Best Welding Gas for TIG Welding Carbon Steel: When it comes to welding gas, you can find a wide array of gasses available to use. A quick check of one gas company’s website shows six pure gasses available for welding, along with six families of blended gas. Add in the different proportions for each mixture, and you will quickly get a headache from thinking about all the choices.

Best Welding Gas for TIG Welding Carbon Steel

Welding Town

Which gas is best for TIG welding carbon steel, and why? The best gas for TIG welding carbon steel is argon. Argon provides a good combination of features that produce clean, high-quality TIG welds in carbon steel. The benefits of argon as a shielding gas include:

- Protection from oxidation

- Good heat transfer

- Arc stability

- Reduced spatter

- Affordable price

Other gasses will work to TIG weld carbon steel, but argon is the best combination of price and weld quality. It should be your first choice when TIG welding carbon steel.

TIG Welding Basics

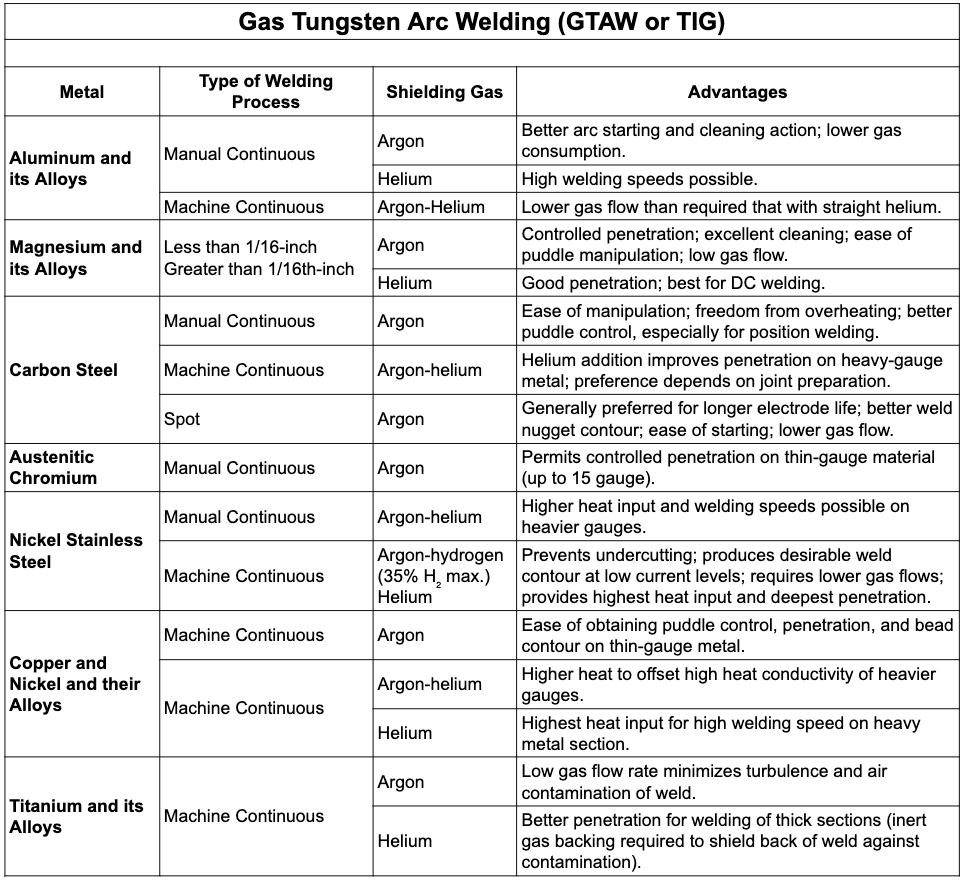

TIG stands for Tungsten Inert Gas. Officially, the name of the welding process is “gas tungsten arc welding,” or GTAW. It is sometimes called “heliarc” welding, short for helium (the original shield gas) arc welding. These names all mean the same thing.

TIG welding works like this: an electrode made of tungsten generates such intense heat (up to 11,000 degrees!) that the metal you are welding melts. The temperature is such that the metal would oxidize if exposed to oxygen. To protect the weld, the handpiece that holds the electrode feeds a steady stream of non-reactive gas over the weld.

The non-reactive gas keeps oxygen off of the weld bead for the crucial few seconds that it is hot enough to be reactive. Originally, helium was the preferred gas for shielding, hence the name “heliarc.” Now argon is preferred for welding carbon steel.

