How To Settings AC Frequency for Stacking Beads on Aluminum

AC frequency settings are a nice to-have feature but only if you understand what it does and where to use it. As a general rule, I use higher AC frequencies…

8 Tips to Improve Your Stainless Steel TIG Welding

TIG welding stainless steel can be intimidating for TIG welder beginners, especially when their welds turn out less than desirable despite following the same setup as a professional TIG welder.…

How to Weld: Top 10 Mistakes Made by Beginner Welders

Since the welding industry is constantly evolving with new technologies and emerging methodologies, even the most experienced master welder needs to look up information regarding welding practices from time to…

History of Welding: A Brief History

Welding has been around since ancient times. Read this article for a brief overview of welding history throughout the years. Welding History: A Welding TimelineWelding Town The invention and technical…

Best Welding Gas for TIG Welding Carbon Steel

Best Welding Gas for TIG Welding Carbon Steel

MIG Welding Troubleshooting Guide

Like any welding process, MIG welding has its complications. Even so, there is no reason to let common problems slow you down. With a bit of knowledge and some solid…

A Detail Mig Welder Troubleshooting Guide for the Operators grounding procedure

mig welder troubleshooting,mig welder not working,mig welding problems and solutions,troubleshooting a mig welder,mig welding troubleshooting guide,mig welding problems chart,mig welder problems feed wiremig welding troubleshooting,mig welder settings

Arc Welding vs. Laser Welding: what it is, and discussed its various applications

Arc welding and laser welding are two prominent welding methods used in many industries for joining metal components. While both techniques serve to create strong and durable welds, they differ…

Welding Electrodes – Learn About Types and Applications

Welding, a fundamental process in the world of metal fabrication, relies on a range of tools and materials to create strong and durable joints. One critical component of welding is…

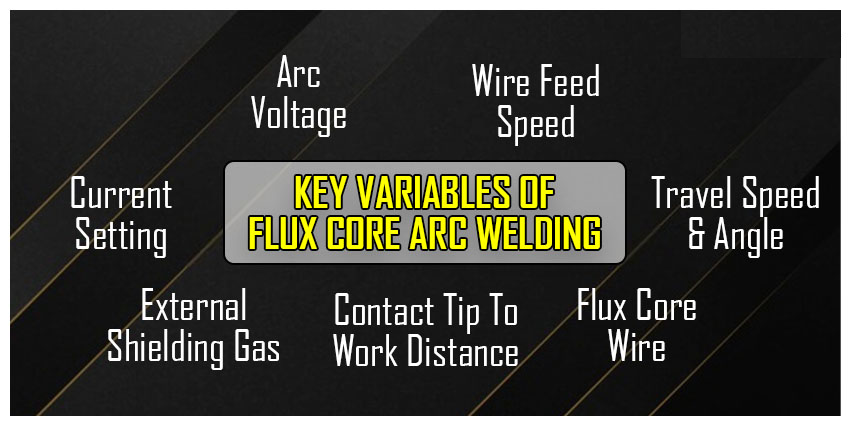

10 Main Advantages and Disadvantages of Flux Cored Arc Welding

Flux Cored Arc Welding (FCAW) is an arc welding technique that involves creating an arc between a continuous tubular filler metal electrode and the weld pool. flux cored arc welding advantages…