You have a welding project you’re working on. It’s already tricky because the pieces you’re welding are aluminum. You love using flux-core wire for the convenience of not needing extra shielding gas, but you’re pretty sure the stuff you use on steel won’t work. So, you go hunting for flux-core aluminum welding wire. What do you find?

Nothing.

Well, that’s not quite true. You’re going to find a lot of options, but the deeper you look, the worse the situation will become.

First up, you find flux-cored aluminum wire, but it’s not for welding. It’s for brazing and soldering. Brazing and soldering are similar to welding, but they operate via thermal rather than electrical energy, and they’re a lot lower temperature than welding. If you tried to feed one of these wires through your welder, not only would the welder get all gummed up with crumpled wire, but you would incinerate the wire before you even got a glimpse of what a weld would look like.

Second, you find aluminum welding wires, some of which even advertise themselves as being flux-cored. Sounds ideal, right? Well, not quite. Unfortunately, all of these listings are either soldering or brazing wires as above, or they’re solid, not flux-cored. Solid aluminum welding wire exists, and is quite common, as are mislabeled eBay listings and storefront product pages.

So what’s the deal?

Flux-Cored Aluminum Welding Wire Doesn’t Exist

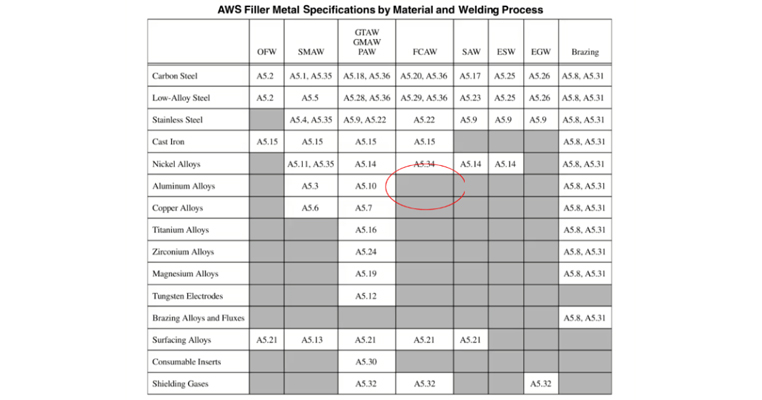

Here’s the American Welding Society’s spec sheet (source) for which wires exist for which processes and which specifications. Take a look at the column labeled FCAW (Flux-Core Arc Welding) and look for the row for aluminum. What do you see?

A grayed-out box with nothing in it.

It’s simply an incompatibility. Flux-cored wires exist for arc welding specific materials, like carbon steel, stainless steel, and cast iron, but they don’t exist for others, like titanium alloys, tungsten electrodes, or yes, aluminum alloys.

So, why is this? There are several reasons.

Aluminum is soft. Aluminum wire is already tricky to feed through a welding torch without it bunching up, crimping, bending, breaking, or otherwise becoming a huge hassle, and that’s for solid wire. Boring out the middle of the wire and filling it with an even softer, reactive flux material would make it like trying to feed a rubber hose; it would crumple, back up, and jam your machine every few seconds, forever.

Aluminum melts easily. One of the greatest challenges of welding aluminum is how quickly it melts and how much it’s prone to spatter; when you add a flux-cored wire to the mix with any weld, it increases spatter. At that point, you’re practically cutting rather than welding, because so much of your molten aluminum is just blown away that there’s hardly any left to fuse.

There’s also the issue of flux. Flux uses a chemical process to create a localized shield, while also drawing imperfections out of a weld pool to the surface where it can be brushed away later rather than impact the quality of the weld.

Fluxes work via the chemical properties of steel and iron. Well, as you very likely know, aluminum is not steel. Flux that works for steel doesn’t work for aluminum.

So, are there fluxes that work for aluminum? Yes… for soldering and brazing, which are much lower temperature than arc welding.

Arc welding fluxes have been developed in labs, but they are much less than ideal in real world usage.

- They’re extremely corrosive to the aluminum, meaning that each pass of the welding torch needs to be allowed to cool, be cleaned thoroughly, and be prepared for another pass.

- That same corrosiveness is also a huge health hazard for the welding operator using the welding torch.

- The fluxes are also very hygroscopic. That means they absorb moisture from the air, and as we all know, moisture is the enemy of a solid weld. Not only is it a problem in welding, it’s a problem in storage; improperly-stored wire would have so much moisture absorbed into it that your welds will be porous like a sponge.