If you try TIG welding without any shielding gas, several things happen. None of them are good. First, your tungsten electrode will corrode and break, contaminating the weld with tungsten. It will be hard to keep an arc going, so you can’t weld very much. Finally, your weld will oxidize, causing the bead to turn black. The weld will also be brittle and weak.

TIG welding torches are built with a gas connection right in the handle. When you start welding, the gas flows over the weld to protect it. Some high-end TIG welders even have features that start the gas a little before the arc starts, and run it after the arc stops, to adequately protect the weld.

Shield Gasses

To get the best results from TIG welding, you need to use a shielding gas. The best shield gasses for TIG welding are inert. That is, they are gasses that don’t react with the weld or base metal at all. The most common inert gasses are argon and helium.

Argon

Pure argon is the best choice for welding carbon steel. Other gasses can be used, but they tend to be more expensive. Some other gases – even gasses used in other welding processes – will introduce problems if you use them to TIG weld carbon steel.

Argon is a colorless, odorless, tasteless gas. It makes up just under 1% of the earth’s atmosphere. Argon makes an excellent shield gas because it is non-reactive, produces a stable arc, and transfers heat well. Since it is so widely used, it is considered the standard for TIG welds. Other gasses are described as “hotter,” “cooler,” or otherwise different when compared to welds made with argon.

Since argon is present in the atmosphere, it tends to be relatively inexpensive. The industrial process used to produce pure oxygen and pure nitrogen also produces argon. Argon is heavier than air, so whatever gas is released in welding stays in the atmosphere to be recaptured again and again.

Welds made with argon shielding gas will be smooth and attractive, with no slag or oxidation visible. The ideal flow rate for argon should be 15-20 cubic feet per hour (CFH). If you reduce the flow rate, the gas won’t fully shield the weld, and you will start seeing porosity develop.

On the other hand, more gas flow isn’t better. If you raise the argon flow too high, it will create turbulence around the weld. Imagine the difference in a gentle flow from a hose compared to a high-volume stream. Flooding more gas into the weld area will cause the argon to splash and mix with air. This can create as many problems as too little shield gas.

Helium

Helium is also a good choice for TIG welding of carbon steel. It was the original gas used for TIG welding when the process was developed. It is also non-reactive and produces clean welds. Helium is considered “hotter” than argon because it transmits the heat of the arc better than argon. If you are welding with helium, you should turn the amperage down to prevent warping or other heat-related problems.

Helium is the preferred gas for welding thick pieces of aluminum. Since aluminum conducts heat well, it requires a hotter arc than steel to form a weld puddle. Many metalworkers find that aluminum that is to thick to weld with argon – even with the amperage cranked all the way up – welds just fine with helium.

Because of the improved heat transfer, you get a deeper weld with helium. The heat penetrates further into the joint than with argon. This is good for thick metal but can cause warping with thinner steel. You can also work faster with helium. Instead of getting a deep weld, you can apply the filler rod more quickly to finish the same joint in less time.

The biggest drawback to welding with helium is the price. It is lighter than air, so any helium released into the air floats up into space. There are pockets of helium present in the earth’s crust, but they are being used up. Once those are gone, they are gone and can’t be replaced. This makes helium pricey for welding.

You can get good TIG welds with helium, but the price discourages its use. If you don’t have an excellent reason to TIG weld using helium as a shielding gas, stick with argon.

Argon – Helium Mix

Since both argon and helium are good for TIG welding, it makes sense that blends of the two are also good shield gasses. The most common mixes are 25% helium / 75% argon, 75% helium / 25% argon, and a 50-50 mix of the two.

As you would expect, the welding performance of the blended gasses is a blend of the two shield gasses. Adding helium makes the arc hotter, and the weld penetrates deeper than pure argon, but not as hot and deep as pure helium. Since helium is more expensive than argon, the blends tend to be intermediate in price as well – higher than argon, but less than pure helium.

As with pure helium, helium – argon mixes should be avoided unless you have a good reason to buy them. These mixes won’t hurt the weld, but they aren’t great for your wallet.

When Helium Makes Sense

There is one situation when helium or a helium-argon mix makes sense for welding carbon steel: welding very thick material. The general rule is that you can TIG weld one-thousandth of an inch (.001) per amp. A 150-amp welder is suitable for 0.15-inch thick material, or about 5/32. A 250-amp welder can weld quarter-inch steel. These numbers are calculated based on using argon as a shielding gas.

