To complete your projects, you’ll need a welding tank of an appropriate size. Selecting the best welding gas tank size for different applications can be a confusing task for many people.

The Best Welding Gas Tank Size

Welding Town

Sounds tricky? Don’t worry, you’ll learn everything you need to make an informed decision in this comprehensive guide. I have also found the best-value full gas cylinders in 3 different sizes for Argon, and C25, to own outright.

In this article you’ll find some tips and tricks to getting what you need.

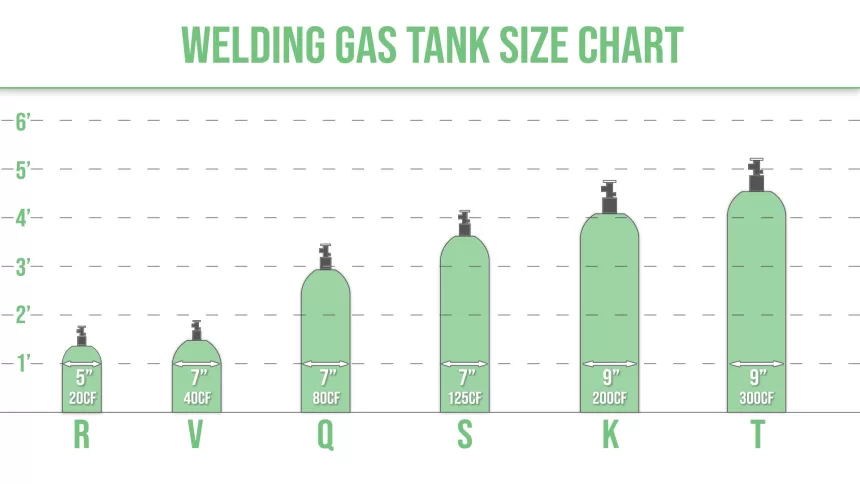

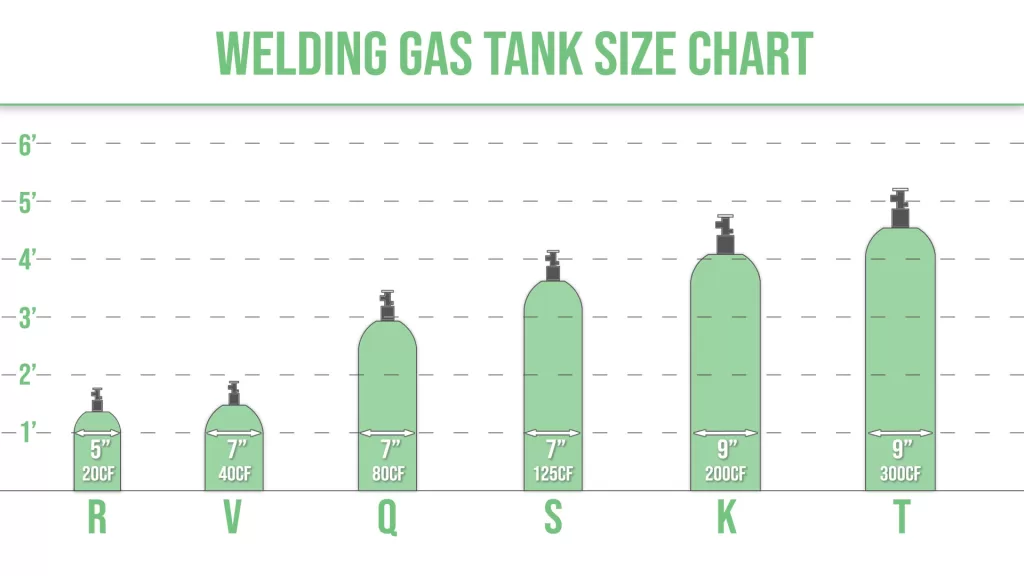

What Argon Tank Sizes Are There?

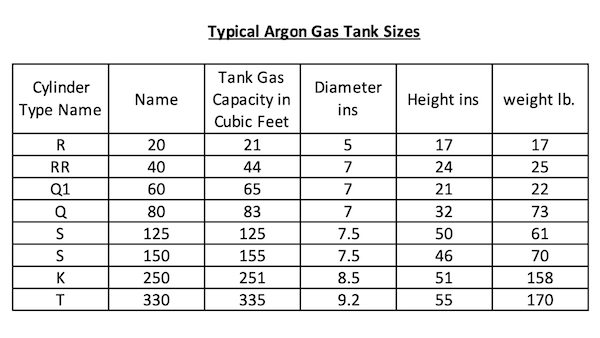

Here are the Widely Available Argon tank sizes. And how much Argon gas they typically hold.

