When it comes to plasma cutting, selecting the right consumables and following proper guidelines is crucial for achieving optimal results. Here are some essential tips to consider when choosing consumables and using your plasma cutter effectively:

Consult your owner’s manual, follow these Plasma Cutting tips

Welding Town

1. Cut Height and Torch

Distance Maintaining the ideal cut height is essential to prevent issues such as angularity, wider kerfs, dross, and warping on thin materials. Ensure that your CNC machine and height control maintain the recommended torch distance from the workpiece. Moving the torch too high or too close can lead to collisions or incomplete cuts.

2. Consult the Operator’s Manual

Your plasma system’s operator’s manual is a valuable resource for achieving excellent cut quality. It contains detailed cut charts with information about cutting mild steel, stainless steel, and aluminum. These charts cover various material thicknesses, provide consumable recommendations, and offer settings such as kerf, torch-to-work distance, initial pierce height, pierce delay time, cut speed, and arc voltage. Always refer to your manual for specific settings and adjustments.

3. Choose the Right Consumables

Selecting the correct consumables for your plasma cutting system is crucial. Ensure that you choose the appropriate parts by double-checking the part numbers and matching them with those specified in your system or operator’s manual. Many consumable parts may appear similar, so verifying compatibility is essential.

4.Set Amperage Based on Consumables

Amperage is typically not included in cut charts because it should be determined by the amperage rating of your nozzle. Set your system to the amperage that matches your nozzle. Setting the amperage too low can result in low energy density, leading to dross formation or inadequate penetration. Exceeding the maximum amperage requirements of the consumables can cause rapid wear and nozzle failure. Lower amperage consumables and settings generally yield better cut quality, while higher amp settings enable faster cutting.

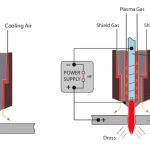

5. Shielded vs. Unshielded Consumables

Select shielded consumables if your CNC cutting table is equipped with an ohmic sensing circuit that relies on electrical contact with the shield and the material for surface location detection. If your machine lacks ohmic sensing, opt for unshielded consumables.

6. Proper Cut Height

Maintaining the correct cut height is crucial to achieve precise cuts. Deviating from the suggested cut height by more than approximately 0.005 inches can result in angularity, wider kerfs, dross, and potential warping on thin materials. Applying a water-based gas metal arc welding (GMAW) antispatter spray to the torch tip can help prevent debris from sticking to the consumables.

7. Pay Attention to Pierce Height

Pierce height is as important as cut height for ensuring long consumable life. Setting the pierce height too low can lead to the spatter blowing back and damaging the nozzle after only a few starts. Piercing too high can cause excessive pilot arcing and premature nozzle damage. The recommended pierce height is generally one and a half to two times the correct torch-to-work distance.

8. Arc Voltage Measurement

Arc voltage measurement, found in the cut charts, refers to the actual measurement between the electrode inside the torch and the material being cut. Longer plasma arcs result in higher arc voltage. The voltage setting listed in the manual provides the correct cut height assuming new consumables. Adjustments may be required if your consumables are worn.

9. Regular Maintenance and Calibration

Regularly inspect and maintain your consumables for optimal performance. Replace consumables when necessary, following the manufacturer’s guidelines. Ensure that your height control is correctly calibrated to maintain accurate cut and pierce heights.

Are You Changing Consumables Frequently? Here’s Why

Welding Town

If you find yourself frequently changing consumables, there are several potential reasons:

- Changing consumables at the wrong time: Consumable wear is application-specific, so avoid replacing them based on arbitrary criteria. Replace consumables when they reach the recommended wear limits.

- Incorrect torch distance: Ensure your torch is positioned correctly, following the guidelines for cut and pierce height.

- Improper arc termination: Make sure the torch remains over the plate when the cut ends to avoid excessive hafnium ejection and arc start loss.

- Insufficient gas supply: Low flow rates can lead to nozzle destruction and pilot arc attachment to the inside of the nozzle orifice.

- Inadequate coolant flow: Proper coolant flow is crucial for optimal consumable wear. Flow restrictions can result in excessive heat buildup and rapid erosion.

- Poor work cable connection: A good electrical connection facilitates proper arc transfer and prevents excessive consumable wear and misfiring.

By following these tips, along with the guidelines provided in your owner’s manual, you can achieve better cut quality, longer consumable life, and cost savings in your plasma cutting operations.