- The chemicals necessary for the flux are terrible for the environment. We’re talking “your shop is a superfund site when you retire” levels of terrible.

So they’re hugely hazardous to the operator and the environment, they result in terrible quality welds, and they have a shelf life measured in microseconds when there’s any humidity at all in the environment. In other words, they’re simply untenable as a product.

Will Flux-Cored Aluminum Welding Wire Ever Exist?

Never say never. Materials science is constantly evolving, and our understanding of the underpinnings of physics make it certainly a possibility that one day, a flux can be found for aluminum that eliminates the problems listed above.

There are just two problems.

First, it hasn’t happened yet. As of right now, there’s really no such thing as a flux-cored aluminum wire meant for arc welding. So, don’t get your hopes up; even if one is developed, it will be years of testing before it can be verified as usable, and more years of manufacture before it can be produced and available at price points that make it feasible.

Second, it just isn’t a priority. There are perfectly acceptable ways to weld aluminum already available, so there’s no real push to make a flux-cored wire for aluminum arc welding as anything more than a curiosity at this point. It doesn’t really have enough immediate, tangible advantages to be a significant push in scientific development.

Without Flux-Cored Aluminum Wire, What Are Your Options?

So, there’s no such thing as a viable flux-cored aluminum welding wire. What options do you have?

Well, before you make a mistake and damage a workpiece, no, you can’t just use regular old flux-cored wire on the problem. A steel wire with a flux core is perfectly fine and as safe as any flux-cored wire… for welding steel.

“You may burn out your welder. The Amps needed to weld aluminum is more than a basic 90 Amp or 130 Amp welder can generate. The splatter produced would be mind-blowing. It would clog up your contact tip and could even short out your welder. And after that, you’d have no weld or one that failed. No point trying that one.” – Weld It Myself

There’s a reason you need to match the wire with the workpiece, after all.

If you have to join aluminum workpieces, there are some options, with their own pros and cons.

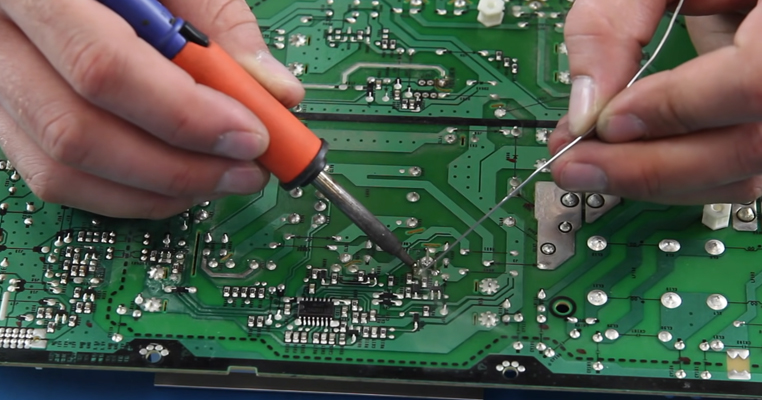

Soldering the Aluminum

Soldering uses an aluminum solder and a soldering iron. The iron melts the solder, which is softer and has a lower melting point than the aluminum. The solder can create a joint, and is most commonly used for small applications that are not structural; that is, connections in electrical components, not structural joints in a larger project.

It can be used to help seal up things like pipes as well, but brazing is more common for that application.

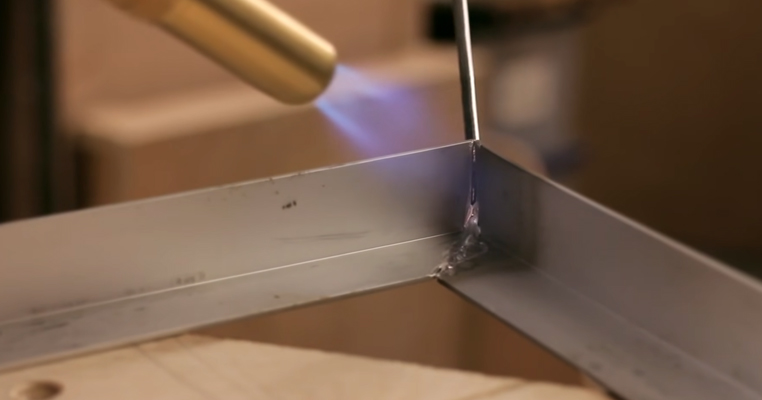

Brazing the Aluminum

Brazing uses a flame torch to heat and melt a flux-cored aluminum brazing wire. The flux forces impurities out of the wire, and melts the wire into a joint, like the gap between pipes. The base materials aren’t melted, however; it’s more of a sealant than it is a joint.

