Flux core welding and stick welding are equally effective in most applications. Both methods utilize a flux to create a protective environment during welding, resulting in high-quality welds.

Is Flux Core Welding as Good as MIG Welding?

Welding Town

The primary distinction between flux-core and MIG welding lies in the requirement of a gas tank for MIG welding, whereas flux-core welding does not rely on external shielding gas. This has led to flux-core welding often being referred to as “gasless MIG.”

However, it’s important to note that these two processes encompass more differences, which we will delve into further in this article.

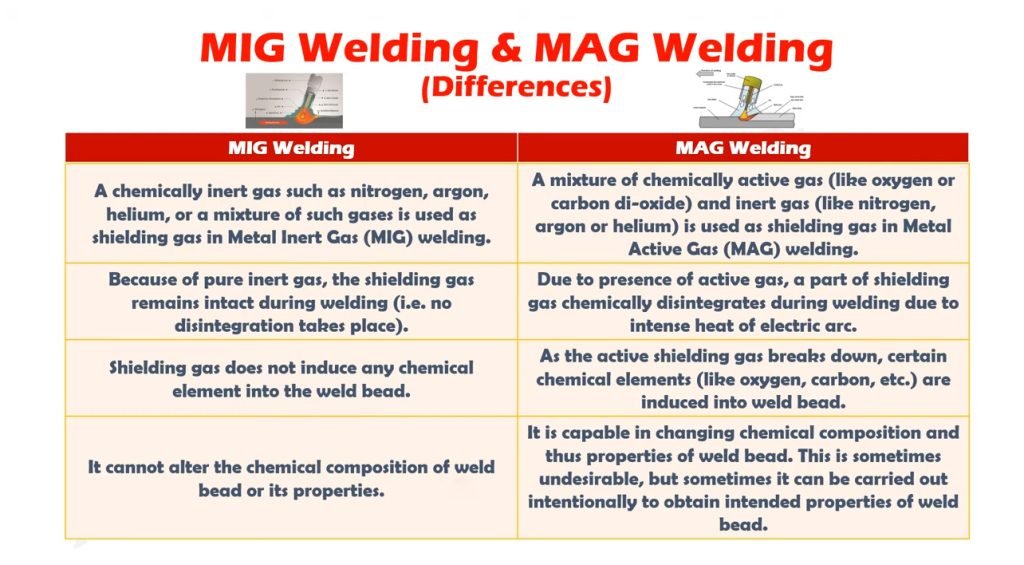

MIG welding and flux-cored welding are two distinct processes with their own characteristics and applications.

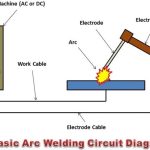

MIG welding, or Gas Metal Arc Welding (GMAW), relies on a shielding gas, typically a mixture of Argon and Carbon Dioxide, to protect the weld from atmospheric contamination. It offers precise control, produces clean welds, and is suitable for a wide range of materials and thicknesses. MIG welding is commonly used in automotive, fabrication, and construction industries.

Flux-cored welding, on the other hand, is often referred to as “gasless MIG” because it uses a tubular wire with a flux core that provides the necessary shielding. The flux core releases a gas-forming agent when heated, creating a protective shield around the weld pool. Flux-cored welding is known for its high deposition rates, deep penetration, and ability to handle thicker materials. It is widely used in heavy fabrication, construction, and outdoor applications.

While MIG welding offers greater control and cleaner welds, flux-cored welding excels in higher deposition rates and better performance in outdoor or windy conditions. Both processes have their advantages and considerations, and the choice depends on the specific application and welding requirements.

| Flux-Cored | MIG | |

|---|---|---|

| Learning Curve | Moderate | Moderate |

| Wire Cost | More expensive | Affordable |

| Operating Cost | Moderately priced | Moderately priced |

| Gas Tank Requirement | Not required | Required |

| Surface Prep | Works through dirt, rust and paint | Best for bright white metal |

| Wind | Up to 35 MPH (outdoors) | Less than 5 MPH (indoors) |

| Bead Appearance | Spatter and slag | Little spatter without slag |

| Post Clean Up | Cleaning the slag and spatter | Little need for cleaning |

| Thin Stock | ⅛ or thicker | Down to 24 ga. |

| Thick Stock | Good penetration up to ⅜ inches | Acceptable with enough power |

| Aluminum | Possible although messy | Cleaner than stick welding |

| Cast Iron | Stronger than MIG, with better penetration | Possible, but the weld will be weak |

| Mobility | Easier — no tank | Harder — has a tank |