- Tank Size R. Also called a 20. Holds 21cf

- Tank Size RR. Also called a 40. Holds 44cf

- Tank Size Q1. Also called a 60. Holds 65cf

- Tank Size Q. Also called an 80. Holds 83cf

- Tank Size S. Also called a 125. Holds 125cf

- Tank Size S. Also called a 155. Holds 155cf

- Tank Size K. Also called a 251. Holds 251cf

- Tank Size T. Also called a 335. Holds 335cf

What’s The Difference Between Argon Tanks, Cylinders And Gas Bottles?

Argon tanks are also known as cylinders or gas bottles.

From the table below you can see the sizes of Argon tanks vary from small and portable to large and weighty. You measure the gas inside an Argon gas cylinder in cubic feet (you’ll see it also written as cf).

Each high pressure cylinder can last a long time.

You can use a tank that’s tens of years old. If it’s kept well. Is within its testing dates and stored with care.

What Are The Most Common Argon Cylinder Sizes And Volumes?

Argon Tank Sizes Chart

Here’s a chart showing the cylinder type names in the first column. The second column shows the common name for that tank size.

In the third column you’ll see the amount of Argon gas in cubic feet for that size of tank.

The 4th and 5th column details each tank size diameter and height.

And the last column tells you the approximate weight for each tank size.

All the sizes shown above are estimates and averages.

Even so this table will give you a good starting point for the more common welding gas cylinder sizes. And an idea of the amount of Argon gas a cylinder of that size should have in it.

Argon Tank Cylinder Size Name Versus Its Common Name

Why are there two names?

It’s a quirk of the compressed gas industry.

An example of this is. There are some distributors that call a 40 cubic foot tank a 40.

Others call the same Argon tank size an RR.

You’ll find it’s worth your while being familiar with both names.

You can use the chart to guide you.

And compare it to what you hear high pressure tanks called in your area.

Why Are There Two Different S Size Argon Cylinders On The Chart?

It’s not a mistake.

You’ll find out there in the market that there are two different sizes of ‘S’ size tanks.

Depending on your gas supplier and where you are in the country. Your S tank could hold 125 cubic feet of gas. Or 150 cubic feet of gas.

It’s worth you double checking.

Why Do Argon Bottle Sizes Vary?

If you’ve checked around looking to buy or rent an Argon gas tank you’ll have noticed something.

Compressed gas cylinder sizes can differ. Because tank makers manufacturer gas bottles in slightly different sizes and weights.

Why?

Because it’s then easier for gas distributors, suppliers and rental companies. They can quickly spot their tanks.

Argon compressed gas cylinders disappear off the backs of trucks. And from company storage cages and turn up on the second user market.

So when those tanks next go in for a refill. Gas suppliers recognize stolen tanks and return them to their rightful owner.

Beware. And understand how to spot a stolen tank so you’re not caught out.

MIG/TIG Welding Gas Tank Specifications – Argon and MIG blends

The table below shows specifications for TIG welding and MIG welding gas blends. It will help you get an even better understanding of the gas tank size you need. The size of the cylinder is also indicated by a lettering system that is often used to mark the cylinders.

| Size | 40 cf (#2/V) | 80 cf (#3/Q) | 125 cf (#4/D) |

|---|---|---|---|

| Height | 22 in. | 35 in. | 45 in. |

| Diameter | 6½ – 7¼ in. | 6½ – 7¼ in. | 6½ – 7¼ in. |

| Empty Weight | 24 lbs | 47 lbs | 58 lbs |

| Full Weight | 28 lbs | 56 lbs | 71 lbs |

| Full Pressure | 2015 PSI | 2015 PSI | 2265 PSI |

All of the presented sizes and weights are approximate. You should see exact details with the supplier.

If you are unsure if the gas cylinder size you are interested in can fit safely in the storage area, double-check everything. Your welding cart also needs to support the cylinder sizes you want to get. So don’t overload the cart. If the cylinders can’t fit then get a bigger cart.

A handy tip is to call the gas supplier company in your area and see what size they recommend. They have a lot of experience with the gas supply mechanisms, your area’s climate, storage regulations and other important pieces of information. This can help you in deciding your gas tank size.

Isn’t There A Standard For Argon Gas Cylinder Sizes?

You’ll find the truth is … not really.

The common Argon gas cylinder sizes are the ones listed in the chart.

But the trick manufacturers use is to make uncommon Argon gas bottle sizes.

So that they can easily know which are their rental tanks. And get back their stolen ones.

What Color Are Argon Tanks? There Are A Few Standard Sizes But Are They Standard Colors?

Hmmm …. again the truth is no there isn’t.

Don’t you be the one taken in by the color of the tank. And think you know what’s inside.

Because each manufacturer decides what welding gas cylinder colors they’ll use for their tanks. It’s another way of quickly spotting their high pressure gas tanks.

