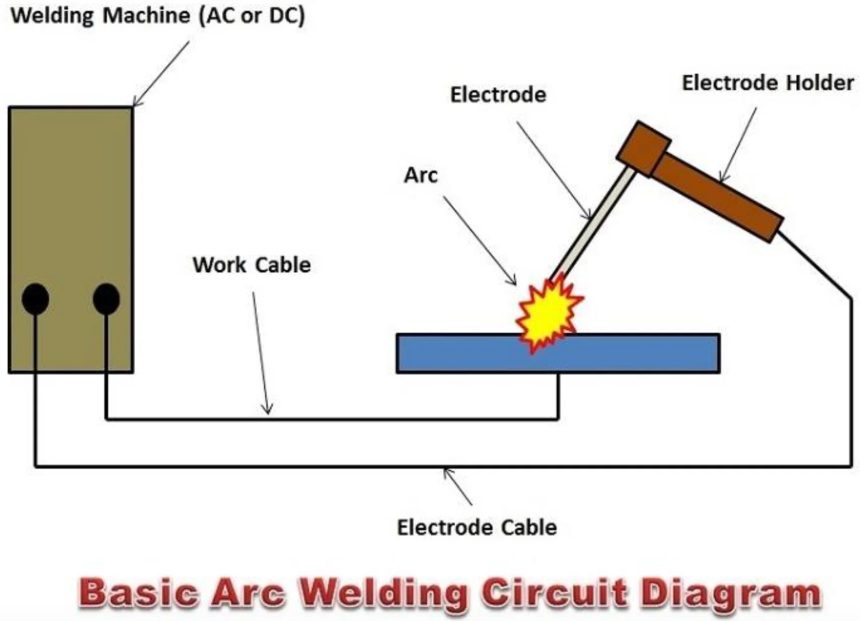

electricity to generate high levels of heat, which in turn melts the metals, creating a molten pool. As the metals cool and solidify, they fuse together, forming a single material. This fusion is the key factor behind the strength and durability of welded structures.

Arc welding is the process of melting two metals

Welding Town

Stick welding

Stick welding, also known as shielded metal arc welding (SMAW), is a widely utilized form of arc welding. It incorporates the following characteristics:

- Fixed length electrode: Stick welding employs a consumable electrode with a fixed length, which gradually melts as it creates an arc and deposits filler metal into the weld joint.

- Suitable for various surfaces: Stick welding can be used on a range of surfaces, including dirty, painted, and rusty ones. This versatility makes it highly popular in repair and maintenance industries.

- Difficult to master: Stick welding is considered a challenging process to master. Striking and maintaining an arc requires skill and practice. The learning curve can be lengthy, but the effort invested is rewarding.

- Some cleanup required: Stick welding does produce some slag and spatter, necessitating a certain degree of post-weld cleanup. However, this is typically manageable compared to other welding processes.

- Indoor and outdoor application: Stick welding is suitable for both indoor and outdoor environments, providing flexibility for welding projects in various settings.

- Broad material compatibility: Stick welding is compatible with a wide range of metals and alloys, including steel, aluminum, and iron. This versatility makes it a go-to choice for many applications.

Stick welding is widely used in industries such as construction, fabrication, and maintenance due to its robustness and ability to weld on diverse surfaces. While it may require patience and dedication to acquire the necessary skills, stick welding remains a highly valued and widely employed welding process.

The stick welding process

The stick welding process involves the following steps:

- Stick electrode: Stick welding uses a fixed-length electrode that is coated with a flux consisting of powdered metals. The flux serves multiple purposes, including creating a shielding gas and providing filler material for the weld.

- Flux and shielding gas: When the stick electrode is heated by electricity, the flux coating creates a shielding gas to protect the weld from atmospheric contamination. This eliminates the need for an external gas supply, making stick welding suitable for remote and challenging environments.

- Filler material and weld creation: As the stick electrode melts, it provides filler material that combines with the base metal to create the weld. The molten electrode and flux coating form a protective slag layer that covers the weld as it cools.

- Cleanup and appearance: Stick welding can produce spatter and slag, resulting in the need for some post-weld cleanup. The appearance of stick welds can vary based on the skill of the welder and the specific welding parameters used.

- Flux coating and weld characteristics: Different types of flux coatings can be used, allowing for adjustments to the characteristics of the weld. Additionally, the angle at which the weld is performed can also affect the outcome.

Where is stick welding used?

Stick welding finds application in various scenarios:

- Remote and difficult environments: Stick welding is a preferred choice for welding in outdoor and hard-to-reach places due to its portability and self-shielding nature. It can be performed even in adverse weather conditions.

- Versatile applications: Stick welding is used in a wide range of industries, including construction, infrastructure, maintenance, and fabrication, where the ability to work in diverse environments is required.

Due to its convenience, portability, and ability to operate without an external gas supply, stick welding remains a popular choice for welding tasks that demand mobility and versatility.