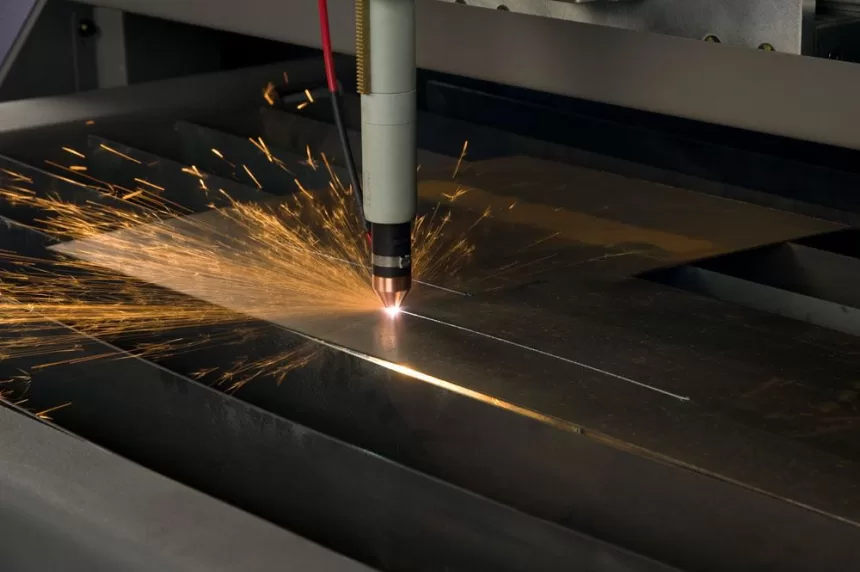

If you discuss metal cutting, you will come across some standard treatments. It can be a mechanical cutting method or a thermal cutting process. Plasma cutting falls under the latter category, which is the thermal cutting process; in this process, an ionised gas is used to cut the metal.

7 pros and common problems for Plasma Cutter

Welding Town

Plasma cutting is a recognised technique that can help in cutting thick metal sheets. They can also be used to cut thin metals. Before talking about the benefits and problems they offer, let us understand the concept. Plasma cutting services are booming for many reasons.

Meaning Of Plasma

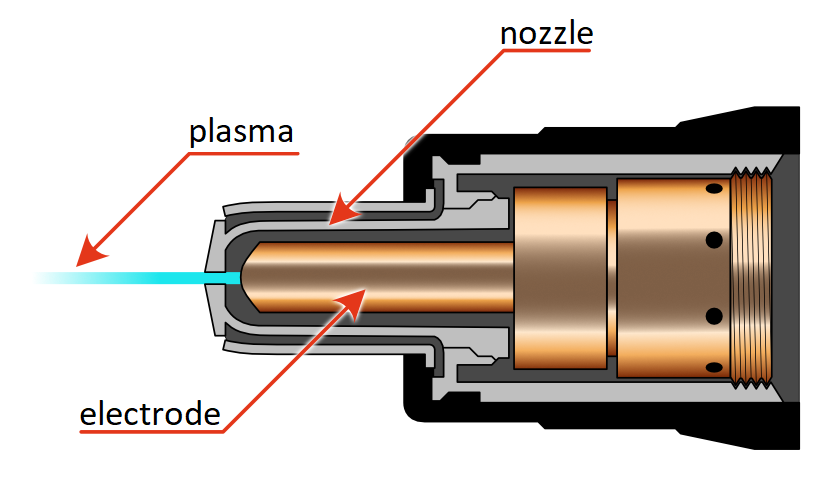

You may have heard this terminology when studying states of matter. Usually, students are taught that matter exists in three states. But plasma is the fourth state. Plasma is an ionised gas-like substance with the ability to conduct electricity. This means that in plasma, some atoms lose electrons while others can float around.

When a gas is intensely heated, it can be converted into plasma. Therefore, you can call plasma an ionised gas. Its behaviour is similar to that of a liquid because they can flow when exposed to magnetic fields and electron currents.

Its use in everyday life is so remarkable that you can recognise it from devices such as televisions. Fluorescent lights, neon lights and plasma cutters are other ways in which plasma is used.

Working Of A Plasma Cutter

Here are some of the some of the disadvantages you need to know about:

- Not suitable for thick or dense metals

Most plasma cutters cannot cut thick or dense metals. A plasma cutter can usually only cut to a depth of about an inch. So, if you want to use it to cut huge blocks or steel columns, you’ll have to choose another option. You will need to use a traditional industrial sawing or melting process when making this type of cut.

In addition, plasma cutting restricts the heat in the environment. Moreover, the process is noisy and produces excessive smoke. If you choose to use a plasma cutter, you should make sure that the cutting process takes place in a properly ventilated open shop.

- Bright flash

Another thing you need to know is that a plasma cutter produces a bright flash of light during the cutting process. Therefore, if you choose to use it, you need to make sure that all employees who are near the cutter or using it are instructed about it and wear proper eye protection. - Expensive

Cost is a factor to consider when choosing a cutting machine. However, plasma cutters are not cost-effective.

People will persuade you to think that it is cheaper than oxygen fuel and therefore you should use it. However, you should note that you will still have to pay a high cost regardless. Electrodes are part of the process and are an expensive resource. And, if they need to be replaced, the price will rise further.

Benefits Of Plasma Cutters

Let’s move forward in a positive way and discuss the benefits that plasma cutters offer. Specifically the following:

- High portability

Plasma cutting offers excellent portability and can be scaled down to the point where it can be hand held. In addition, you can transfer the cutter between sites without any backlog or transport issues. In addition, new employees will have no problems learning to use the cutting gun. - Results as expected

Are you looking for precise cuts such as curves and odd shapes? A plasma cutter can help you achieve everything you want. Plasma guns can be guided and you can choose between manual or computer-assisted control. In addition, they offer fast and efficient cutting. You can expect results in a quarter of the time required by other techniques. - Versatility

The plasma cutting process is very flexible and can be used with a wide range of materials. This is entirely due to the cutter. You can cut metals such as copper and titanium, as well as iron, steel and many types of alloys. In addition, it is an energy efficient method with an oxygen cutting ratio of 1:2. the equipment is cost effective. In addition, the cutting lance used in the process does not require expensive maintenance and rarely needs to be replaced. Therefore, you have an advantage when choosing a plasma cutter. - Safer than other methods

During the cutting process, the cutter relies on inert gas, which is safer than oxygen-based cutting. Oxygen fuels carry a higher risk of explosion or accidental ignition. These problems can occur during storage or use. In addition, plasma cutting gas is converted into a superheated plasma jet while the gun is in process.

Conclusion

Plasma cutting machines are a high technology cutting method. These cutters are capable of achieving a clean cut every time. Moreover, the quality is unquestionable, offering optimum medium thickness at a reasonable price. However, only certain things are applicable to the users. Therefore, whenever you are choosing a cutting method, you need to consider two important factors: thickness and the application of the part to make the best decision.