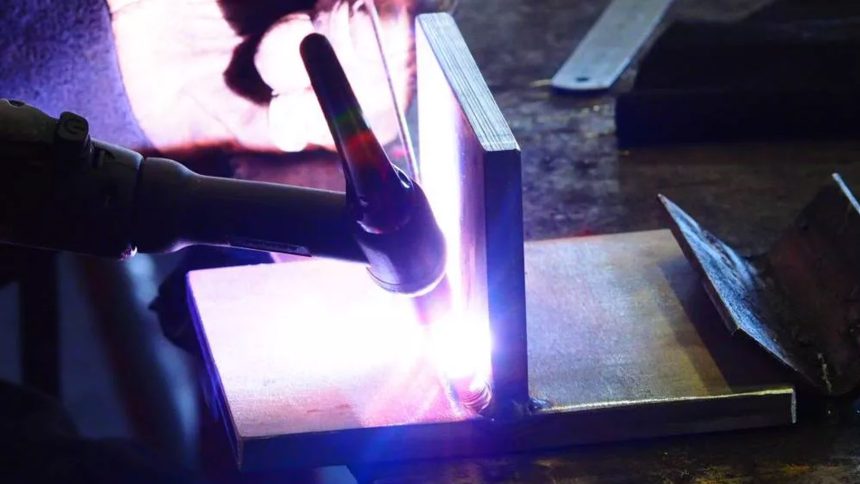

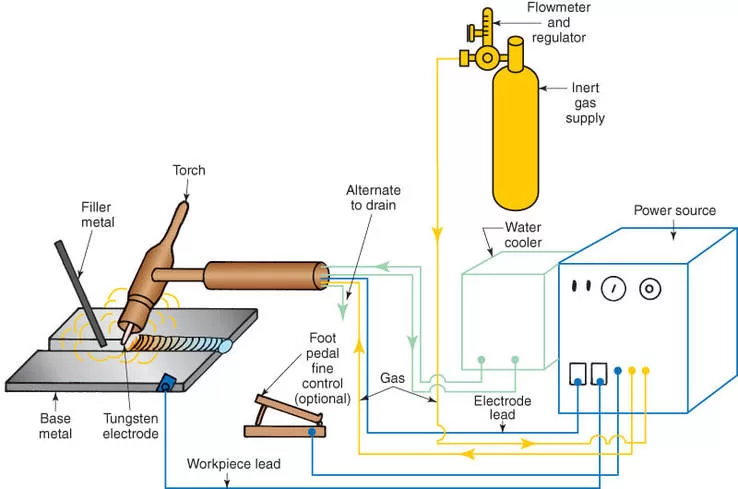

Before talking about the TIG welding advantages, let us understand Tungsten Arc Welding (TIG). In TIG welding an arc is created between a non-consumable tungsten electrode and the metal being welded. The arc produces the required heat to melt the work and the shielding gas (pure argon), fed through the torch, keeps oxygen in the air away from the molten weld pool and the hot tungsten.

TIG welding advantages

Welding Town

Tungsten is used for the electrode both because of its high melting temperature and good electrical characteristics. When filler metal becomes necessary, a separate filler rod is fed into the arc stream either manually or mechanically. Since no flux is required, the weld joint is clean and free of voids.

TIG welding has several advantages though it may not be suitable for all types of welding requirements. When manufacturing consumer products where appearance is of importance, then the choice has to be TIG. Jobs that call for code requirements such as nuclear work, piping, and high profile consumer goods often require at least the first weld in the pipe joint to be TIG for an effective bond. In some cases all the passes on a multi-pass pipe weld may have to be TIG, if high quality and code requirements demand TIG.

The widely accepted fact in the welding technology is that a TIG welder will often be a better quality weld than a MIG welder. For instance, a small assembly within a car engine is made of 1/8″ (3.2 mm) aluminum. While MIG will certainly be able to do the job faster, the welding engineers preferred the TIG welding process for reasons of precision. It is a fact that when one has to weld materials in the five-thousandths inch range, the common welding processes may not be suitable. Even MIG welding or Stick welding may not be right because they would put too much heat into the metal. However, when welding thick metal you should opt for MIG welding or Stick welding as they can weld 1/2 in. material much faster.

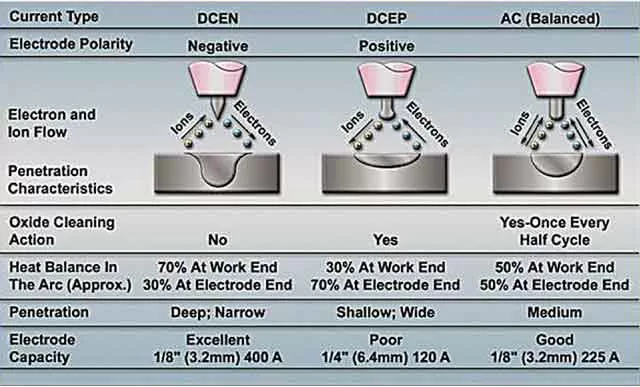

When selecting TIG welding machine, you should know how much power and sophistication are needed for the job. It is also necessary to ascertain the volume of such jobs currently on hand and the projected business for TIG welding. The next question is – does one need AC or DC power source. Professionals say that aluminum and magnesium are two metals that are best welded using the AC output from the power source. Steels and stainless steels are most often welded with DC output. To weld a variety of metals, use a combination AC/DC machine.

If the power source is either moved around the shop, or taken from one site to another, then a portable welder is needed. There are two basic ways to accomplish portability – inverters and engine-driven welders. Inverters are now available that weigh around 13 kg and come with handles for easy shifting around. Engine-driven machines are used when a welder has no access to primary power for welding. Engine-driven power sources are needed for field maintenance, pipe welding, or construction work.

TIG welding is largely used for welding different kinds of alloys of aluminum and stainless steel where quality is of importance. TIG welding is mainly used in aeronautical constructions and in the chemical and the nuclear power industry.