MIG welding, a widely used welding process, emerged in the aftermath of World War II. It evolved from gas-shielded metal welding and has since become highly favored. Among all welding techniques, MIG welding stands out as the ideal choice for steel applications, particularly when working with stainless steel and mild steel.

Are you new to MIG welding? Learn about the various applications of MIG welding with this beginner’s guide.

Welding Town

If you’re an experienced individual seeking to enhance your DIY projects at home by adding welding wire to your arc, then MIG welding, also known as GMAW (Gas Metal Arc Welding), will definitely pique your interest. In this comprehensive guide, we will delve into the world of MIG welding, providing you with valuable insights and all the necessary information to help you embark on your welding journey.

What is MIG Welding?

MIG welding, a continuous arc welding technique, utilizes an inert shielding gas that flows from the torch onto the workpiece, safeguarding the welding pool. This process ensures optimal protection during the welding process.

One of the key advantages of MIG welding is its continuous wire welding nature, which makes it highly suitable for high productivity projects. Additionally, the presence of gas as a shielding agent enables the process to operate without the formation of slag, further enhancing its efficiency and cleanliness.

WHAT DOES MIG MEAN?

MIG stands for Metal Inert Gas, which is also commonly referred to as wire welding or Gas Metal Arc Welding (GMAW). It has gained immense popularity as one of the most widely used welding processes, following shielded metal arc (stick) welding. MIG welding is categorized among the four main types of welding processes, with the other three being Tungsten Inert Gas (TIG) welding, Stick Welding or Shielded Metal Arc Welding (SMAW), and Flux-Cored Arc Welding (FCAW).

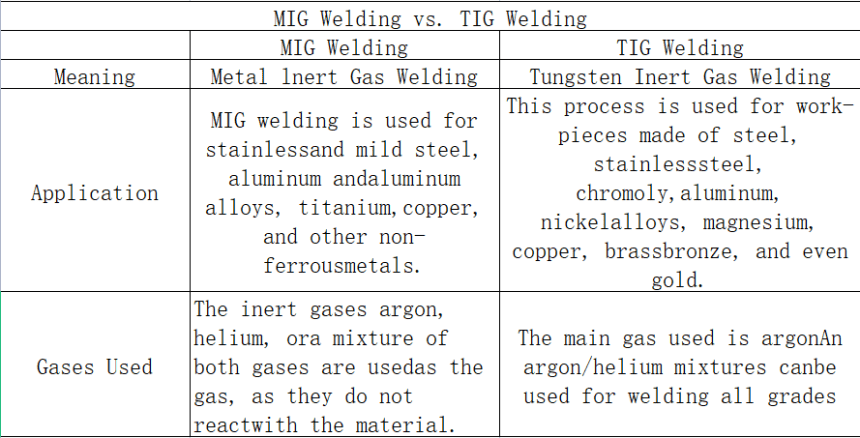

MIG welding is often compared to TIG welding, which stands for Tungsten Inert Gas. Let’s explore the differences between these two welding procedures.

| MIG Welding vs. TIG Welding | ||

| MIG Welding | TIG Welding | |

| Meaning | Metal lnert Gas Welding | Tungsten Inert Gas Welding |

| Application | The main gas used is argon argon/helium mixtures can be used for welding all grades | MIG welding is used for stainless and mild steel, aluminum and aluminum alloys, titanium, copper, and other non-ferrous metals. |

| Gases Used | MIG welding is used for stainless and mild steel, aluminum and aluminum alloys, titanium,copper, and other non-ferrous metals. | The inert gases argon, helium, or a mixture of both gases are used as the gas, as they do not react with the material. |

The Science Behind MIG Welding

Metal Inert Gas (MIG) welding harnesses the power of electricity to melt and join metal pieces, resulting in robust, long-lasting, and visually appealing welds. This welding technique relies on the utilization of shielding gas, which serves two crucial purposes: preventing contamination or oxidation of the weld pool and reducing the combustibility of the materials involved. Through the careful application of shielding gas, MIG welding ensures high-quality welds with excellent durability and aesthetic appeal.

HOW DOES IT WORK?

In MIG welding, an electrical current is utilized to generate an arc between an electrode wire and the metal piece intended for welding. This arc causes the wire to melt and be deposited, thereby creating the actual weld. The process takes place at the nozzle of the MIG torch, which resembles a handheld fuel dispensing gun. As the torch operates, it simultaneously supplies the electrode wire and inert shielding gas into the weld. Once the heat source, represented by the torch, is removed, the weld pool cools down, solidifies, and transforms into a newly formed molten metal, thus completing the weld.

What Supplies Do You Need to MIG Weld?

When you are prepared to begin MIG welding, it’s essential to have the following supplies on hand:

- MIG Welding Machine: An appropriate MIG welding machine that suits your specific welding needs.

- Welding Helmet: A high-quality welding helmet with proper eye protection and a shield to safeguard your face and eyes from sparks, UV rays, and debris.

- Welding Gloves: Heat-resistant gloves that provide excellent dexterity and protection for your hands while handling hot materials.

- Welding Apron: A durable welding apron to shield your body and clothing from sparks, splatter, and potential burns.

- Welding Jacket: A flame-resistant jacket or coat designed for welding purposes to provide added protection to your upper body.

- Welding Electrodes/Wire: The appropriate type and size of welding electrodes or wire suitable for your welding project and the metal you are working with.

- Welding Gas: The specific shielding gas required for your welding process, such as a mixture of argon and carbon dioxide (CO2) or pure argon gas.

- Wire Brush: A wire brush for cleaning the weld joint and removing any debris or impurities before welding.

- Clamp or Magnet: Clamps or magnets to secure the workpiece in place and ensure stability during welding.

