Are you interested in diving into the world of welding? Two popular welding processes you may come across are Flux Core and MIG welding.

The Wire Involved in Flux Core Welding and MIG Welding

021208.com

While both techniques use a wire electrode to create welds, there are key differences between Flux Core and MIG welding. In this article, we will explore these differences to help you understand which method is best suited for your welding needs.

If you’re short on time, here’s a quick comparison of the flux-core and MIG welding processes:

| Flux-Cored | MIG | |

|---|---|---|

| Learning Curve | Moderate | Moderate |

| Wire Cost | More expensive | Affordable |

| Operating Cost | Moderately priced | Moderately priced |

| Gas Tank Requirement | Not required | Required |

| Surface Prep | Works through dirt, rust and paint | Best for bright white metal |

| Wind | Up to 35 MPH (outdoors) | Less than 5 MPH (indoors) |

| Bead Appearance | Spatter and slag | Little spatter without slag |

| Post Clean Up | Cleaning the slag and spatter | Little need for cleaning |

| Thin Stock | ⅛ or thicker | Down to 24 ga. |

| Thick Stock | Good penetration up to ⅜ inches | Acceptable with enough power |

| Aluminum | Possible although messy | Cleaner than stick welding |

| Cast Iron | Stronger than MIG, with better penetration | Possible, but the weld will be weak |

| Mobility | Easier — no tank | Harder — has a tank |

1. MIG Welding: The Basics

MIG welding, also known as Metal Inert Gas welding or Gas Metal Arc Welding (GMAW), is a widely used welding process. In MIG welding, a continuous wire electrode is fed through a welding gun, which also supplies a shielding gas to protect the weld from atmospheric contamination. The shielding gas, typically a mixture of argon and carbon dioxide, creates a stable arc and prevents oxidation of the weld. MIG welding is versatile and suitable for various metals, including stainless steel, carbon steel, and aluminum.

2. Flux Core Welding: The Fundamentals

Flux Core welding, on the other hand, is a variation of MIG welding that utilizes a hollow wire electrode filled with flux. This flux serves multiple purposes, including generating a shielding gas to protect the weld and providing a fluxing agent to remove impurities and produce cleaner welds. Flux Core welding does not require an external shielding gas, making it more portable and suitable for outdoor applications. It is commonly used in heavy-duty applications and welding thicker materials, including structural steel and heavy machinery.

3. Shielding Gas Considerations

One of the significant differences between Flux Core and MIG welding lies in the shielding gas used. In MIG welding, an external shielding gas is necessary to protect the weld from contaminants. The specific gas mixture is determined by the type of metal being welded and the desired weld characteristics. On the other hand, Flux Core welding utilizes a flux-cored wire electrode that releases a shielding gas when heated, eliminating the need for an external gas cylinder. This makes Flux Core welding more convenient in certain situations, particularly in outdoor or windy environments.

Flux-Core Vs. MIG Welding – The Similaritie

021208.com

Flux-core and MIG welding are among the most popular welding techniques.

4. Welding Position and Penetration

Another difference to consider is the welding position and penetration capabilities of Flux Core and MIG welding. Flux Core welding excels in vertical and overhead welding positions, providing better penetration and deposition rates. The flux within the wire electrode helps support the molten metal, allowing for a more stable arc and improved weld quality. MIG welding, while versatile, may require adjustments and additional techniques to achieve satisfactory welds in vertical and overhead positions.

5. Wire Electrode Selection

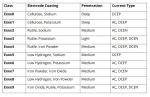

Choosing the right wire electrode is crucial for both Flux Core and MIG welding. For MIG welding, solid wire electrodes are used, and the wire composition must match the base metal being welded. Flux Core welding employs flux-cored wire electrodes, which come in two variations: self-shielded (gasless) and dual-shielded (with additional shielding gas). The choice of wire electrodes depends on factors such as metal type, welding position, and desired weld characteristics. Consulting welding charts or seeking professional guidance can help ensure the appropriate wire electrode selection for your specific welding application.

6. Application Considerations

When deciding between Flux Core and MIG welding, consider the specific requirements of your welding project. MIG welding is versatile, provides cleaner welds, and is well-suited for thinner materials and general fabrication. Flux Core welding, on the other hand, offers deeper penetration, better performance in outdoor conditions, and is more suitable for heavy-duty applications and thicker materials.

In conclusion, Flux Core and MIG welding are two popular welding techniques with distinct characteristics. MIG welding utilizes an external shielding gas, providing versatility and clean welds, while Flux Core welding utilizes a flux-cored wire electrode, offering convenience, better penetration, and performance in demanding applications. Understanding the differences between these methods will help you make an informed decision when selecting the appropriate welding process for your specific project. So, put on your welding helmet and start creating strong and precise welds with confidence!