You can stretch the thickness a little if you use helium instead. Helium runs about 20% hotter than argon, so your 150-amp welder could stretch and weld material up to 0.18, or 3/16 inch, thick. A 250-amp welder could weld material 0.30 inches thick. It isn’t a huge difference, but using helium as a shielding gas can help you weld material a little thicker than usual.

Argon – Hydrogen Mix

Some TIG welding applications use argon blended with low levels of hydrogen. The blends used for TIG welding range from 2% to 15% hydrogen, with the balance being argon. The most common use for argon–hydrogen blends is for welding stainless steel.

The most important reason to use hydrogen blends is that oxygen reacts better with hydrogen than it reacts with steel. Having a trace of hydrogen in the shield gas blend guarantees that the environment will be free of oxygen and offers extra protection against oxidation. This is important for welding stainless steel for food service applications because it doesn’t leave any rough spots where germs can hide.

Adding hydrogen to argon also increases weld heat, as helium does. This lets you get a deeper weld for thick material or travel faster on thin material. You can also use it like helium to weld thicker material, but you are probably better off using helium for this.

There is no good reason to use argon–hydrogen mixes for welding carbon steel. These mixes are needed for welding stainless, but not carbon steel.

Gasses That Don’t Work

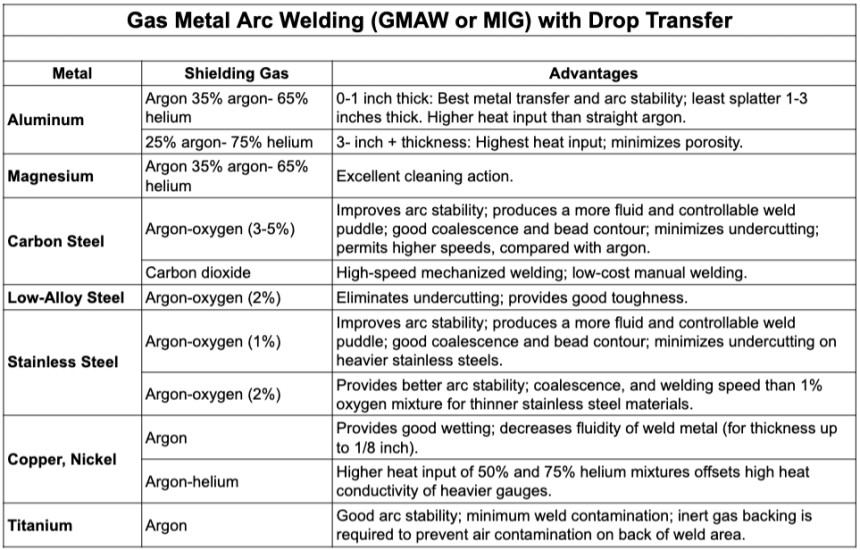

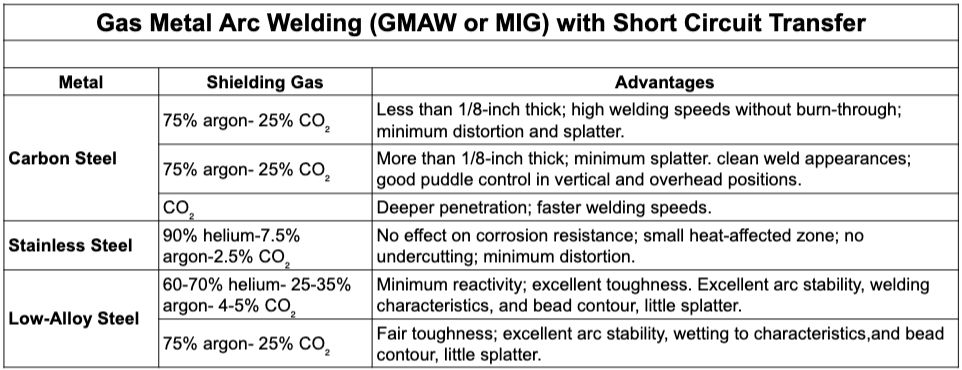

Some welding shield gasses won’t work for TIG welding. New TIG welders often wonder if they can use the same shield gas for TIG welding that they use for MIG. Gas blends for MIG welding won’t work for TIG welding. Stick with inert gasses for TIG.

