Porosity is a weld discontinuity that is not as detrimental to structural integrity as cracks, undercut, overlap and lack of fusion. However, it is unsightly and when painted it becomes an eye sore. Because it does not have sharp ends, porosity does not propagate like a crack. The reason for limits to the amount of porosity per structural codes such as AWS D1.1 and D1.2 is because it decreases the effective area of a weld. Regardless of these limits, we should always strive for ZERO porosity.

7 Ways to Eliminate Porosity in Your Welds

Welding Town

Porosity can be hard to troubleshoot since there are so many possible causes. However, the vast majority of cases can be solved by doing one or a combination of the following troubleshooting steps:

Check your gas flow rate.

If using a process that involves shielding gas, make sure you are running the adequate flow for your application. In general, any wire process will usually require about 30 – 50cfh. There is more variance in GTAW due to the difference in cup sizes, but in general you want to be between 15-25cfh for this process.

Make sure you gas flow rate is not see too high.

High flow rates (above 60cfh) for wire processes can actually cause porosity. More flow is not always better. High flow rates cause turbulent flow of the shielding gas which may actually introduce air into the weld, the very thing we are trying to keep out. If you have to increase your flow rate past 60 to avoid porosity you may have other problems such as wind (from a fan or from an open bay door), reach issues or gas leaks in your gun assembly.

Check for gas leaks.

Make sure all connections are tight. Check for damaged hoses. A common, but hard to find leak, sometimes occurs by improperly seating the back end of the gun into the receiving bushing in the wire feeder. Make sure it is as far back as it will go. Also check the o-rings on the power pin (end of the gun that slides into the receiving bushing) for damage. Even a small nick on the o-ring can be enough to cause shielding gas leaks.

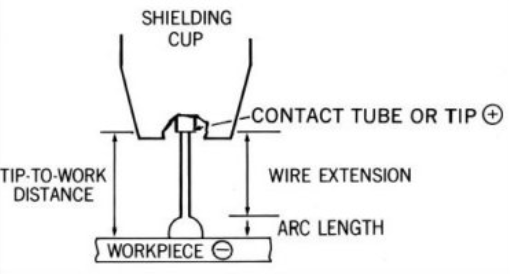

Keep an adequate contact-tip-to-work distance (CTTWD).

This is usually 3/8” to ½” for GMAW short-circuit transfer and 5/8” to 1” for GMAW spray. Excessive CTTWD will decrease gas coverage.

Welding Procedure Specifications should call out the required CTTWD. This is because it has an impact on amperage and penetration. If CTTWD is excessive it can also lead to porosity.

Avoid drafty conditions.

A draft caused by an open bay door or a fan can blow enough shielding gas away to create porosity. In fact, if you take a look at Clause 7.11 – Welding Environment – of AWS D1.1:D1.1M:2020 Structural Welding Code – Steel, you’ll find that it prohibits welding for the GMAW, GTAW, EGW and FCAW-G processes if the wind velocity in the vicinity of the weld exceed 5 miles per hour [8kph]. If you cannot stop the draft or need the fan due to the heat, position your body between the fan and the weld. This will also provide the added benefit of blowing the welding fumes away from your breathing zone.

Clean the surface to be welded.

Contaminants such as moisture, grease, oil, cutting fluids, rust, paint and other sources of hydrocarbons will significantly increase the susceptibility to porosity. Materials with a surface coating, such as galvanized steel will present a problem. It is recommended that you grind off the zinc coating before welding. However, in some cases you are not allowed to do so. In this case choose a process that is more forgiving for this application, such as SMAW (stick) or FCAW-SS (self-shielded flux-cored). For the GMAW process using an S-3 wire with a shielding gas mix with high CO2 content (such as C25 gas) can yield acceptable results.

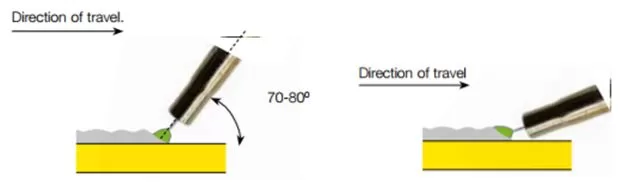

Watch your travel angle.

Keep it at 10-20 degrees from perpendicular (70-80 degrees from horizontal) whether you are pushing or pulling. Excessive push or pull angles will create problems such as porosity, lack of penetration and excessive spatter.

Whether you push or pull keep a 10-20 degree angle from perpendicular (or 70-80 degree from horizontal) as shown on the left. Excessive angles (as shown on the right) can create many problems including lack of penetration, spatter and porosity.

If you are welding on aluminum porosity is much more of a problem than when welding carbon steel or stainless. Everything that causes porosity on steel will have a greater effect on aluminum. Steel can tolerate higher levels of moisture, rust, paint, oils, etc. since carbon steel wires have deoxidizers that help reduce or eliminate porosity, aluminum wires do not.