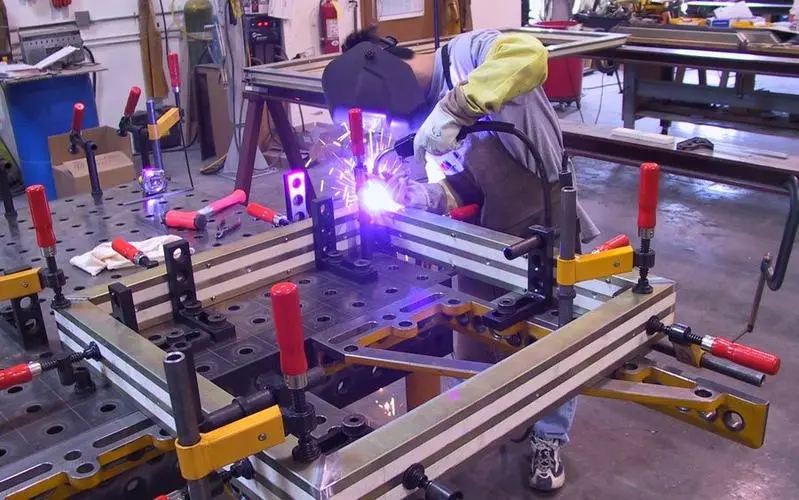

10 Essential Welding Tools For Every Welder

For beginners, diving into welding might feel intimidating due to the potential hazards and the array of welding tools involved, as working with heat and pressurized components can be overwhelming.…

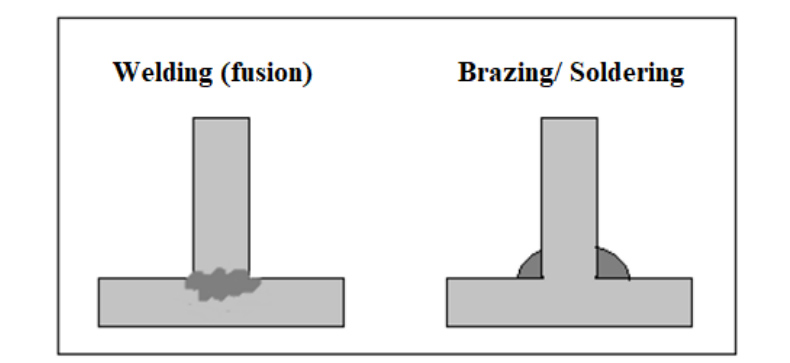

The Difference Between Soldering And Welding

In the metal fabrication sector, welding and soldering are vital techniques employed to join metal pieces by applying heat. To draw a comparison between welding and soldering, various factors will…

How to seal aluminum joint welds

When sealing or capping aluminum welds, is it necessary to drill holes to prevent gas expansion, as is done with welded steel? Reduce the chance of developing expanded gas inside…

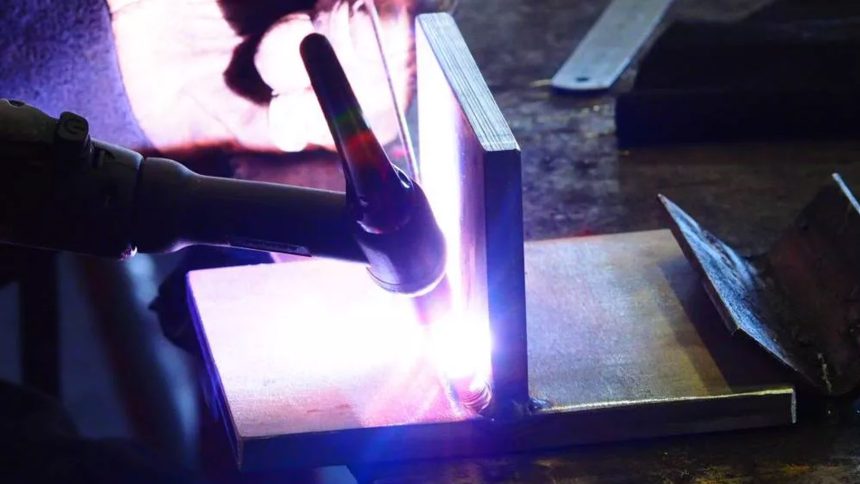

Step to Step (Gas, Amps, Alloys, Polarity, Tips, etc) for How to TIG Welding Steel