Carbon Dioxide

Most MIG welding gasses include some proportion of carbon dioxide (CO2). Some MIG applications even use pure CO2 as a shielding gas. CO2 is less expensive than argon but produces a rougher weld. It is used in MIG welding when speed is more critical than weld appearance.

CO2 won’t work for TIG because it is a reactive gas. The high heat of TIG and the tungsten electrode will cause problems if you use CO2 as a shielding gas. Weld quality will be poor, and you will find bits of tungsten in the weld bead. Avoid CO2 for TIG welds. This goes for both pure CO2 and argon – CO2 blends.

The rods for TIG welding are formulated differently than the rods for MIG welding. MIG rods include flux that is present to burn off impurities in the metal. The CO2 in MIG gas is part of this process. TIG rods are pure filler with no flux. These rods will react with the CO2 in the weld and create porosity or cracking.

Tri-Mix

Another standard MIG shield gas is “tri-mix.” Tri-mix is a combination of argon, helium, and CO2. The mixes are usually either mostly helium or mostly argon, with just a tiny bit of CO2. Some of these mixes work well when MIG welding stainless steel to get good color match and weld speed. Blends with a higher portion of CO2 are suitable for MIG welding rusty or dirty metal. The CO2 acts as a flux to clean the surface.

Since tri-mix contains carbon dioxide, it is a poor choice for TIG welding. The CO2 will react with the tungsten electrode and contaminate the weld.

Nitrogen

The significant advantage of nitrogen is that it is cheap. The air we breathe is 78% nitrogen, so it’s easy to come by. Nitrogen is sometimes used as a purge gas when TIG welding stainless steel. It is also used in MIG welding for some applications.

Nitrogen works as a purge gas on the backside of a TIG weld because it isn’t exposed to high arc temperatures. Purge gas protects the back of a weld (especially stainless steel) from oxidation while it’s hot. However, nitrogen will react with the tungsten electrode and ruin the weld if it’s used as a shielding gas.

Reactive Gasses

There are some other gasses that you should never have around when welding. Any flammable or reactive gas is dangerous in a welding situation. Propane, butane, acetylene, and oxygen will all start fires if you release the gas near a welding arc. Keep these gasses well away from your welding area.

Gas Safety

TIG welding is almost always performed indoors because the shield gas can get blown away too quickly outside. You need a still atmosphere to get the best TIG welds. However, you do need some ventilation when TIG welding. Both argon and helium present a low (but real) asphyxiation risk.

Argon and helium are both colorless and odorless. If you are in an area with dangerous levels of argon or helium, the first sign that there is a problem is a loss of consciousness. Once you’ve passed out, you cannot take any action to help yourself, and you will die. Be aware of danger spots when using shield gas.

Argon is heavier than air. When used in high concentrations, it will pool in low-lying areas. Picture where water would puddle up if your shop gets flooded. That’s where argon pools, too. This presents the most significant danger when working with pipes and enclosed tanks. Argon can pool in a tank without being seen. Never enter an enclosed tank, pipe, or chamber where TIG welding has taken place until it has been thoroughly vented.

Helium is less of a problem because it rises. However, it can still get trapped in enclosed tanks and pipes. Helium pools at the top of a tank rather than the bottom. Vent or open the tank to allow the helium to escape before entering.

Handling Gas Cylinders

Cylinders of welding gas are filled to pressures of 200 to 300 pounds per square inch. They can be dangerous if handled roughly or improperly. Follow these safety rules when handling gas cylinders:

- The best way to move cylinders is on a dolly or rolling cart

- If you must move a cylinder, not on a cart, roll it along its bottom edge. Don’t lift it off the ground to carry it.

- Remove the regulator and put on the travel cap when moving cylinders

- Store cylinders upright, no on their sides

- Store cylinders at least 20 feet away from flammable materials

- Have a dedicated cylinder storage location. Make sure the cylinders can’t accidentally be knocked down when stored.

- When welding, keep the cylinder far enough from the weld that sparks or slag won’t touch it. Also, make sure it can’t accidentally create an arc from the welder

- Open the pressure valve slowly to protect the regulator

- Don’t use hoses that are cracked, worn, or damaged

Conclusion

TIG welding carbon steel requires you to use some shielding gas to protect the weld. Not using any shielding gas is a recipe for a bad, ugly weld. Argon is the best shield gas for carbon steel. It provides a good balance of weld quality and cost. Helium and argon-helium blends will also work but at a higher price. Avoid using gas blends for MIG welding that contain CO2.