The only way to know what’s inside the compressed gas bottle is to read its data label. That’ll tell you what’s inside the tank.

If you can’t find the tank’s data label. Or it’s missing pass it by.

Because who knows what’s inside that tank?

And you’ll be the one in for a nasty surprise.

It could hold highly flammable gas. Or poisonous gas. Who knows!

And you won’t get your gas bottle refilled without one.

What Size Argon Tank Will You Need For Your MIG Welding?

Here’s a chart for you showing Argon bottle sizes along side weld time.

Argon Cylinder Sizes And MIG Welding Time Chart

| Tanks Size Name and Gas Volume | Estimate of Welding Time |

|---|---|

| R – 20 cf | 1 – 1.5 hours |

| RR – 40 cf | 2 – 2.5 hours |

| Q1 – 60 cf | 3 – 4 hours |

| Q – 80 cf | 4 – 5 hours |

| S – 125 cf | 6.5 – 8 hours |

| S – 150 cf | 7.5 – 10 hours |

| K – 250 cf | 12.5 – 16.5 hours |

| T – 330 cf | 16.5 – 22 hours |

How Long Should A Bottle of Argon Shielding Gas Last When You’re Welding?

You’ll find estimated gas flow figures in the above chart.

You’ll find these estimates based on Argon gas shielding coverage. When you run at the usual 15 to 20 cubic feet per hour.

Why are these rough estimates of MIG welding time?

Because when you’re welding in the real world. Many things affect how you personally use your gas welding.

1. When you weld you’ve the pre-flow and post gas flow use of Argon gas.

And that means you’re using up Argon gas outside of your actual welding.

2. Do you do lots of tack welds and short bead lengths?

Then you’ll probably run through your shielding bottle of Argon gas sooner. Increasing the cubic feet per hour of gas you use. Because you’ll have more pre-flow and post flow of Argon gas.

3. When you’re learning to weld, you’ll run through Argon gas quickly.

And that’s because you’ll get things wrong. Try again. And eventually find the settings you want for your high pressure gas.

What Size Of Argon Gas Cylinder Do You Need?

The answer depends on whether you’re an experienced welder. And so you’re welding longer beads. Or you’re a newbie. And you’re MIG welding for the first time.

The right answer depends on what your welding?

And so which Argon based high pressure gas you buy.

You’ll Need 100% Argon for MIG or TIG Welding Aluminum

For sure when you’re new to MIG welding Aluminum. You’ll be better off buying or renting an Argon tank larger than you first thought of.

But what if you can’t afford it?

Sure, pure Argon gas is pricey. And when you’ve a tight budget you’re tempted to go with a smaller tank.

But it’s a real pain, breaking off your welding mid project to get more Argon gas.

And takes up your time.

And when your TIG welding and new to the game you’ll use up even more of your shielding gas.

Budget well and remember Argon gas doesn’t go off.

MIG Welding With A High Argon Carbon Dioxide Mix

And the handy thing is that Argon CO2 uses the same type of gas cylinders. And gas valves as pure Argon.

So, the information you have in this article is just as relevant.

You’ll find 75% or above Argon gas. With the rest of your gas mix CO2 is cheaper to buy than pure Argon.

Because the cost of your compressed gas rises with the percentage of Argon in the mix.

Experienced or newbie. You’ll find it’s good advice to get the biggest welding gas cylinder you can get away with.

Decide on a 125 cf (cubic foot) Argon tank. Or even a 150 cf tank. Because of the cheaper cost per cubic foot when you refill.

And remember your Argon Carbon Dioxide gas mix, just like pure Argon gas won’t go off.

Want to find out more about 75/25 Argon CO2 tank sizes for Mild Steel welding. Then click the link text to hop on over to a document all about it.

Make sure you close your gas valves. And your Argon CO2 will be there waiting for you when you next want to use it.

Argon Tank Size Versus How Often You Weld?

You’ll find advice out there saying go for the smaller Argon gas tank sizes if you don’t weld much. And this is good advice when you’re renting your Argon tank.

Because you pay rental costs as long as you have the tank.

But if you’re buying your own Argon Tank. You’d be better getting the largest Argon tank size you have space to store.

Because larger Argon gas tank sizes are more cost effective to buy and refill.

And of course Argon gas doesn’t go bad.

Take some time to work out the price of a larger Argon tank compared to a smaller tank.

And think about how many smaller cylinders you’ll need to refill before you cover the cost of a larger one.

Then factor in the cost of getting your smaller Argon Tank refilled. And travel time and petrol used by your truck. Particularly if you live some way away from where you get your Argon tank refilled.

TIG Versus MIG Welding And How Does That Affect The Argon Tank Size You Pick?

