Flux Cored Arc Welding (FCAW) is an arc welding technique that involves creating an arc between a continuous tubular filler metal electrode and the weld pool.

flux cored arc welding advantages and disadvantages

Welding Town

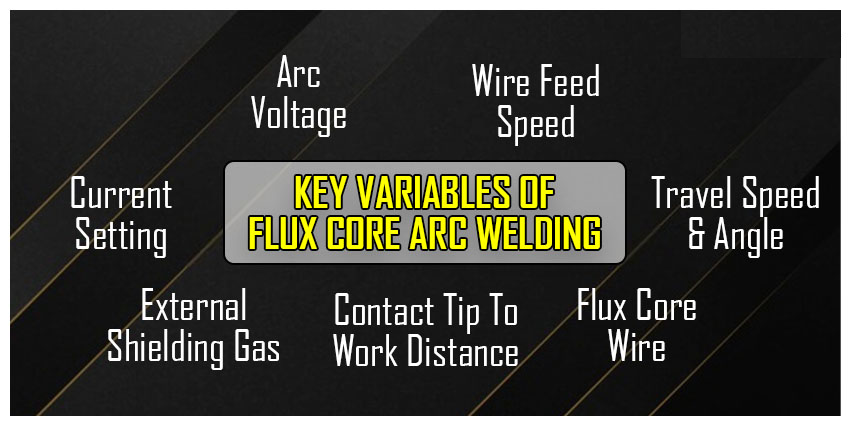

Flux-cored arc welding (FCAW or FCA) is a type of semi-automatic or automatic arc welding. A continuously-fed consumable tubular electrode carrying a flux and a constant-voltage or, less typically, a constant-current welding power source are required for FCAW.

The approach involves shielding gas generated by a flux enclosed within the tubular electrode (a trade name is inner-shield), with or without additional shielding from an outside supplied gas.

Sometimes an externally provided shielding gas is utilized. Still, more often than not, the flux itself is depended on to generate the necessary protection from the atmosphere, creating both gaseous and liquid slag to protect the weld.

Flux core welding is a versatile method of welding that is also super popular and versatile. I wrote this guide describing in full detail the pros and cons of flux core welding. This guide should also help you decide whether flux core welding is right for you, how to get started, and what to expect when starting up. So what are the pros and cons of flux core welding?

Several pros to flux core welding include portability, ease of use, versatility, usability outdoors, and the ability to weld through rust. The cons of flux core welding include the cost of the electrodes, the appearance of the weld bead, spatter, and slag inclusions to name a couple.

Is Flux Core Welding Any Good?

Flux Core Welding, often abbreviated as FCAW, involves the use of a welding wire that is similar in many ways to Metal Inert Gas (MIG) welding except for the fact it includes a flux-cored compound within the wire that has the capability to remove the need for shielding gas.

As for the question of whether this welding method is any good, the answer is yes, provided that the weld bead is being laid down in the recommended circumstances, usually on thicker metals as will be discussed later in this article.

The Flux-cored welder is the field worker’s best friend because they easily move from site to site. They are also easy and straightforward to operate when compared to stick welding. These machines can plug into the standard 120V power system in your home. Since a shielding gas is not needed, you can also use this method to weld in just about any type of weather.

As will be discussed in further detail later, this welder is also one of the best systems for welding galvanized steel. This is because MIG welding is known for being nearly impossible to weld galvanized steel with because of issues with porosity.

One of the few downsides to this technology is the effort it takes to clean up the slag that is a by-product of the welding process. Fortunately, there are ways to mitigate these complaints that will be discussed in further detail below.

Pros of Flux Core Welding

There are several advantages to using flux core welding over other welding types, such as MIG welding. Learning flux core welding will provide you with the opportunity to weld a variety of materials both indoors and outdoors.

Flux Core Welding Can Easily Be Done Outdoors

Shielding gas is of utmost importance in Metal Inert Gas (MIG) Welding in order to keep the molten weld pool from oxygen, nitrogen, and hydrogen in the atmosphere. If the weld pool reacts with these elements, it will become subject to failure from porosity.

Other reasons why you need to use shielding gases when welding include the need to:

- Prevent excessive splatter

- Keep the arc stable

- Control the weld penetration into the base metal

While the solid wires used in MIG welding require shielding gases, flux core wires do not require the use of shielding gases. The mechanics behind this capability will be discussed later in further detail later in this article.

