Have you ever encountered the concept of fusion welding and been curious about its significance? Fusion welding, like many other welding techniques, serves the purpose of uniting two or more items through the application of heat. What sets this welding method apart is its inherent uniqueness – the option to employ filler materials or not, coupled with the absence of any need for external pressure. Provided that the two materials to be welded are composed of similar substances, the welding rig’s heat causes their surfaces to meld together, facilitating the fusion of these objects.

What are the Basic Types of Fusion Welds

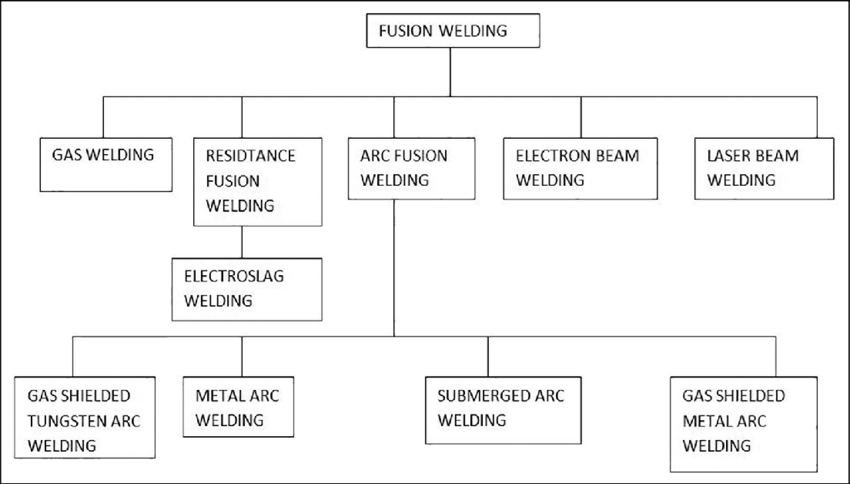

Understanding different types of fusion welding processes are critical when discussing fusion welding. Based on the heat source, fusion welding processes can be categorized as follows:

1. The Arc Welding Process

Arc welding is among the preferable ways of a fusion welding process. True to the hype, arc welding connects two parts (or more) using an electric arc. The reason is that electric arcs generate heat levels that reach up to 6,000 degrees Fahrenheit, making them ideal for fusing hard metals and materials. Additionally, arc welding is also suitable for offshore applications where you can perform underwater fusion welding. Commonly, arc welding processes include:

- Shielded Metal Arc Welding (SMAW): Commonly used for welding non-ferrous and ferrous materials in nearly all positions.

- Metal Gas Arc Welding: An electric arc is forming between the material and consumable wire electrode, allowing them to melt and fuse. Shielding gas is used to avoid airborne contaminants and oxidation for MIG welding.

- Tungsten Inert Gas Welding: Non-consumable tungsten is used in creating an arc between the basal plate and electrode. To avoid oxidation and atmospheric contaminations, an inert shielding gas is used.

- Plasma Arc Welding (PAW): In this arc, an electric arc is formed between the torch nozzle and electrode. The argon gas (plasma), usually in the chamber, is ionized by the electric arc.

- Submerged Arc Welding (SAW): It uses a continuously fed consumable electrode together with a flux. The flux prevents spatter and sparks and becomes conductive in a molten state, hence providing the current electrode and material path.

- Flux Cored Arc Welding (FCAW): The process is also continuously fed consumable electrodes with flux; hence it serves as an alternative to SMAW.

2. Laser Beam Welding (LBW)

As the name suggests, this is a fusion welding process that uses a focused laser beam as its energy heat source. The high heat levels have precision rates useful for joining metals and polymers. It is a fast and automated process that uses light to generate heat.

You can perform an LBW in the air instead of a vacuum, unlike the electron beam fusion welding processes.

3. High-Energy Welding Processes

It is a fusion welding process that produces heat through light radiation. To fuse the different materials, you blast the radiation light to the materials’ surface, making them become hot and start to melt. The workpiece will later merge as they gradually cool down.

These are typical examples of high-energy fusion welding processes.

4. Electronic Beam Welding (EBW)

The electronic beam welding process involves high-velocity electrons to join workpieces together. The electrons produce intense heat that enters the materials changing their solid-state to molten. EBW welds are deep and thin and can only be achieved under specific atmospheric conditions.

5. Friction Welding

When applying the friction welding technique, the different materials are joined together using mechanical friction. There are various ways to perform mechanical friction on aluminum, steel, and sometimes wood materials.

The process of mechanical friction is arduous. However, the heat you generate will soften both materials, creating a bond after mixing and cooling afterward.

There are various ways to perform friction welding, which determines the kind of joints you will have. These processes include:

- Friction stir welding

- Rotary friction welding

- Friction stir spot welding

- Linear friction welding

When applying friction welding, there is no need for shielding gas, flux, or filler metals. The process is ideal for applications that are considered lightweight and for non-weldable materials like some forms of aluminum alloys.

6. Resistance Welding Processes

It is among the fastest fusion welding options you can apply, making it a preferable choice for the automotive industry. Today, there is two resistance welding process. These are:

Resistance spot welding

It works by producing heat on two electrodes. However, the bonding process depends on the properties and thickness of the materials. The process confines the welding voltage to a single spot when fusing the different workpieces.

Resistance seam welding

It is a form of spot welding that includes a sequence of joint-alternating nuggets. It uses shifting disks to replace the spot welding electrodes to join the materials together.