TIG welding, also known as Tungsten Inert Gas welding, is a highly valuable method for joining metals, especially steel. This technique involves heating the metals using an arc created between…

How Long Does It Professional Take to Become a Welder

In every line of work, there exists a distinct reputation when compared to other professions. The welding industry, for instance, relies heavily on skilled welders proficient in various techniques. Although…

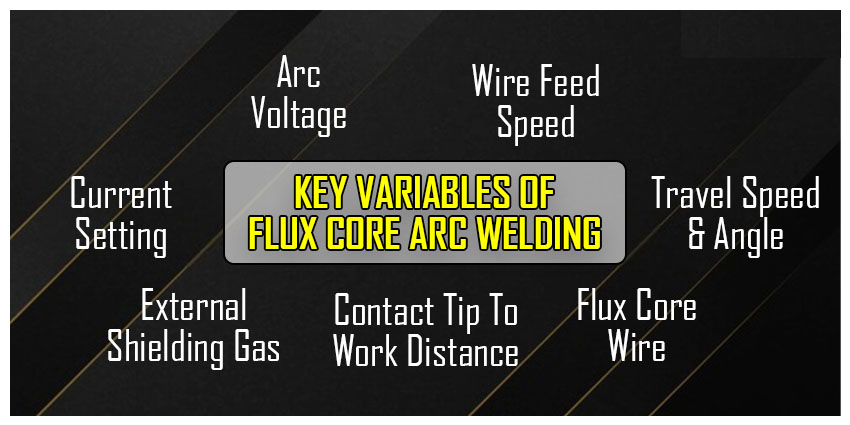

Advantages and Disadvantages of Flux Cored Arc Welding

Flux Cored Arc Welding (FCAW) is an arc welding technique that involves creating an arc between a continuous tubular filler metal electrode and the weld pool. 10 Main Flux Cored Arc Welding Advantages…

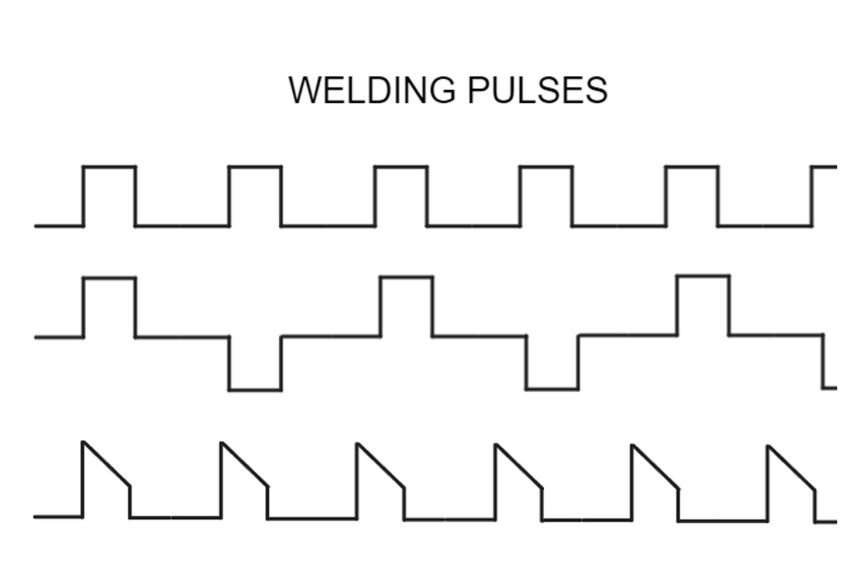

Everything To Know About Pulse Welding

When using a TIG welder to weld aluminum, it can be a challenging process due to its higher heat requirements compared to mild steel. The voltage needed for aluminum welding…

Best Flux Core Welders – MIG Welding Machine Reviews

Flux core welding and general MIG welding are similar methods used for both outdoor and indoor welding projects. However, flux core welding has certain advantages, especially when dealing with metals…

Step by Step (Amps, Voltage, Gas, And More) for How to TIG Welding Aluminum

Aluminum, an extraordinary and unparalleled metal, boasts a myriad of advantageous attributes that render it a prime choice for diverse projects. Given its exceptional properties, the practice of Tungsten Inert…

TIG welding aluminum: What you need to Know

Manufacturing products using aluminum offers numerous advantages, such as extended part life, reduced weight, and enhanced integrity in cold temperatures. This makes aluminum an ideal choice for various applications, including…