Flux-Core Vs. MIG Welding – The Similarities

Both MIG welding and flux-cored welding techniques are beginner-friendly and offer ease of learning and handling. One of their notable features is the continuous wire feed, where the wires themselves act as electrodes.

Is Flux Core Welding as Good as MIG Welding?

Welding Town

Furthermore, both MIG and flux-cored welding provide an automatic feed to the torch, resulting in a faster welding process that is continuous and uninterrupted. This feature makes them preferable for beginners compared to stick welding, which requires constant feeding of electrodes into the welding machine.

Another similarity between flux-cored and MIG welding is that while flux-cored welding exclusively uses flux-cored wires, MIG welding allows for the use of either solid MIG wire or flux-cored wire, providing versatility in welding options.

In terms of wire usage, both techniques are equally effective and enable welding in various positions.

MIG welding and flux-cored welding are highly versatile techniques capable of welding various materials, including aluminum, steel, and stainless steel. However, there are specific situations where one method may be more suitable than the other.

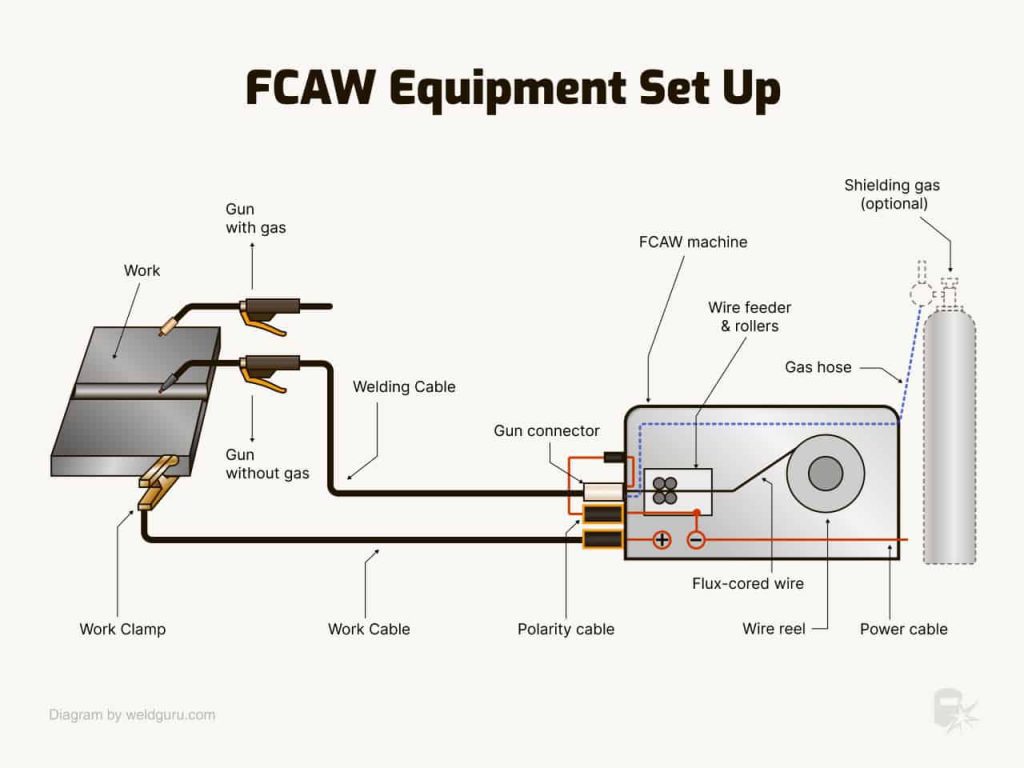

Below is an illustration depicting the process of flux-cored arc welding (FCAW).

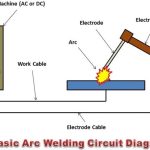

Below is an illustration showcasing the basic setup for metal inert gas (MIG) welding or gas metal arc welding (GMAW).

![Metal Inert Gas (MIG) Welding or Gas Metal Arc Welding (GMAW) Setup Illustration]

These illustrations provide a visual representation of the welding processes, helping to demonstrate their respective setups and procedures.

I have rewritten the text in English, ensuring clarity and coherence while maintaining the conversational tone and adhering to the English language.]