Brazing is a perfectly fine process, just like soldering; it just isn’t equivalent to welding. Arc welding is a different kind of process fundamentally, because it melts the base workpiece into a joint, rather than using a filler material exclusively as the joining material.

MIG Welding with Shielding Gas

MIG, or Metal Inert Gas welding, is a process where you use an electrical arc to melt a workpiece and a filler rod, creating a weld pool that solidifies into one finished joint.

MIG can be performed on aluminum just as well as it can be performed on mild steel or stainless steel. There are just two important details.

The first is that your wire will need to be solid-cored aluminum. As mentioned extensively above, there’s no such thing as a flux-cored aluminum wire for arc welding. If you tried to use a flux-cored brazing wire, it would vaporize, and the spatter would not just ruin your project, it could ruin your welding torch as well.

The second is that, since aluminum is so incredibly reactive to moisture and oxygen, you need a shielding gas. MIG welding aluminum is going to use 100% argon every time. And yes, argon can be expensive as a consumable, and yes, you absolutely need it.

TIG Welding with Shielding Gas

TIG welding, or Tungsten Inert Gas welding, is a process where you use an electrical arc to melt a workpiece and a filler rod, creating a weld pool that solidifies into one finished product.

Sounds familiar, right? The difference is the electrode and the current. MIG uses DC and feeds the filler rod through it as the electrode. TIG uses AC and a non-consumable tungsten electrode, and a filler rod melted into the weld pool from the other hand. Like MIG, TIG still uses a shielding gas. Also like MIG, using TIG on aluminum requires the use of 100% argon as that shielding gas.

TIG welding is harder to perform and harder to master than MIG; however, a well-done TIG weld is arguably stronger and definitely more aesthetically pleasant than a MIG weld. There will be less spatter, less distortion, and less irregularity in the surface… as long as the operator knows what they’re doing.

MIG, on the other hand, is easier for less experienced weld operators to handle without damaging a project. TIG has the potential to burn through, distort, or wreck a weld very easily; MIG is more forgiving, while also being faster and easier to handle for most welders.

Reading Up on Your Skill Level and the Project’s Demands

Don’t overlook the importance of your own skill level and the project specifics when picking between the gamut of welding methods for aluminum. MIG and TIG each bring something to the table, but how well you leverage their capabilities might hinge on your hands-on experience and project details.

Let’s say you’re tackling something intricate that calls for laser-focused precision. In this scenario, TIG could be your best bet, offering the exactness you’re after. But beware—if you’re not well-versed in TIG, you might be signing up for a steep learning curve that could mean mistakes, wasted material, and a project that drags on longer than you’d like.

In contrast, MIG is often the go-to for welders on the less experienced side of the spectrum or those whose projects don’t demand the finickiness of TIG. MIG is more forgiving and can fast-track your work. But speed isn’t everything, and MIG isn’t a one-size-fits-all solution.

Let’s say you’re working on a large-scale structural gig; MIG could be your winner here, hands down, especially for its ability to dive deep and get the job done fast. But flip the script—you’re working on a custom car or a piece of metal art where the visual appeal is king. Here, the nuance and control of TIG could pay off, even though it’s a bit of a time-eater and demands a skilled hand.

So, when you’re laying out your options, don’t just scrutinize the spec sheets and capabilities of each welding method. Also, factor in your own expertise, project complexity, and what you’re gunning for as the final product. This 360-degree view will set you up for a welding win.

What’s the Best Option?

When it comes right down to it, there aren’t a whole lot of different ways to join aluminum.

- Soldering isn’t structural and won’t provide a strong joint.

- Brazing also isn’t structural, and while it can make a solid seal on pipes, it’s not for strength.

- MIG is fast, relatively cheap, and relatively high quality while being easiest for intermediate operators.

- TIG is powerful, flexible, and beautiful, but requires a lot more skill to perform.

- Laser welding is possible, though having the equipment on hand is relatively rare and costly, so it’s a specialty service.

- Friction stir welding is a relatively new process that can provide excellent results, but only in a few specific kinds of situations.

- Riveting is another way of creating a strong joint, though it’s not a solid joint the way a weld will be.

Overall, your best option is almost always going to be MIG, unless you have a good reason to pick something else. Similarly, with aluminum, you’re going to want to go with argon as your shielding gas, for the best possible results with the least potential contamination. Even then, you need to make sure your aluminum is as clean as possible before you begin.