The upshot of this is that flux core wires are popular amongst those who frequently have to repair metal equipment outdoors. Flux core welding is popular at construction sites, in shipyards, and in the farm field.

Cost & Energy Savings

Flux-cored wires will cost at least a little more than a solid wire of the same size. You can see this by comparing the prices of the same-sized wire online.

This is not always apparent because there are many more factors to consider than whether or not the wire requires a shielding gas. Wires of the same size may serve different uses depending on their chemical composition. There are wires made of premium materials that will also cost more.

Still, it has been suggested that you can save quite a bit of money by making the switch to gasless flux core wires if you haven’t done so already. You will begin to really notice the cost savings once you become fully operational.

Depending upon the application, flux core wires can lay down a weld bead at a faster travel speed and with increased deposition rates.

A flux core electrode is capable of depositing up to 25 pounds of wire per hour. A MIG electrode deposits 8 pounds of wire per hour when it is performing at maximum efficiency.

This affects your operating costs because you may have to consume more energy to deposit a pound of solid wire than you would with a flux core wire. Energy savings are perhaps most pronounced when you are welding in position and when you are welding outdoors.

Ability to Weld Rusty Materials

You will find that flux core welding electrodes are much less fussy than solid wire electrodes when it comes to being able to weld metals that have become rusted or otherwise dirtied.

Gas-shielded electrodes usually only perform adequately on base metals that are clean. The presence of extensive rusting and milling is a death knell of sorts to weld quality. This is because gas welding through such contaminants can contribute to excess porosity in the weld bead, enhancing the risk of this weld failing.

Self-shielding flux electrodes, on the other hand, can effectively weld through rust and still produce a quality weld bead. A rusty or scaled surface will not contaminate the weld because the flux contained within the wire is more forgiving of the base metal than a solid wire used in conjunction with a shielding gas would be.

Flux Core Welding Easy to Learn

Flux core welding holds a reputation for being easier to learn.

flux core welding is easier to learn than Stick Welding and TIG Welding. The skill level required to master Flux Core Welding is equivalent to that of MIG Welding.

Flux Core Welding/MIG Welding Machines Are Versatile

You can use the same small welding machine to perform both MIG and flux core welding. The machine can run off 115V electricity that you can get from your home and this welding machine is diverse in the number of purposes that it can serve.

Flux core welding can be used to weld all of the most common metals:

- Carbon steel

- Stainless steel

- Aluminum

This makes the flux core welder ideal for home shops and farms. You also don’t have to worry about hauling around a box of electrodes, since the welding gun is fed by a continuous loop of welding wire. The spools vary in size, with the largest of spoils being large enough to fit in a barrel.

Portability

Once you drop the gas tanks, the MIG welding machines can be moved from one location to the next with ease. MIG welding machines will typically weigh just under 40 pounds if you are going with the welders marketed towards DIYers.

Once you put together all your equipment, including the spool of flux wire, it won’t weigh much more than that. And without having to lug around cylinders of gas, you can easily transport the machine to make emergency repairs on construction or farming equipment.

Cons of Flux Core Welding

There are some drawbacks to flux core welding. For one thing, the electrode itself is more expensive than a solid wire electrode. You will also find that it produces more slag at the weld zone than most other electrodes do.

- General Repairs

- Pipelines

- Shipbuilding

- Manufacturing

- Underwater welding

General Repairs

Flux core welding wires allow for greater penetration of base metals, as compared to other welding techniques. It also allows for greater deposition rates.

FCAW welding, whether self-shielded or gas-shielded, is really best suited for welding thick materials that are at least 20-gauge in thickness. Examples of such materials include stainless steel, carbon steel, low-alloy steel, cast iron, and high nickel alloys.

What Is the Best All-Around Flux Core Welding Wire?

One of the most popular flux core welding wires is the E71T-GS. This is a self-shielding flux core wire that can be used in all positions. It is commonly utilized in auto body repair, farming equipment, tanks, and non-structural frames.

This wire is suitable for welding:

- Thin carbon steels and carbon-manganese steel

- Galvanized steels

- General Field Repairs

- Lap & Fillet Welds on thin gauge materials

he E71T-GS produces a low amount of splatter and it is easy to remove slag from the welded piece. It is tailor-made for routine repairs due to the low penetration of its arc into the base metal. The self-shielding characteristics make it an ideal welding wire for performing field repairs on construction and farming equipment.

