dragging gives deeper penetration and a narrower bead.

You can do a test to see what I’m talking about.

When you try to pull the weld puddle with aluminum welding, you’ll notice your welds come out dirty. This is due to not leading the puddle with gas coverage.

With the push direction, you know you’re getting good gas coverage.

Oxide Removal

It’s essential (VERY important) that you remove the oxide from the aluminum before welding it.

Here’s why…

The oxide has twice the melting temperature of the aluminum itself and if you don’t remove it, your joints won’t fuse together.

It’s easy to clean your workpiece prior to welding it. You’ll want to get an aluminum wire brush (not steel because that will contaminate the weld).

Brush down the aluminum joint where the weld will be made, and you should be good to go.

Typically when MIG welding mild steel, you would maintain a shorter wire stickout (1/4”). Wire stickout refers to the amount of wire that extends beyond the MIG nozzle when welding.

For aluminum, since it uses the spray transfer method and gets much hotter, you need to use a longer wire stickout. Anywhere from ¾” to 1” stickout is good.