- Safety Equipment: Additional safety equipment such as earplugs, safety glasses, and protective clothing to ensure your overall safety while welding.

Having these supplies readily available will enable you to start your MIG welding journey smoothly and safely.

Top 14 Useful MIG Welding Tips for Beginners

Welding Town

MIG Welding Applications

MIG welding offers a relatively gentle learning curve compared to TIG welding or traditional oxyacetylene welding. It is a versatile technique employed by both beginners and seasoned professionals. Let’s explore some of the applications where MIG welding finds its use:

- Automotive Repairs: MIG welding is widely utilized in the automotive industry for repairing body panels, exhaust systems, and fabricating custom parts.

- Metal Fabrication: This welding process is favored in metal fabrication shops for joining and assembling various metal components, such as gates, fences, frames, and structural elements.

- Home DIY Projects: MIG welding appeals to DIY enthusiasts who undertake projects involving metalwork, such as building furniture, creating metal sculptures, or repairing household items.

- Industrial Manufacturing: MIG welding is commonly employed in industrial settings for mass production of metal products, including machinery, equipment, and structural components.

- Maintenance and Repair Work: Whether it’s fixing agricultural machinery, industrial equipment, or repairing metal structures, MIG welding is a reliable choice for efficient and effective repairs.

- Shipbuilding and Marine Applications: MIG welding plays a significant role in the construction of ships, boats, and other marine vessels, ensuring strong and durable welds that withstand harsh marine environments.

- HVAC Systems: MIG welding is utilized in the fabrication and installation of heating, ventilation, and air conditioning (HVAC) systems, including ductwork and components.

- Artistic Creations: Artists and sculptors utilize MIG welding to bring their creative visions to life, shaping and joining metal to create unique and expressive works of art.

These are just a few examples of the diverse range of applications where MIG welding proves its versatility and utility.

MIG Welding Pros and Cons

MIG welding offers several advantages, with the absence of slag production being a key benefit. It is particularly advantageous for hobby welders. However, it is important to note that no welding technique is universally perfect for all applications, and MIG welding is no exception. Here is an overview of the most common pros and cons associated with metal inert gas welding:

Pros of MIG Welding:

- No Slag Formation: MIG welding produces clean and tidy welds without the need for slag removal, saving time and effort.

- High Productivity: The continuous wire feed and faster deposition rate make MIG welding highly efficient, allowing for increased productivity.

- Versatility: MIG welding can be used on a wide range of materials, including stainless steel, mild steel, aluminum, and copper alloys.

- Easy to Learn: MIG welding has a relatively short learning curve, making it accessible to beginners and hobbyists.

- All-Position Welding: MIG welding can be performed in various positions, including flat, horizontal, vertical, and overhead, providing versatility in different welding scenarios.

Cons of MIG Welding:

- Limited Portability: MIG welding requires a power source and shielding gas, making it less portable compared to some other welding techniques.

- Surface Preparation: Proper cleaning and preparation of the workpiece are crucial for successful MIG welding, requiring attention to detail and cleanliness.

- Wind Sensitivity: MIG welding can be affected by wind, as the shielding gas can be blown away, leading to poor weld quality if not adequately protected.

- Equipment Cost: MIG welding machines and associated equipment can be more expensive compared to some other welding methods.

- Thin Material Limitation: MIG welding may not be suitable for very thin materials, as it can lead to burn-through or warping if not performed carefully.

It is important to evaluate the specific requirements of each welding project and consider these pros and cons to determine if MIG welding is the most suitable technique for the task at hand.

MIG Welding FAQ

- What does MIG stand for in welding? MIG stands for Metal Inert Gas, which is a welding process also known as Gas Metal Arc Welding (GMAW).

- How does MIG welding work? In MIG welding, an electrical current is used to create an arc between the electrode wire and the metal to be welded. The arc melts the wire, which is then deposited to form the weld. A shielding gas is also used to protect the weld from contamination.

- What types of metals can be welded using MIG welding? MIG welding is suitable for welding a variety of metals, including stainless steel, mild steel, aluminum, copper alloys, and some other non-ferrous metals.

- What are the advantages of MIG welding? Some advantages of MIG welding include high productivity, clean welds without slag, versatility in material usage, and relatively easy learning curve for beginners.

- Is MIG welding suitable for beginners? Yes, MIG welding is often recommended for beginners due to its ease of use and shorter learning curve compared to other welding techniques.

- What safety precautions should be taken when MIG welding? When MIG welding, it is important to wear proper safety gear, such as a welding helmet, gloves, and protective clothing. Adequate ventilation and eye protection are also crucial. Additionally, ensuring a safe work environment and proper handling of equipment and materials is essential.

- Can MIG welding be used for outdoor welding? MIG welding can be used outdoors, but precautions should be taken to protect the shielding gas from wind interference, which can affect weld quality. Wind screens or suitable shielding measures may be necessary.

- How do I choose the right MIG welding machine? When selecting a MIG welding machine, consider factors such as the intended application, metal thickness, power requirements, and available features. It is advisable to consult with experts or review product specifications to choose the most suitable machine for your specific needs.

- Can MIG welding be used for thin materials? While MIG welding can be used for thin materials, it requires proper technique and settings to prevent burn-through or distortion. It is recommended to practice on scrap materials and adjust the parameters accordingly.

- What maintenance is required for MIG welding equipment? Regular maintenance includes cleaning the welding gun, checking and replacing consumables (such as contact tips and nozzles), and ensuring proper wire feeding and gas flow. Follow the manufacturer’s guidelines for specific maintenance procedures.

Remember, it is always advisable to consult professional welders or refer to welding guides for specific guidance and further details regarding MIG welding techniques and safety practices.