How Fusion Welding Works

Fusion welding, as the term suggests, operates by uniting the edges of diverse materials through the application of heat, raising them to a point of liquefaction. When creating a joint, a filler material may be required to bridge any gaps present. This heating process introduces numerous phase transitions, as it generates a region known as the heat-affected zone (HAZ) within the material(s).

The process of fusion welding unfolds when the molten base materials blend with the molten fillers. The source of heat, responsible for the materials’ transformation, can either be concentrated within the joining zone or externally generated at the designated welding juncture. For instance, you have the option to pass an electrical current through an electrical contact resistance between the edges of the materials you intend to weld, thereby generating the necessary heat.

Distinguishing Fusion Welding from Non-Fusion Welding

In contrast to fusion welding, non-fusion welding does not necessitate heating materials to the point of melting. It can transpire with relatively low heat intensity, as it avoids the liquefaction of the parent materials. Furthermore, non-fusion welding operates without the need for filler materials. Common examples of non-fusion welding methods encompass soldering, brazing, and pressure welding.

Read More:What is Heterogeneous Welding? – Examples, Its types, Pros & Cons

Where is Fusion Welding Used?

In the contemporary world, fusion welding finds a multitude of applications, contributing to the construction of colossal structures such as ships, airplanes, welded pipes, bridges, automobiles, and pressure vessels. Moreover, fusion welding plays a pivotal role in sealing explosives, among other diverse functions.

One of the standout features of fusion welding lies in its utilization of a robust heat source, enabling the seamless fusion of even thick workpiece sections. The primary applications of fusion welding encompass:

- Metal Fusion The key distinction between fusion welding and techniques like soldering or brazing lies in the high-temperature process it employs. Unlike brazing and soldering, fusion welding involves the melting of the base metal, and at times, the inclusion of a filler material.

When different parent metals are exposed to elevated temperatures, they enter a molten state, effectively merging and forming a weld bead upon cooling. This can result in a joint that is notably stronger than the parent materials themselves.

In certain scenarios, the application of pressure can be combined with a heat source to create welds. When fusing metals, the introduction of shielding gas proves invaluable, preventing oxidation or contamination of the filler metals and the molten joint.

Uniting Polymers (Plastics) through Heat

When it comes to joining two or more plastic materials, heat plays an indispensable role, with the exception of solvent welding, which relies on adhesive agents. This amalgamation process unfolds in three essential phases:

- Surface Preparation: This initial step involves the meticulous cleaning and thorough drying of the surfaces to be joined.

- Application of Heat and Pressure: This marks the pivotal bonding stage, resulting in the complete coalescence of the materials.

- Cooling the Materials for Fusion: The extent of cooling required can vary depending on the specific parent materials involved. Nonetheless, due to the rapid cooling process, this phase is typically expedited.

In the realm of plastics joining, there exists the flexibility to employ either internal or external heating methods. It’s worth noting that polymers, in general, exhibit less strength compared to metals. As a result, the heat required for their fusion is relatively reduced.

Fusion Welding for Joining Wood Materials

Wood welding also uses heat that is generated from mechanical friction to join different materials. The materials are subjected to immense pressure followed by a linear friction movement to create the heat that bonds the workpieces firmly.

The process is fast and allows the joining of wood materials without using nails or adhesives within seconds. It is also a better way to preserve the wood design while strengthening the final workpiece.

Advantages of Fusion Welding

- Easy use of filler material when filling a large gap when joining different workpieces.

- The initial shape of the materials does not matter. Hence there is no need for external pressure.

- No need for edge preparation or design as they will affect the heat penetration.

- Fusion welding allows more than two-parent materials to be joined firmly together.

- The fusion welding process is fast and straightforward, making it the best solution for industrial use.

Disadvantages of Fusion Welding

- It is difficult to join metals with different melting points.

- Profound heat-affected zones (HAZ) are evident on welded components. HAZ is the weakest part of a welded workpiece.

- There are cases where the mechanical properties of the workpiece materials get compromised due to intensive heating. Such instances occur when using filler materials and different metals.

FAQs: What Is Fusion Welding?

How is fusion welding different from solid-state welding?

Solid-state welding requires close contact of two clean metal surfaces to form a metallic bond. The advantage of solid-phase welding over fusion welding is that you can achieve it in temperatures as low as room temperature.

The bonding process takes place either by deformation or limited deformation by diffusion. The diffusion (atomic movements) will make new bonds between the atoms of the two-parent materials.

What is electric arc welding?

Electric arc welding involves joining two or more different metals. The process can be achieved with or without filler material and external pressure application.

What are the basic principles of fusion welding?

Fusion welding primarily uses a heat source to generate sufficient heat necessary to maintain a molten pool. You can find various heat sources, including a gas flame or electricity. However, not all forms of fusion welding require heat. For instance, pressure welding can create permanent bonds at lower or room temperature.

What is a fusion welding zone?

A fusion zone is a section of the parent material that is left after the welding. A fusion zone is marked by the beginning and ends of the coalesced workpiece. All fusion zones possess a chemical composition of the mixed substrates you are welding together. In instances where you use a filler material or gas shielding, the fusion zone will have all these elements in its composition, making it different from the parent materials.

![12 Different Types of Welding Processes [The Definitive Guide] 6 12 Different Types of Welding Processes [The Definitive Guide]](https://www.021208.com/wp-content/uploads/2025/01/12-Different-Types-of-Welding-Processes-The-Definitive-Guide-150x150.jpg)