For sure you’ll use more Argon gas TIG welding Aluminum.

Because TIG welding is a slower more precise process compared to MIG welding.

So if you’re TIG welding Aluminum. Consider buying or renting an Argon Tank a size up because you’ll be using more gas.

Welding Tank Sizes And Transporting Your Argon Gas Bottle Around

Do you weld away from your workshop? And does that mean you’ll need to take your MIG welder and an Argon gas cylinder with you?

Then for you a smaller Argon tank size makes sense.

But you then accept the increased cost per cubic foot of gas for the easy lift and shift size of your Argon tank.

You’ll benefit in having 2 Argon welding tanks the same size.

Because you’ll run out of Argon gas quicker using smaller tanks. So if one goes empty you don’t have to stop mid project to run out and get it refilled.

And you don’t have to worry about how much Argon gas you’ve left in your tank.

And if you have enough to finish your project.

You simply carry on welding till you empty your Argon gas bottle, then swap over.

And if you find you’ve to wait a few days for your local welding suppliers to fill your owned bottle for you.

You’ve another bottle and you can carry right on welding your project till your other tank is ready to pick up.

Some Other Things For You To Think About When Picking Your Argon Bottle Size

1. How Far Do You Live Away From Your Argon Gas Supplier?

Think this is obvious?

But the truth is.

The further away you live from your local Argon gas supplier. The more it costs you in time. And fuel for your truck to get there.

And you’re better off getting yourself one of the large Argon gas cylinders. So you’ll make fewer trips to get refills.

2. How Many Argon Gas Suppliers Do You Have Locally?

It’s worth your while checking around for prices.

Argon gas prices can vary widely by supplier and by county. You could save yourself dollars and find yourself a good price competitive supplier.

3. Do You Have A local HVAC Gas Distributor?

A little trick to know is that you could get refills of Argon gas from them on the cheap.

4. Find Out What Argon Bottle Sizes You Can Rent

Or lease locally.

And under what conditions. And at what price.

5. Can You Get Your Compressed Gas Bottle Tested Locally?

If you decide to own your bottles you’ll need them safety tested at some point. What is the cost of the test? Availability and costs can vary.

6. What Can You Safely Transport?

Compressed gas bottles need transporting upright.

Compressed Argon gas tanks have a stop valve at the top. And it’s important that this valve is not knocked or damaged while you’re driving around.

You’ll see the valve protected with a collar. For your safety keep that collar on.

Secure your Argon gas cylinder with straps, chains.

You don’t want the cylinder bumped or tipped.

7. What Do You Have As Transport?

Truck? Car?

As this dictates the Argon bottle sizes you can drive around yourself.

8. What Can You lift?

Do you need to go up or down stairs to where you MIG weld? Take another look at the table on Argon tank sizes above. You’ll see that the large cylinders are heavy.

9. Can You shift Your Argon Tank Yourself?

Some suppliers are relaxed about the Argon bottle sizes you take for refill. As long as you can shift it yourself.

10. Cost Of Delivery?

If you can’t lift it or transport it yourself you’re gonna need your Argon gas bottle delivered. Find out from your gas supplier how much that’s going to cost you.

Moving Your Argon Compressed Gas Bottle

When moving your high pressure Argon tank use gloves, safety glasses and steel toe capped shoes on your feet.

Your cylinder falling on your toe or foot will earn you a trip to the emergency room.

Safe At Home Storage Of Your Argon Cylinder

Your Argon gas cylinder needs storing somewhere cool out of direct sunlight.

Somewhere dry to stop any rusting of your gas cylinder.

And store your Argon tank upright.

Take off your regulator when you’re not using your Argon gas tank.

Close fully the cylinder valve and put on the safety cap.

Look Often At Your Cylinder Valve For Any Damage, Wear And Tear

Check your cylinder for rust.

Secure your cylinder to a wall. Or running gear. Or other firm support with straps or chains. You really don’t want your Argon gas tank knocked over.

When Transporting And At Home Argon Cylinder Safety

Argon is an inert gas. It can and does displace oxygen in the air you breathe.

And Argon gas escaping in an enclosed space can suffocate.

It’s something worth thinking about when you move your Argon gas around.

You’ll find it’s best not to transport your Argon gas cylinder in an enclosed car.

And when welding in your home garage get yourself plenty of ventilation.

Why?

Well, here’s a little story for you

Argon gas is used for the industrial and humane slaughter of birds. Because it’s colorless, odorless and tasteless and quickly causes suffocation.

Don’t you be a chicken.

Transport, store and use your Argon gas with plenty of ventilation.

What To Do Next

Now you know what Argon tank sizes there are.

And what to think about when you choose the size of Argon gas tank for your welding.

How about checking out some of the other articles on the site about shielding gas.