This welding wire is also a favorite amongst home workshop welders because it handles like a dream on the 110-volt welding machines that are so often the centerpieces of DIY welding operations.

A Flux Core Wire Well-Suited for Stainless Steel

MIG welding is a welding technique that is commonly used to weld stainless steel. The ER 308L series wire is the most commonly used to weld most stainless steels. High-grade stainless steels are welded with the ER 316L series welding wires and the ER 309L series is used for the welding of stainless steel to other pieces of steel.

Generally, gas-shielded MIG welding wires are used to weld stainless steel pieces with mixtures of Argon and Carbon Dioxide used in the shielding gas. You may also find self-shielding flux core wires useful for welding stainless steel pieces.

The Blue Demon 308LFC-O flux core wire presents welders with the opportunity to weld stainless steel pieces without having to use any shielding gas. It can be used in the flat and horizontal welding positions and is compatible with DC+ (direct current positive).

It can be used for welding 300 series stainless steel up to 308L stainless steel. The 300 series stainless steels are commonly used in the automotive and construction industries. The 308LFC-O flux core wire can also be used to weld 430 series stainless steel.

Flux Core Can Weld Galvanized Steel

Flux core wires are capable of being used to weld galvanized steel pieces, while your typical solid MIG wires cannot do so. The ingredients in flux core wires enable them to successfully weld galvanized steel.

If you are planning on welding galvanized steel, you will want to pay special attention to the specific flux core wire you choose. Some flux core wire types are specifically designed to be compatible with galvanized steel.

The E71T-11 is the recommended flux core wire for welding galvanized steel pieces. It also works well with thin-gauge mild steels.

Is MIG Welding Better Than Flux Core?

Flux core welding is a lot more convenient than MIG welding because you do not need to use a shielding gas to keep the weld bead stable. Flux core welding is surely the preferred method when welding outdoors. There are circumstances in which MIG welding is the more suitable method.

One method is not necessarily better than the other but there are circumstances in which you may find one solid wire MIG welding more suitable than flux core welding.

Circumstances in which MIG welding may be the way to go:

- If the metal that you are welding is less than 3/16” in thickness

- If creating a weld with a clean finish is of importance to you

- You are looking to lay down a weld bead that you will be able to easily paint over without having to remove excess slag

It can be nearly impossible to use MIG welding wires to weld galvanized steel.

You will find that flux-cored wires are significantly more effective for welding galvanized steel. Nearly every piece of metal that was designed to be kept outdoors, including chain link fence, is galvanized.

Flux core wires are able to successfully weld galvanized pieces because of the chemical composition of the flux. Scavengers and fluxing agents are able to refine the weld. They help to prevent the porosity and cracking issues that are observed when a piece of galvanized metal is welded using a MIG wire.

Is TIG Welding Better Than Flux Core?

TIG stands for Tungsten Inert Gas, a welding process that is officially called Gas Tungsten Arc Welding (GTAW). The tungsten electrode used in the process is a non-consumable electrode.

Like MIG welding, this is a welding technique that requires the use of shielding gas in order to keep the weld pool from deteriorating due to porosity issues. Argon is the inert gas that is often used with TIG Welding.

The fact that the tungsten electrode is non-consumable allows the welder to bond metal pieces together without having to use a filler metal, even though filler metals are often used anyway. TIG welding can be used in metal-to-metal welds and results in a cleaner weld zone.

One caveat to TIG welding is that it requires more refined welding skills than MIG and flux core welding. You must take care to not overheat the weld as it can result in stress cracks and other similar deficiencies in the finished weld.

TIG welding is also not very effective at welding thicker metal pieces. If you are welding a piece that is approximately 3/16” thick or thicker, then flux core welding will be your best bet. Tig welding was invented to weld thin metals for applications like aerospace. It is fantastic for some metals and particular thicknesses, but not all. It also works best when you are able to back-purge when your TIG welding job.

All in all, flux core welding is a unique, simple-to-learn, versatile welding technique that can work where other techniques cannot. If you work outside primarily, and in the positions mentioned above, this would be worth checking out for welding jobs around the house or farm. Thanks for reading and keep stacking dimes!